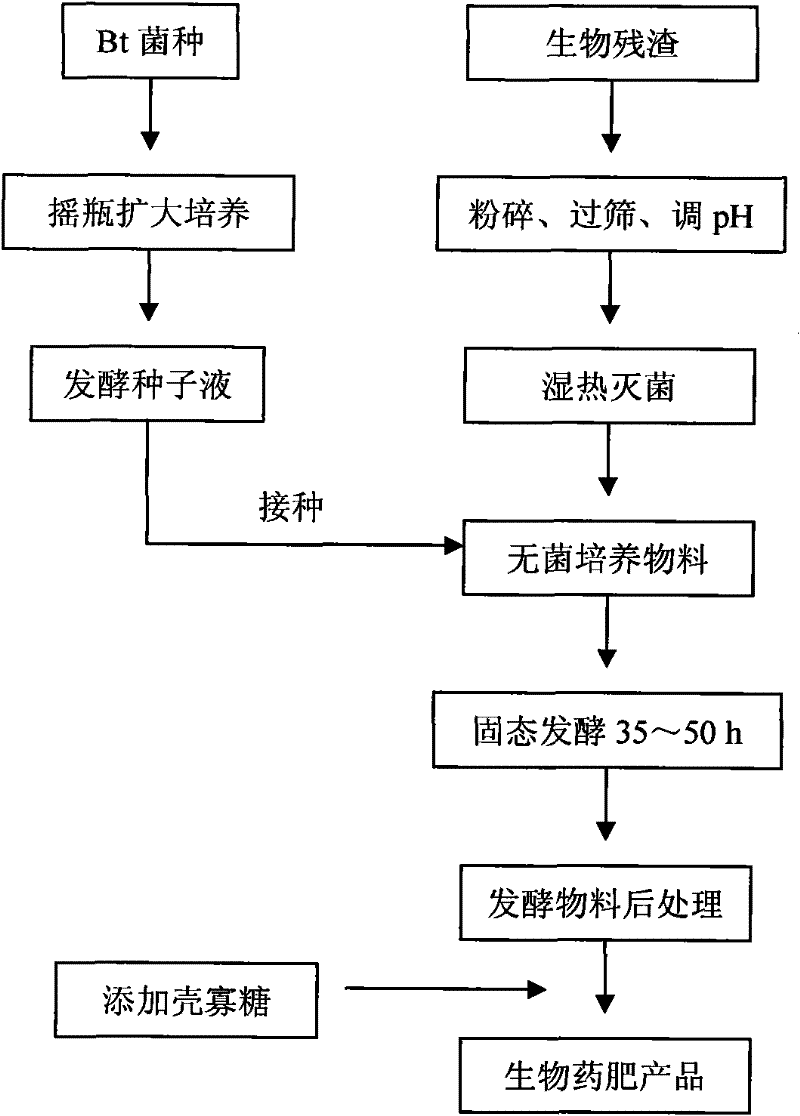

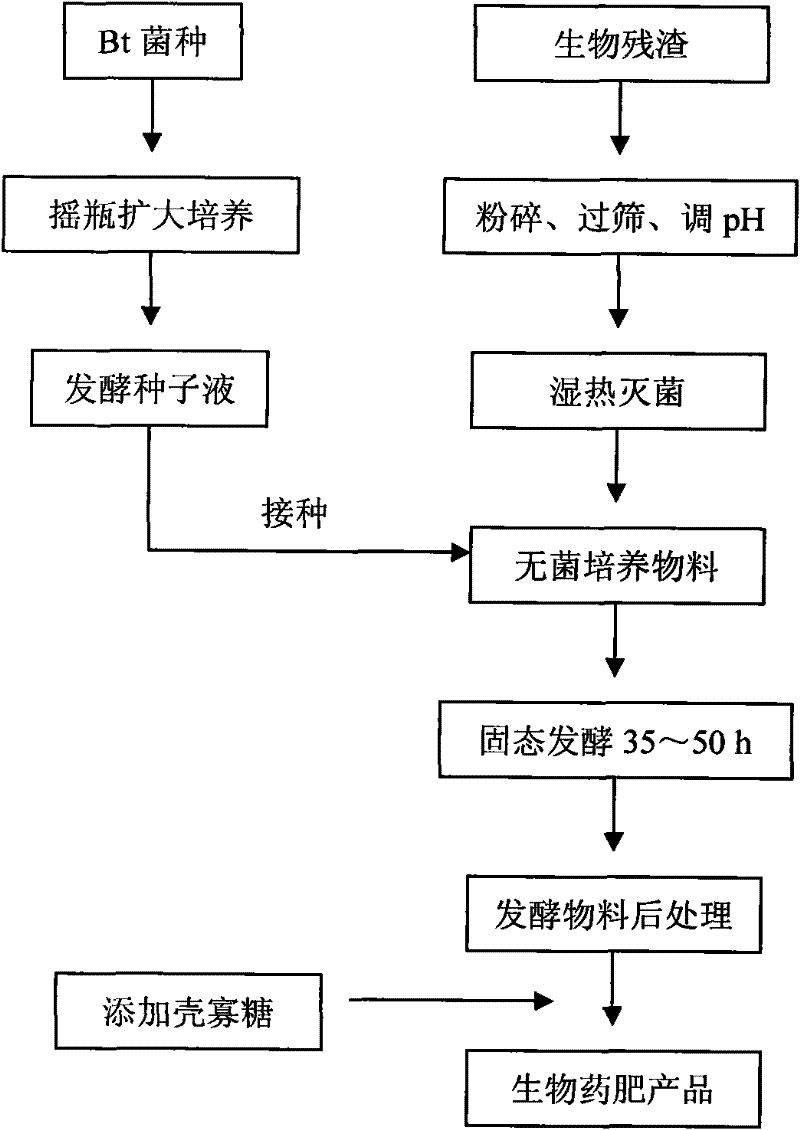

Method for producing biological medicament fertilizer product through solid state fermentation of biological residue

A technology of solid-state fermentation and biomedical fertilizer, applied in application, fertilization device, fertilizer mixture, etc., to achieve unique effects of regulating plant metabolism, low cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, take asparagus leftovers as raw material to prepare biological medicine fertilizer

[0036] (1) Pretreatment of raw materials: the asparagus scraps are crushed to 20 meshes, the initial water content of the asparagus scraps is adjusted to 65%, and the inorganic salt KH is added 2 PO 4 0.2%, MgSO 4 ·7H 2 O 0.1%, CaCO 3 1.0%, fully stir and mix, adjust the pH to 7.0, and after 20-30 minutes of moist heat sterilization, obtain sterile culture materials, cool to about 30°C for later use;

[0037] (2) Bacterial strain expansion culture: pick a ring of Bt bacterial lawn from the bacillus thuringiensis slant culture medium, inoculate in 100mL sterilized beef extract peptone liquid medium (beef extract 0.3%, peptone 1%, NaCl 0.2%) , pH7.0~7.2), carry out shaking flask culture, the culture conditions are: temperature 30 ℃, rotating speed 200 rpm, culture 7~8 hours, as Bt bacteria seed liquid;

[0038] (3) Solid-state fermentation: inoculate Bt seed liquid in...

Embodiment 2

[0040] Embodiment 2, take asparagus leftovers as raw material to prepare biological medicine fertilizer

[0041] (1) Pretreatment of raw materials: the asparagus scraps are crushed to 40 meshes, the initial water content of the asparagus scraps is adjusted to 70%, and KH 2 PO 4 0.075%, MgSO 4 ·7H 2 O 0.2%, CaCO 3 0.5% Stir and mix well, adjust the pH to 7.2, and after 20-30 minutes of damp heat sterilization, obtain sterile culture materials, cool to about 30°C for later use;

