Supporting roller surface deoiling system

A technology for supporting rollers and oil systems, which is applied in the directions of removing smoke and dust, keeping the roller equipment in an effective state, cleaning methods and appliances, etc. Oil effect, easy operation and maintenance, reliable action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

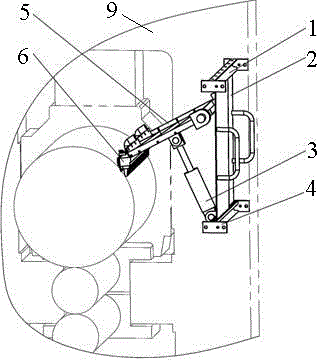

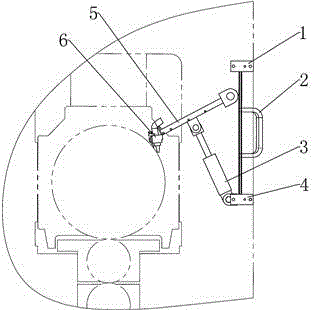

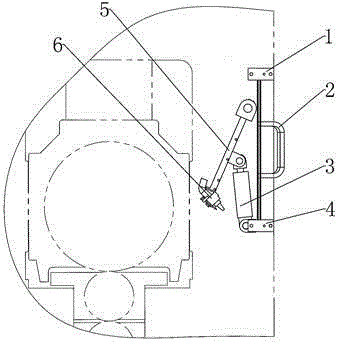

[0025] This embodiment provides a figure 1 The shown supporting roller surface degreasing system includes degreasing beam 6, oil retaining plate frame, swing oil cylinder 3, lower track beam 4, protective door 2 and upper track beam 1, and the upper track beam 1 and lower track beam 4 are both Horizontally fixed on the archway 9 on both sides of the frame, the end of the piston rod of the swing cylinder 3 is hinged on the lower surface of the oil deflector frame, and the cylinder body of the swing cylinder 3 is hinged on the lower track beam 4 through the hinge hole. The protective door 2 is arranged between the upper track beam 1 and the lower track beam 4 through a sliding connection, one end of the oil retaining plate frame is connected with the oil removal beam 6, the other end is hinged with the arches 9 on both sides of the frame, and the end is connected with the guard Door 2 connects.

[0026] Such as figure 1 As shown, the back-up roll surface degreasing system is i...

Embodiment 2

[0029] On the basis of Embodiment 1, this embodiment provides a backup roll surface oil removal system, the top of the oil deflector frame is provided with a plurality of inclined plates 10, and the plurality of inclined plates 10 are distributed in a herringbone shape , the joint of the oil retaining plate frame and the lower end of the swash plate 10 is provided with an oil drain hole.

[0030] Oil baffle frame 5 upper and lower all play the effect of oil baffle. A plurality of sloping plates 10 are distributed in a herringbone shape to guide the oil, and guide the oil dropped on the top of the oil baffle frame 5 to flow out through the oil drain holes on both sides. Because the oil baffle frame 5 is hinged with the archways 9 on both sides of the frame, the width is greater than the width of the plate, and the rolling oil flows to the both sides of the plate through the drain hole, and can not fall on the plate. The structure of the oil baffle frame 5 is as Figure 4 show...

Embodiment 3

[0032] On the basis of Embodiment 1, this embodiment provides a backup roll surface degreasing system. The degreasing beam 6 includes a beam, a pressure plate 11, an elastic oil scraper 12, an air knife 7, and is arranged at equal intervals along the beam. A plurality of short air intake pipes 8, one end of the beam is provided with a mounting plate 15 connected to the oil deflector frame, and the other end is provided with a pressure plate 11, and the elastic oil scraper 12 is arranged between the pressure plate 11 and the end surface of the beam , the air knife 7 is arranged on the lower end surface of the beam, the short air inlet pipe 8 is arranged on the top surface of the beam and communicates with the air knife 7, and the short air inlet pipe 8 is connected to the compressed air pipeline. The structure of degreasing beam 6 is as Figure 5 shown.

[0033] The compressed air blown out by the oil removal beam 6 through the short intake pipe 8 blocks most of the rolling oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com