Biological biodegradable self-control slow-releasing fertilizer and preparation method thereof

A slow-release fertilizer and biological technology, applied in fertilizer mixtures, nitrogen fertilizers, fertilization devices, etc., can solve the problems of poor nutrient controlled release performance, unfavorable food crops promotion and application, unfavorable handling, etc., and achieve good controlled release performance and degradability. The effect of expanding the scope of applicable crops and improving nitrogen use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

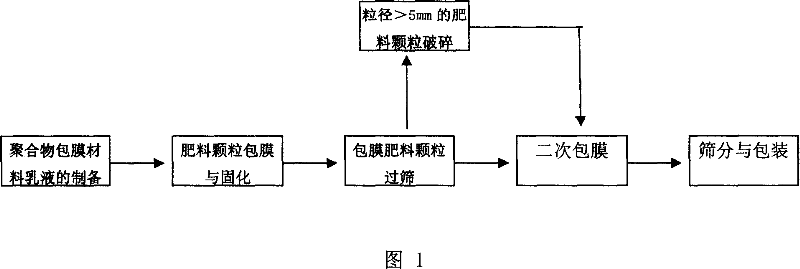

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of water-soluble polymer coating material emulsion: cellulose in weight ratio: oxidized starch: polyvinyl alcohol: polyurethane prepolymer: epoxy resin E44: epoxy resin curing agent T593: crosslinking Agent N-methylolacrylamide: emulsifier Tween 80: initiator potassium persulfate: deionized water is 35:2:6:8:9:3:2:0.15:0.002:51 (unit: gram) Weigh each component of the water-soluble high molecular polymer respectively, then mix cellulose (hydroxymethyl cellulose: nitrocellulose: the mixing weight ratio between carboxymethyl cellulose is 1: 1: 1), Oxidized starch, polyvinyl alcohol (average degree of polymerization 1700-1800, molecular weight 84000-89000 Daltons), polyurethane prepolymer, epoxy resin E44, epoxy resin curing agent T593, N-methylolacrylamide Put it into a container filled with Tween 80 and deionized water, and shear and emulsify at 8000r / min for 0.5h at 25°C to obtain an emulsion; / ml solution as an initiator; adjust the pH value of the emu...

Embodiment 2

[0054] (1) Preparation of water-soluble polymer coating material emulsion: cellulose in weight ratio: oxidized starch: polyvinyl alcohol: polyurethane prepolymer: epoxy resin E44: epoxy resin curing agent T593: crosslinking Agent N-methylolacrylamide: emulsifier Tween 80: initiator potassium persulfate: deionized water is 28: 1.5: 5: 6: 14: 2.5: 1.5: 0.12: 0.0015: 50 (unit: gram) Weigh each component of the water-soluble polymer respectively, then cellulose (the mixing weight ratio between hydroxymethyl cellulose: carboxymethyl cellulose is 1: 1), oxidized starch, polyvinyl alcohol (the average degree of polymerization is 550-650, and the molecular weight is 27000-32000 Daltons), polyurethane prepolymer, epoxy resin E44, epoxy resin curing agent T593, N-methylolacrylamide poured into Tween 80 and deionized water container, at 24 ° C, shear emulsification at 9000r / mim speed for 0.6h to obtain an emulsion; at the same time, use the reserved deionized water to make potassium pers...

Embodiment 3

[0060] Pour 75g hydroxymethylcellulose, 75g nitrocellulose, 5g oxidized starch, 20g polyvinyl alcohol, 25g polyurethane prepolymer, 30g epoxy resin (E44), 10g T593, 5g N-methylolacrylamide into the container In a 1000ml beaker with 0.5g Tween 80 and 250ml deionized water, high-speed shear emulsification at room temperature for 0.5h, while using 5ml deionized water to make a solution of 0.005g potassium persulfate as an initiator. Use a pH adjuster to adjust the pH of the emulsion to 7.5, take 1 / 10 and 1 / 5 of the initiator solution of the above emulsion and add it to a four-necked bottle or a reaction kettle, blow nitrogen, raise the temperature to 75°C, and after 20 minutes, add the remaining The emulsion (mixed with 4 / 5 initiator solution) is added dropwise within 2 hours, and the reaction is continued for 3 hours to end the reaction to obtain a water-soluble high polymer coating material emulsion with cellulose as the main component.

[0061]Add urea or compound fertilizer g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com