Method for monitoring centralized control system data by manufacturing execution system (MES) of coal preparation plant

A technology of centralized control system and coal preparation plant, applied in the field of computer network, can solve the problems of inapplicability, hidden dangers, increased software cost, etc., and achieve the effect of meeting monitoring requirements, convenient integration, and simple installation and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

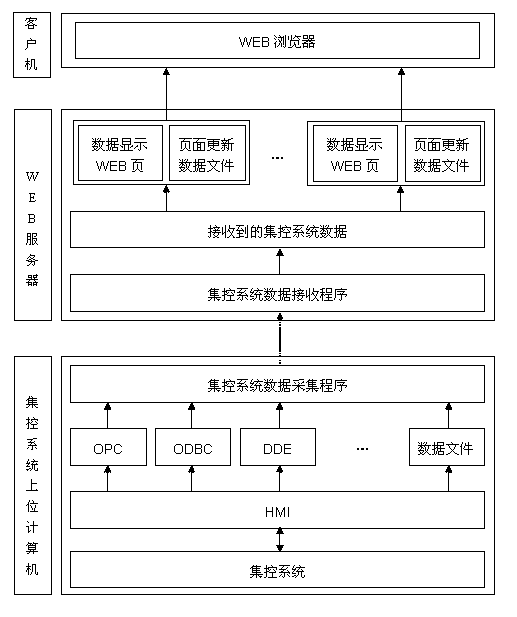

[0017] A method for realizing centralized control system data monitoring by MES of a coal preparation plant, comprising the following steps:

[0018] (1) Connect the monitoring layer network used to monitor the production process in the enterprise's centralized control system with the management network that needs to monitor the data of the centralized control system, and set up firewalls between the networks;

[0019] (2) Set up one or more IIS web servers on the enterprise management network, and deploy data receiving programs on the web servers;

[0020] (3) Install the data acquisition program on one or more upper computers used to monitor the production process in the monitoring layer network, and set the configuration file of the data acquisition program, and specify the destination computer for the data acquisition program to send data in the configuration file address, as well as the namespace to which the collected data belongs and the interval of data collection;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com