Low-grade solid potassium chloride ore solid-to-liquid method

A potassium chloride ore, low-grade technology, applied in the field of salt chemical industry, can solve the problems of low grade of solid potassium ore, and achieve the effects of improving the utilization rate, improving the repeated utilization rate and saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

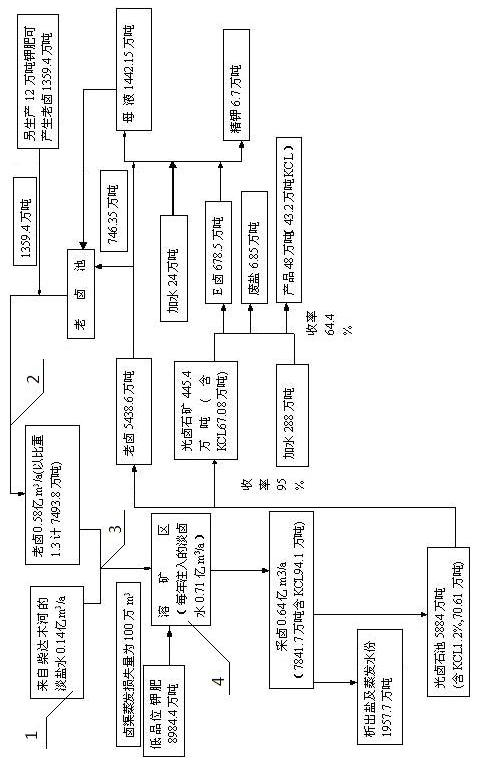

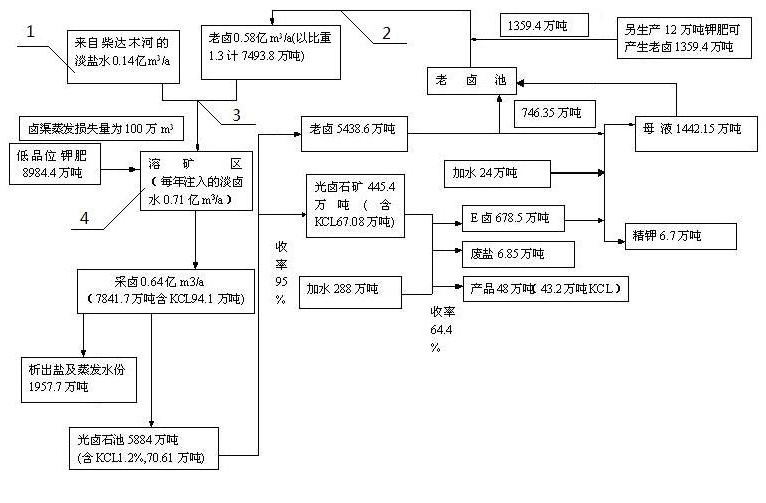

[0033] The technical scheme of the present invention is mainly a project for dissolving low-grade solid potassium chloride in the east mine section of the Chaerhan Salt Lake Railway.

[0034] Technical scheme of the present invention : The proportion of fresh water and brine; the method of dissolving ore; the path of dissolving ore. It is designed to inject 245 million cubic meters of desalinated brine per year. According to the dewatering area of the Chaerhan Salt Lake Mine, the amount of recharged fresh water and tail brine required is 9.92×10 8 m 3 / year and 3.97×10 9 m 3 / year. According to the mining of 124 million cubic meters of ore-forming brine every year, the actual desalinated brine added to the mining area is 121 million cubic meters per year. It can be seen that 41 years of continuous brine irrigation is required, so that the brine mining balance can be achieved, so that the depth of brine mining is from The current 16 meters has been reduced to 4 meters. ...

Embodiment 2

[0054] The technical scheme of the present invention is mainly a project for dissolving low-grade solid potassium chloride in the east mine section of the Chaerhan Salt Lake Railway.

[0055] Technical scheme of the present invention : The proportion of fresh water and brine; the method of dissolving ore; the path of dissolving ore. It is designed to inject 245 million cubic meters of desalinated brine per year. According to the dewatering area of the Chaerhan Salt Lake Mine, the amount of recharged fresh water and tail brine required is 9.92×10 8 m 3 / year and 3.97×10 9 m 3 / year. According to the mining of 124 million cubic meters of ore-forming brine every year, the actual desalinated brine added to the mining area is 121 million cubic meters per year. It can be seen that 41 years of continuous brine irrigation is required, so that the brine mining balance can be achieved, so that the depth of brine mining is from The current 16 meters has been reduced to 4 meters. ...

Embodiment 3

[0075] The technical scheme of the present invention is mainly a project for dissolving low-grade solid potassium chloride in the east mine section of the Chaerhan Salt Lake Railway.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com