Method for recovering gold and silver from waste gold/silver-containing activated carbon

A technology of activated carbon and activated carbon adsorption, which is applied in the direction of improving process efficiency and reducing gas emissions, can solve problems affecting the health of employees, discourage promotion, waste of precious metals, etc., and achieve the goal of easy implementation and promotion, easy promotion and resource saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

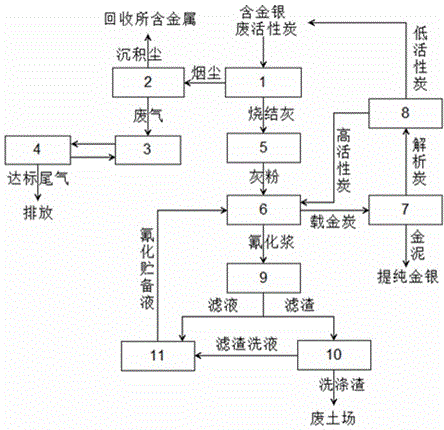

[0017] Example 1:

[0018] The method for recovering gold and silver from gold and silver-containing waste activated carbon of the present invention is as follows: send gold and silver-containing waste activated carbon to ashing furnace 1, fully burn by spontaneous combustion under oxygen-enriched conditions, and sinter into blocks, and the smoke generated is first passed through the ashing furnace. The dust chamber is bagged to collect dust, and the collected dust is analyzed and tested to recover metals according to the composition. The exhaust gas after dust collection is introduced into the lye countercurrent spray tower 3 through the fan, and the mass concentration of 10% hydrogen in the lye storage tank 4 is used The sodium oxide solution is circulated and sprayed to remove waste gases such as carbon dioxide produced by combustion; the agglomerate is sent to the pulverizer 5 for grinding, and after the particle size is finer than 300 mesh, it is transferred to the cyanide...

Example Embodiment

[0019] Example 2:

[0020] The method for recovering gold and silver from gold and silver-containing waste activated carbon of the present invention is as follows: send gold and silver-containing waste activated carbon to ashing furnace 1, fully burn by spontaneous combustion under oxygen-enriched conditions, and sinter into blocks, and the smoke generated is first passed through the ashing furnace. The dust chamber is bagged to collect dust, and the collected dust is analyzed and tested to recover metals according to the composition. The exhaust gas after dust collection is introduced into the lye countercurrent spray tower 3 through the fan, and the mass concentration of 10% hydrogen in the lye storage tank 4 is used The sodium oxide solution is circulated and sprayed to remove waste gases such as carbon dioxide produced by combustion; the agglomerate is sent to the pulverizer 5 for grinding, and after the particle size is finer than 300 mesh, it is transferred to the cyanide...

Example Embodiment

[0021] Example 3:

[0022] The method for recovering gold and silver from gold and silver-containing waste activated carbon of the present invention is as follows: send gold and silver-containing waste activated carbon to ashing furnace 1, fully burn by spontaneous combustion under oxygen-enriched conditions, and sinter into blocks, and the smoke generated is first passed through the ashing furnace. The dust chamber is bagged to collect dust, and the collected dust is analyzed and tested to recover metals according to the composition. The exhaust gas after dust collection is introduced into the lye countercurrent spray tower 3 through the fan, and the mass concentration of 10% hydrogen in the lye storage tank 4 is used The sodium oxide solution is circulated and sprayed to remove waste gases such as carbon dioxide produced by combustion; the agglomerate is sent to the pulverizer 5 for grinding, and after the particle size is finer than 300 mesh, it is transferred to the cyanide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com