Positive electrode collector recycling treatment method of waste lithium ion battery

A lithium-ion battery and cathode current collector technology, which is applied in the field of waste lithium-ion battery cathode current collector recovery and treatment, can solve the problems of high energy consumption, large amount of wastewater treatment, and high reagent consumption, so as to reduce pollution and avoid lye discharge , Reagent consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

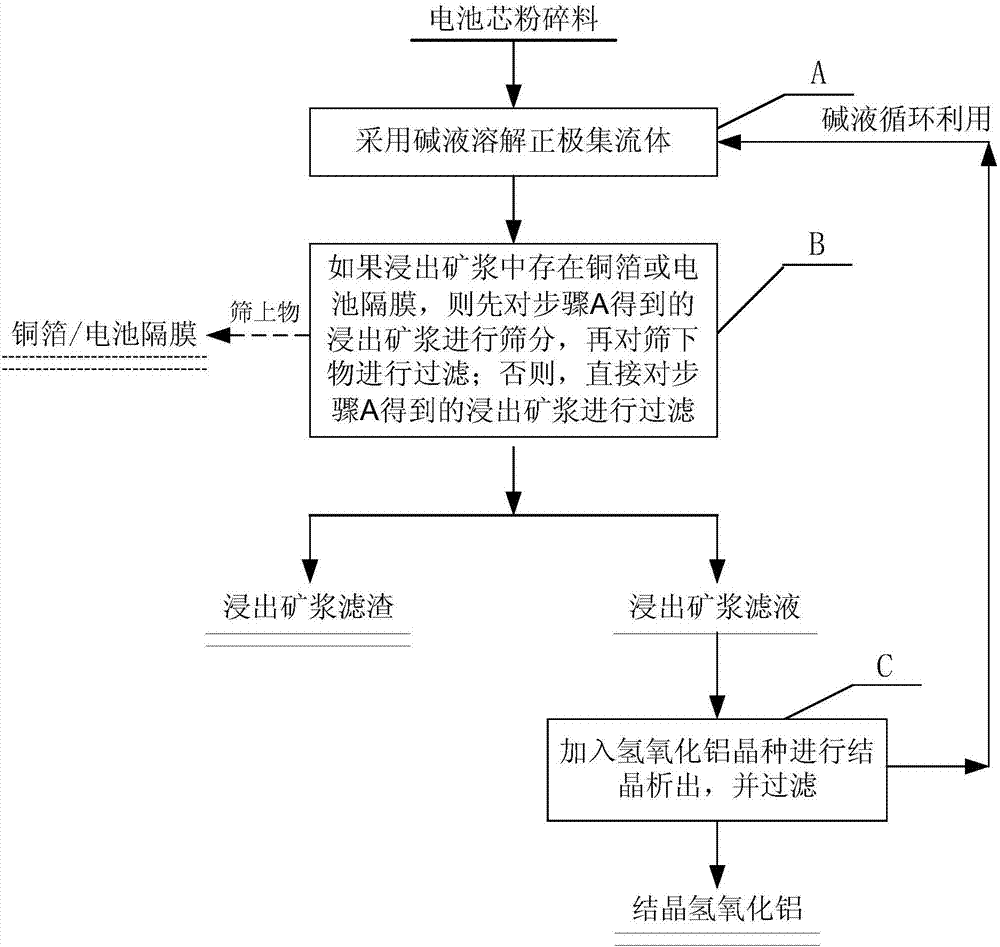

[0044] A method for reclaiming and treating a positive electrode collector of a waste lithium-ion battery, comprising the following steps:

[0045] Step a1, soaking the waste lithium ion battery in a 5% NaCl solution by mass fraction for 24 hours, fully discharging, then drying the fully discharged waste lithium ion battery at 60°C, and then mechanically dismantling, removing A steel shell and a plastic shell are obtained to obtain battery cores, and then the battery cores are crushed into crushed battery core materials with a particle size of 5-10 mm. Through analysis and detection: the Al content in these crushed battery core materials is 5.46wt%.

