Scanning type pipeline leakage detecting mechanism

A leak detection and scanning technology, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as safety hazards, perforation, and accelerated pipeline wall perforation, so as to improve the accuracy and stability of pressure measurement, Effects of improving safety performance and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

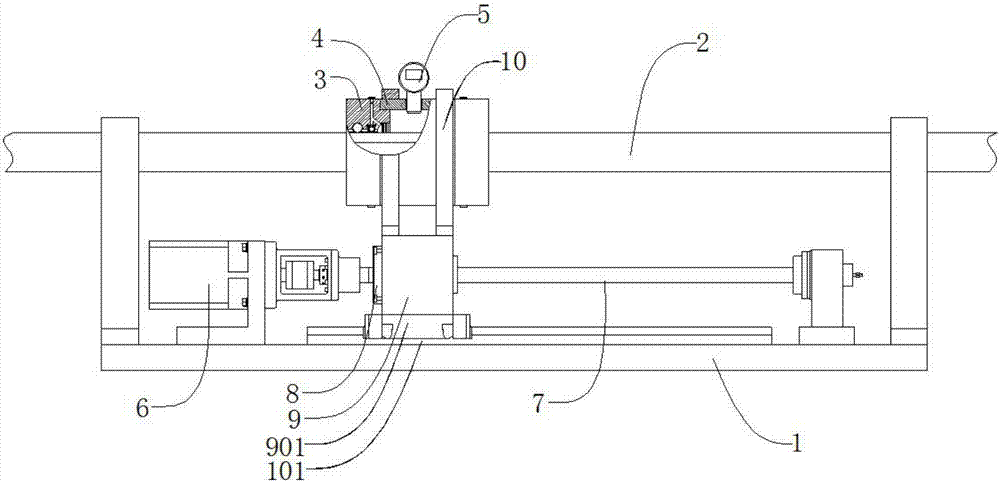

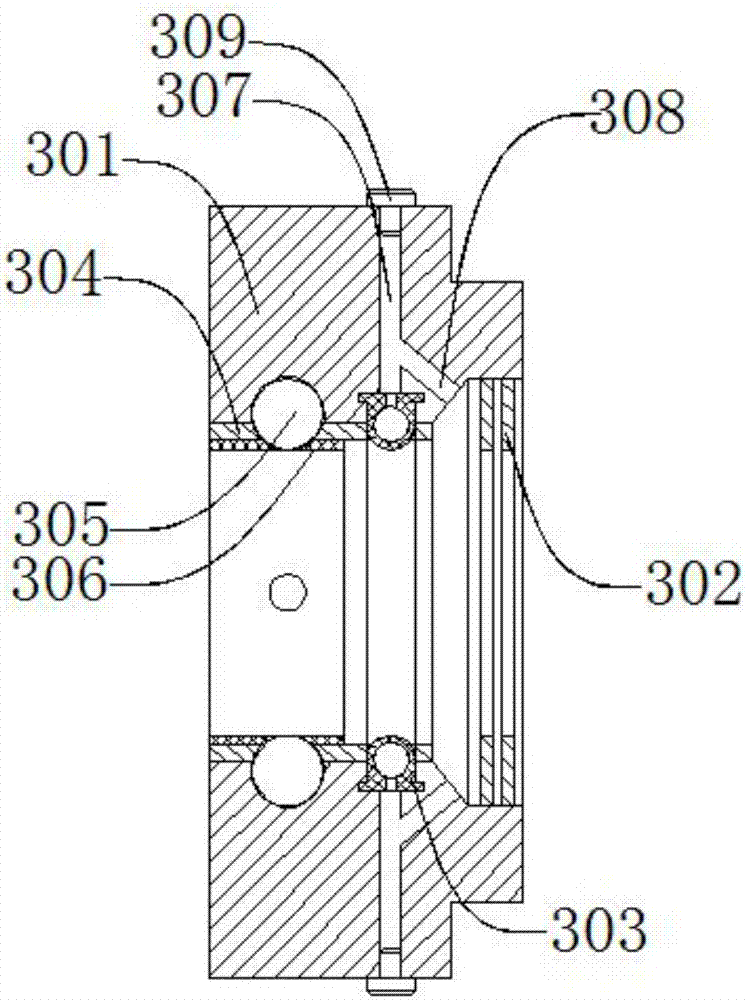

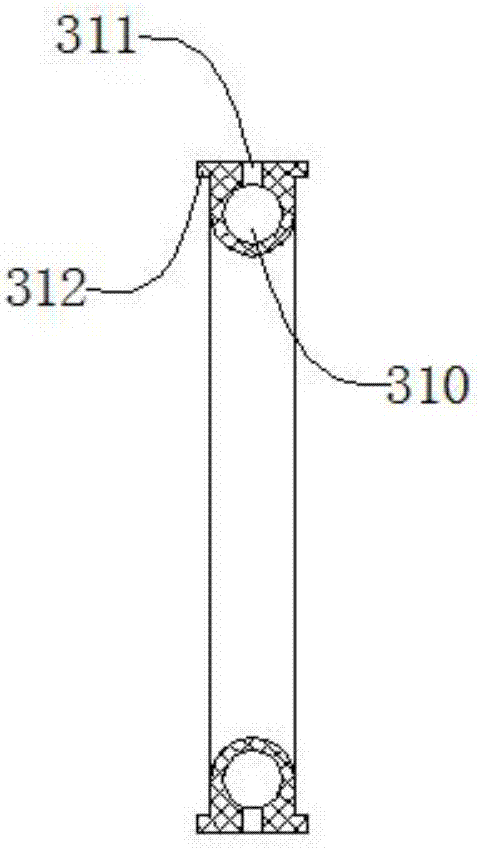

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a scanning pipeline leakage detection mechanism includes a base 1, a pipeline 2, a sealing mechanism 3 symmetrically arranged in two pieces along the pipeline 2, a connecting pipe 4, a pressure gauge 5, a servo motor 6, and a screw 7 , feed nut 8, sliding seat 9, support frame 10, the sealing mechanism 3 is located on the outside of the pipeline 2, the sealing mechanism 3 is connected to the pipeline 2 with a gap, and the connecting pipe 4 is located in the two symmetrically arranged sealing Between the mechanisms 3, the connecting pipe 4 is connected to the sealing mechanism 3 by welding, the pressure gauge 5 is located outside the connecting pipe 4, the pressure gauge 5 is threadedly connected to the connecting pipe 4, and the servo motor 6 is located on the The upper end of the base 1, the servo motor 6 is threadedly connected with the base 1, the lead screw 7 is located on one side of the servo motor 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com