Method for utilizing circulation water in aluminum hydroxide or aluminum oxide production process

A technology of aluminum hydroxide and production process, which is applied in the direction of aluminum oxide/aluminum hydroxide, etc., can solve the problems of increased labor intensity of employees, excessive alkalinity of effluent sewage, and pollution of the surrounding environment, so as to reduce labor intensity and danger, Reduce fresh water consumption and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

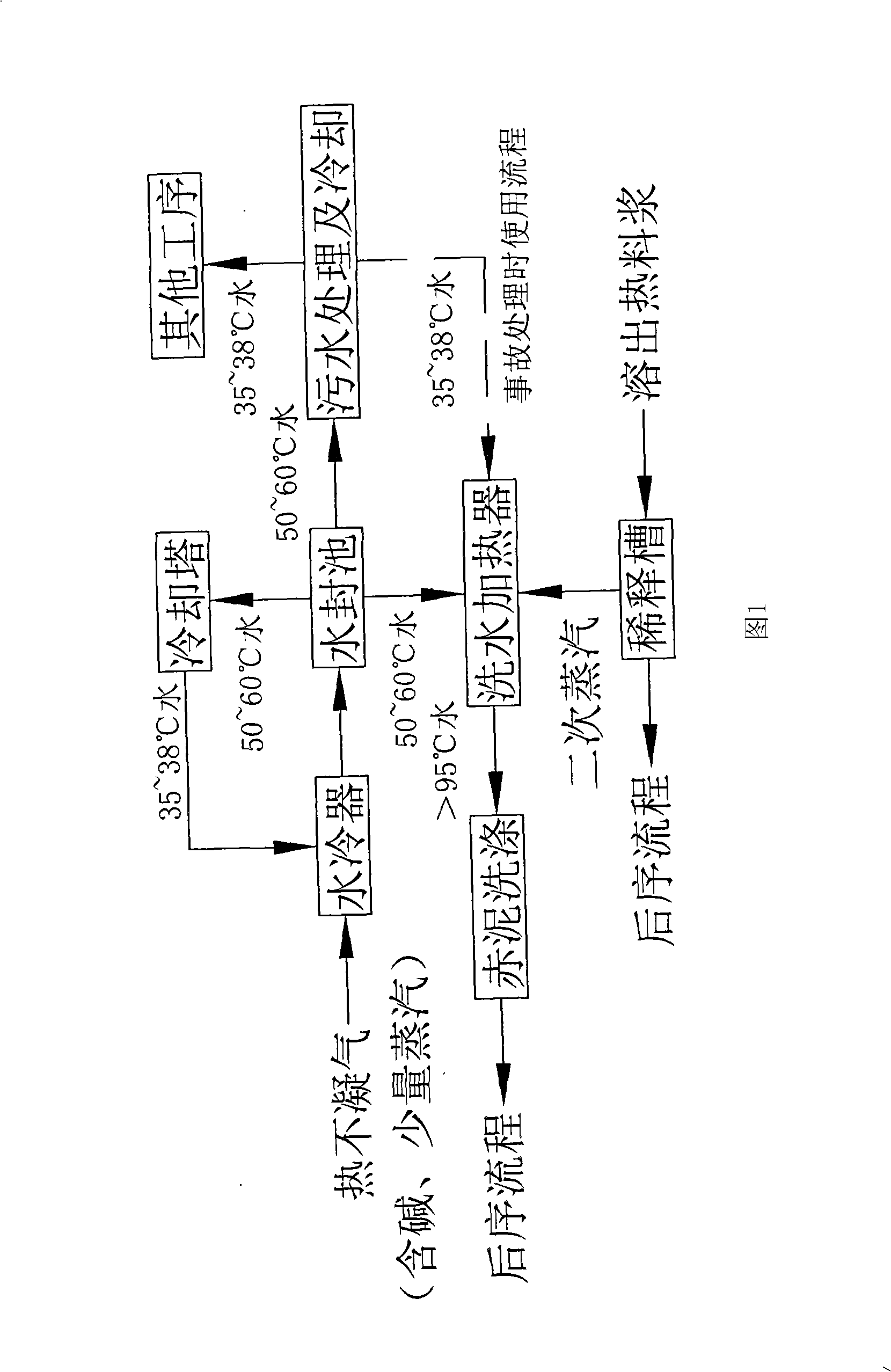

[0009] The present invention comprises the following steps: the water (60m 3 / h or so) except for a small part used as white mud washing liquid, it is used for circulating water after cooling (the temperature does not exceed 38°C in summer and 35°C in winter), due to the need for red mud washing and settlement in the settling tank , the temperature needs to be raised to 95°C. Therefore, after passing through the washing water heater on the upper part of the dilution tank, the circulating water of the mother liquor evaporation system will bring the hot non-condensable gas (including heat, steam, alkali) into the water cooler of the mother liquor evaporation system. A circulating water feed pump is installed on the water seal pool under the water cooler, and the hot circulating water from the water cooler is directly sent to the washing water heater on the dilution tank. When the water temperature reaches 95°C-100°C, it is sent for washing with red mud; evaporated in the mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com