Statically indeterminate modular main beam amplitude adjustable low-frequency vibration tension and relaxation screen

A low-frequency vibration, ultra-statically indeterminate technology, applied in the direction of filtration, chemical instruments and methods, solid separation, etc., can solve the problems of strength limitation, short service life of vibrating screen surface, single linear motion, etc., to prevent local stress concentration, The effect of reducing the dead weight of the structure and avoiding concentrated loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

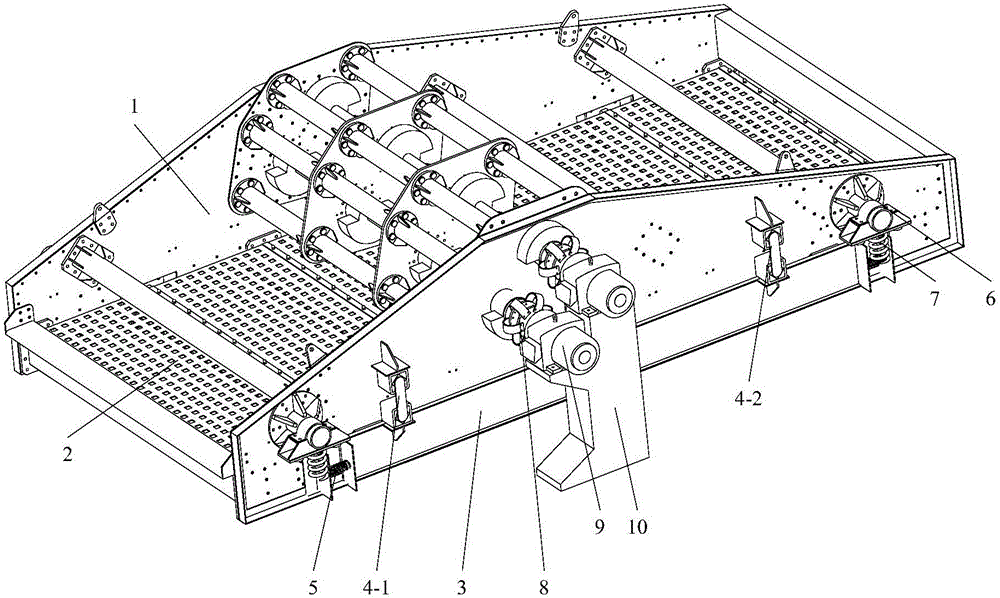

[0045] Embodiment 1, as figure 1 As shown, the ultra-statically indeterminate modular main beam amplitude adjustable low-frequency vibration relaxation screen of the present invention is mainly composed of a screen body 1, an elastic screen surface 2, a floating screen frame 3, a rubber hinge 4, an amplitude limit spring 5, and a spring support Seat 6, damping spring 7, shaft coupling 8, motor 9, support 10 and super statically indeterminate excitation main beam. The sieve body 1 is installed on the damping spring 7 through the spring support seat 6, the sieve body 1 is provided with a floating screen frame 3, and the sieve body 1 and the floating sieve frame 3 are provided with an elastic screen surface 2, floating The screen frame 3 is hung and installed on the lower part of the screen body 1 through the rubber hinge 4, and the floating screen frame 3 can make the polyurethane elastic screen surface 2 swing up and down under the action of the material, so as to speed up the ...