[0042] (2) Bacterial classification expansion culture: with embodiment 1;

[0043] (3) Solid-state fermentation: inoculate the Bt seed liquid into the aseptic culture material, stir and mix, and carry out solid-state fermentation. The fermentation conditions are: temperature 32°C, humidity 85%, ventilation rate 1: 2, during 11 hours of fermentation, Reduce the fermentation temperature to 27°C, and the fermentation time is 40 hours;

[0044] (4) Post-treatment of fermented materials: the fermente...

Embodiment 3

[0045] Embodiment 3, using asparagus residue as raw material to prepare biomedical fertilizer

[0046] (1) Pretreatment of raw materials: asparagus residues are crushed to 40 meshes, the initial water content of asparagus residues is adjusted to 75%, and inorganic salt KH 2 PO 4 0.2%; MgSO 4 ·7H 2 O 0.2%; MnSO 4 ·H 2 O 0.002%; FeSO 4 ·H 2 O0.002%; ZnSO 4 ·H 2 O 0.002%, CaCO 3 1.0%, fully stir and mix, adjust the pH to 7.4, and after 20-30 minutes of moist heat sterilization, obtain sterile culture materials, cool to about 30°C for later use;

[0047] (2) Bacterial classification expansion culture: with embodiment 1;

[0048] (3) Solid-state fermentation: Inoculate the Bt seed liquid into the aseptic culture material, stir and mix, and carry out solid-state fermentation. The fermentation conditions are: temperature 30°C, humidity 95%, ventilation rate 1: 1.2, in 10 hours of fermentation, Reduce the fermentation temperature to 26°C, and the fermentation time is 40 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com