Technology for treating coal slime water through secondary flow and settlement filtering centrifuge

A technology of secondary flow and centrifuge, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of affecting production time, large maintenance, and large floor space. problems, to achieve the effect of saving production time, reducing labor intensity, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

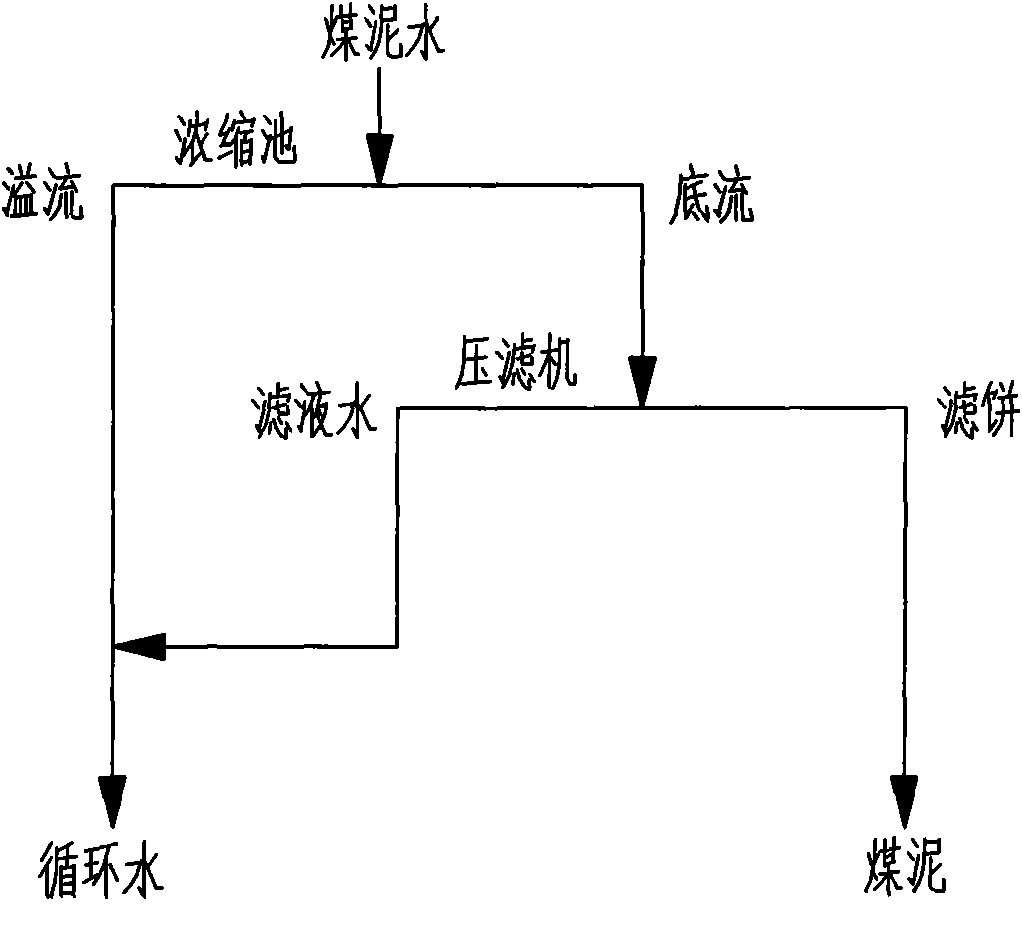

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] This embodiment is a coal preparation plant with a processing capacity of 5.0Mt / a (5 million tons / year).