Embodiment 2

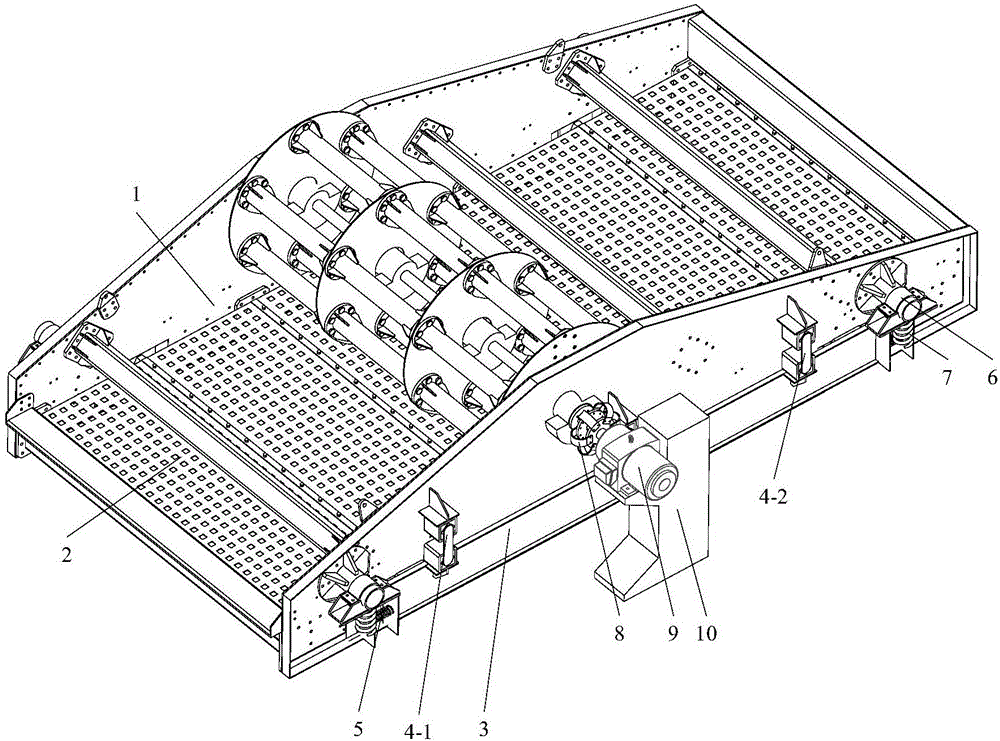

[0052] Embodiment two, figure 2 Shown, it is basically identical with embodiment 1, and identical point is omitted. The difference: the statically indeterminate excitation main beam described is a circular structure superstatic excitation main beam for installing a single set of eccentric mass exciters 11, and a single set of eccentric mass exciters can realize circular vibration excitation .

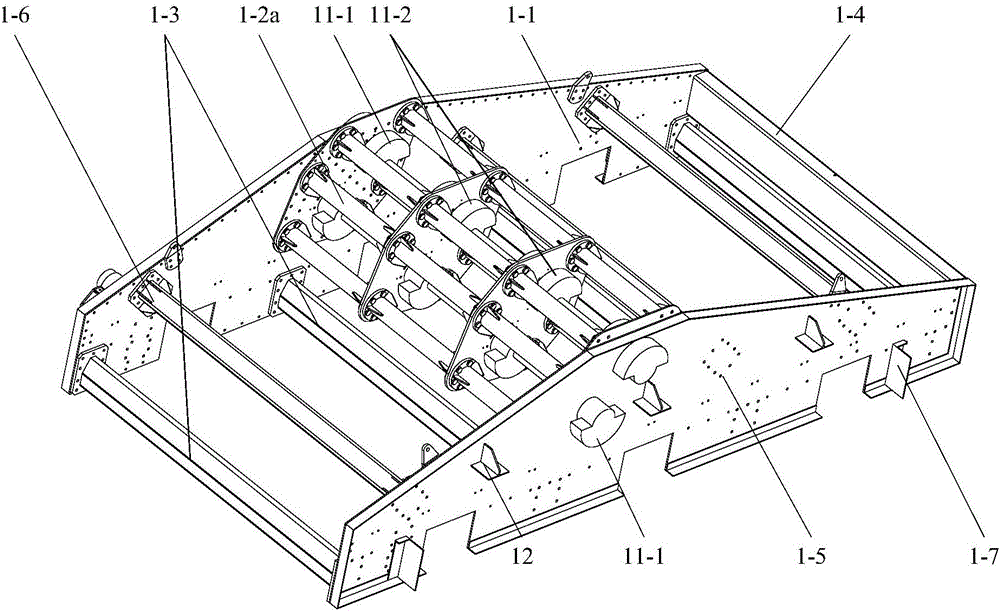

[0053] Figure 4 Figure 6 As shown, the eccentric mass exciter 11 includes a transmission shaft and a plurality of eccentric masses arranged on the transmission shaft, and the plurality of eccentric masses comprise The side plate eccentric block 11-1 on the top and the internal eccentric block 11-2 dispersedly installed on the fixed plate inside the hyperstatically indeterminate excitation main beam, one end of the transmission shaft of the eccentric block vibrator 11 is installed through the coupling 8 The motor 9 on the support 10 is connected; Figure 9 As shown, the staticall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com