[0046] Step b1, adding 100 g of the crushed battery core material into the lye to dissolve the positive current collector, the concentration of the lye is 150 g / L, the initial Al concentration in the lye is 25 g / L, and the temperature for dissolving the positive current collector is 95°C , the stirring speed for dissolving the p...

Embodiment 2

[0051] A method for recovering and processing the positive electrode current collector of waste lithium-ion batteries. The battery core crushed materials of waste lithium-ion batteries provided by a certain factory do not include copper foil and battery separators in these battery core crushed materials, and the Al content in these battery core crushed materials For 2.28wt%, it can specifically include the following steps:

[0052] Step a2, adding 100 g of the crushed battery core material into the lye to dissolve the positive current collector. The lye is the lye produced in step e1 of Example 1 of the present invention, and the temperature for dissolving the positive current collector is 95°C. The stirring speed of the positive electrode current collector is 500 rpm, and the time for dissolving the positive electrode current collector is 2 hours, so as to obtain leached pulp. Since the crushed battery core material used in step a2 does not include copper foil and battery sep...

Embodiment 3

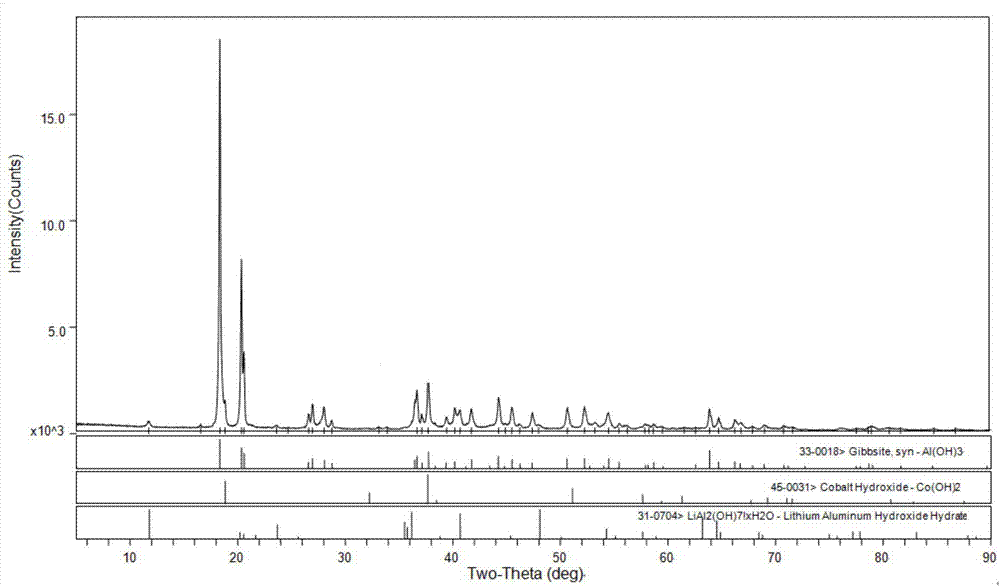

[0056] A method for recycling and treating the positive electrode current collector of waste lithium-ion batteries. The positive electrode scraps produced in a lithium-ion battery production process in a certain factory are used as battery core crushed materials. The Al content in these battery core crushed materials is 8.30wt%. Specifically, it can include The following steps:

[0057] Step a3, adding 100 g of the crushed battery core material into the lye to dissolve the positive current collector. The lye uses the lye produced in step c2 of Example 2 of the present invention, and the temperature for dissolving the positive current collector is 95°C. The stirring speed of the positive electrode current collector is 500 rpm, and the time for dissolving the positive electrode current collector is 2 hours, so as to obtain leached pulp. Since the battery core pulverized material used in step a3 is the positive electrode scrap produced in the lithium-ion battery production proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com