Automatic control system and method for coal slime flocculation settling

An automatic control system, slime water technology, applied in the field of automatic control system and control of coal slime water flocculation sedimentation, coal slime water flocculation sedimentation control system and fuzzy control, can solve the problem of difficult to obtain stable control effect, feedback signal lag dosing time, The turbidity fluctuates up and down, etc., to overcome the unstable or even out-of-control control effect, improve the stability, and avoid the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

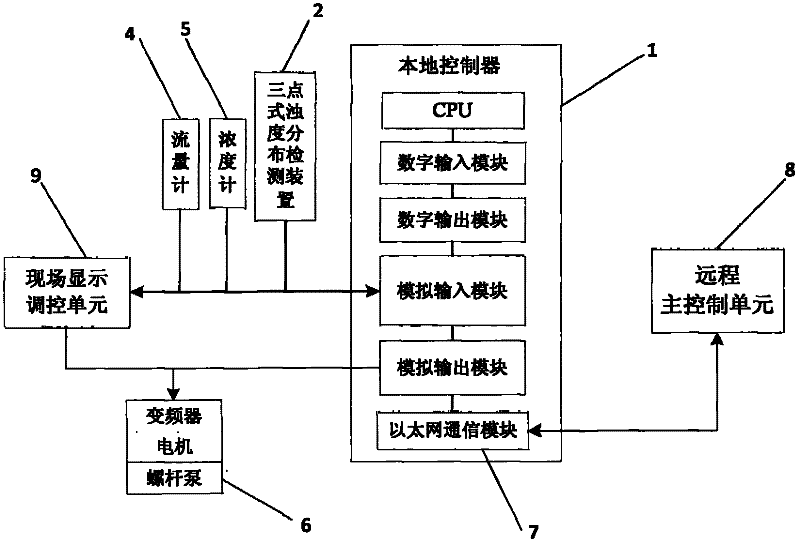

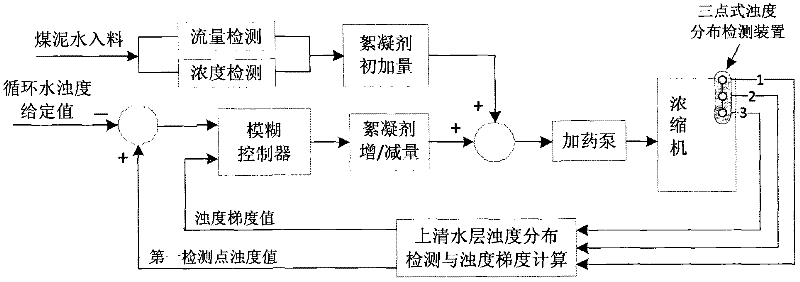

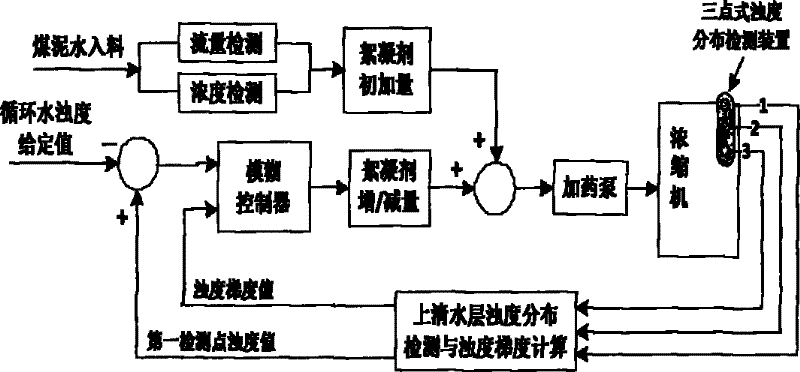

[0021] The system detects the real-time flow rate and real-time concentration value of the concentrator feed through the flow meter 4 and the concentration meter 5 on the local controller 1, and calculates the corresponding real-time initial addition of flocculant according to the flocculation and sedimentation agent system; the three-point turbidity The distribution detection device 2 is vertically installed on the clear water layer on the thickener, the first point is flush with the overflow hole of the thickener, the second point is 500mm away from the first point, and the third point is 1000mm away from the second point; The deviation between the turbidity value and the turbidity given value is used as one of the inputs of the fuzzy controller 3, and the turbidity gradient value calculated from the measured turbidity distribution is used as the second input of the fuzzy controller 3, and the speed control amount of the screw pump is As the output of the fuzzy controller 3, ...

Embodiment approach 2

[0023]The remote main control unit 8 receives the sensor parameters transmitted from the local controller 1 through the Ethernet communication module 7, and performs data analysis and flocculation and settlement effect analysis on the industrial computer of the remote main control unit 8. According to the analysis results, the fuzzy controller 3 The output coefficient fuzzy rules are adjusted, and the adjusted part is sent back to the local controller 1 by the Ethernet communication module 7, and the local controller 1 implements control after online parameter modification or rule modification. Others are the same as Embodiment 1.

Embodiment approach 3

[0025] The system uses a three-point turbidity distribution detection device 2 to obtain the turbidity distribution in the clear water layer on the concentrator, and uses the flow meter 4 and the concentration meter 5 to detect the real-time flow and real-time concentration values of the concentrator feed, and these detection quantities are displayed on site for regulation The real-time display on the unit 9 also shows the dosage of flocculant corresponding to the output frequency of the frequency converter. Frequency manual intervention adjustment, increase or decrease the dosage of flocculant to ensure that the turbidity of circulating water reaches the standard. Others are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com