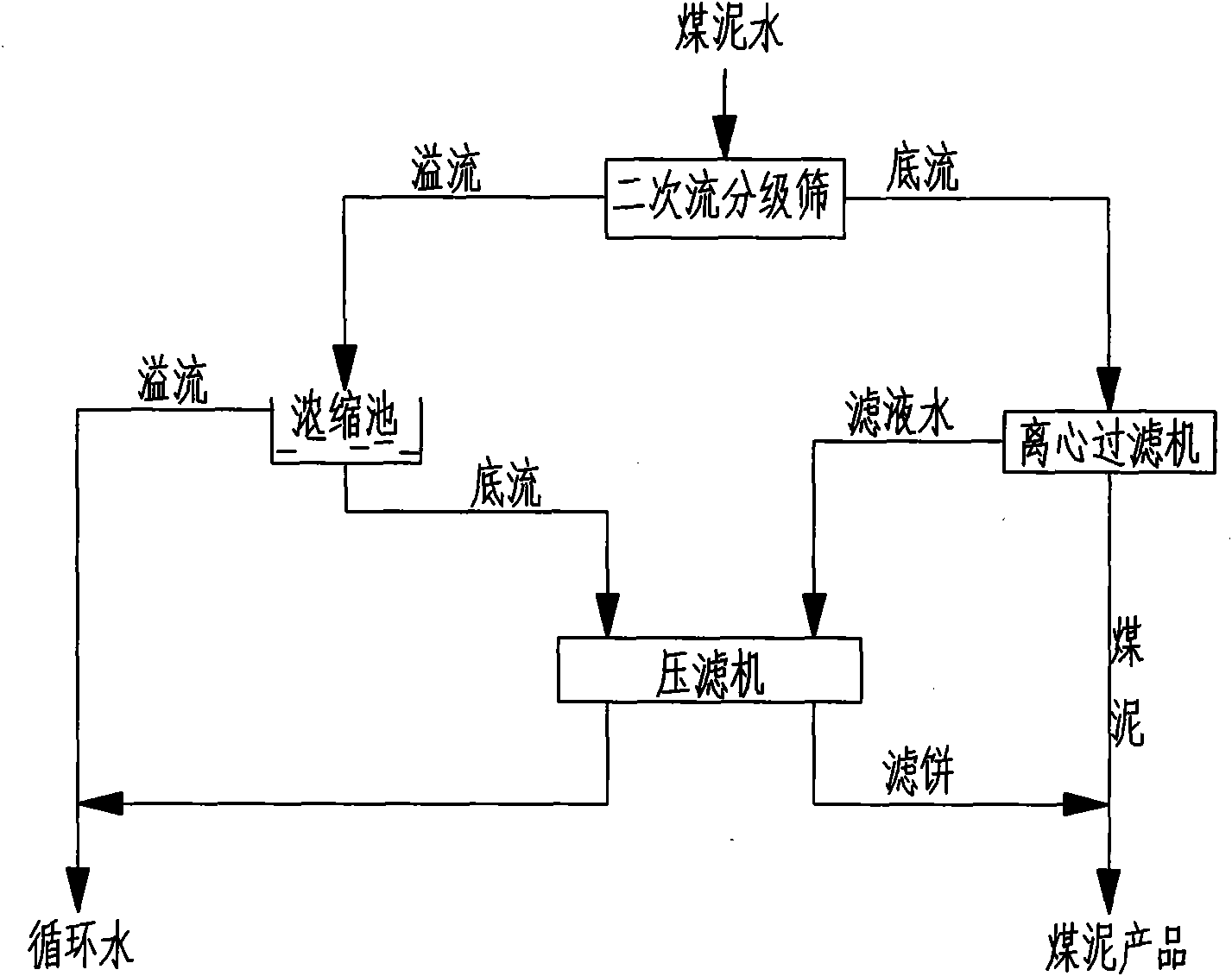

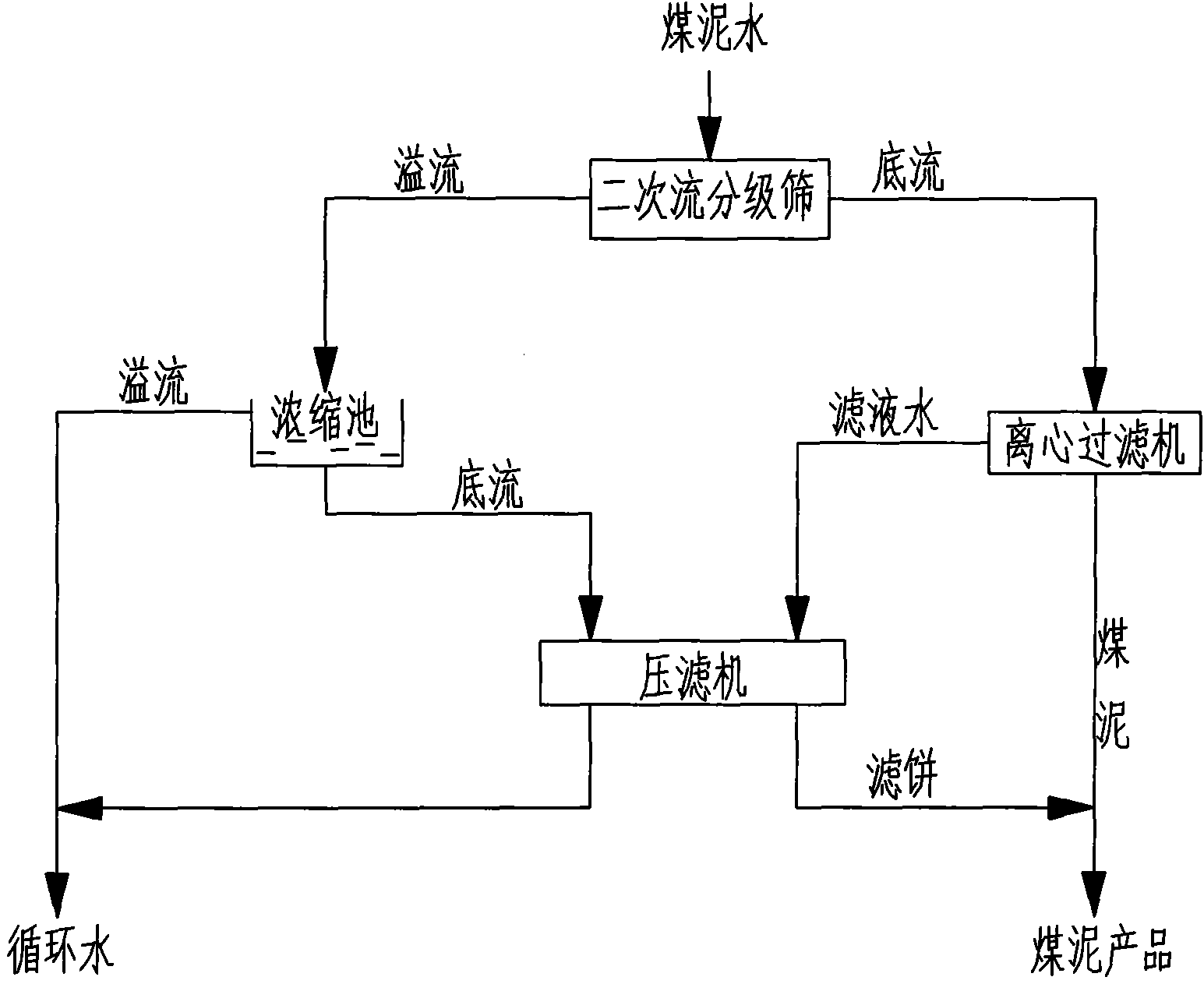

[0015] The equipment includes: two secondary flow grading screens with a diameter of 2.3m, and one with an area of 4m 2 The settling filter centrifuge, a thickener with a diameter of 20m and a floor area of 50m 2 filter press. Two secondary flow grading screens with a diameter of 2.3m are used in parallel; between the secondary flow grading sieve and the concentration tank, between the concentration tank and the filter press, between the secondary flow grading sieve and the sedimentation filter centrifuge, sedimentation filtration The centrifuge and the filter press are respectively connected by pipelines;

[0016] Such as figure 2 As shown, the coal slime water enters the secondary flow grading sieve, and after being classified by the secondary flow grading sieve, the bottom flow, that is, coarse particles, is sent to the filter centrifuge for treatment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com