Tailing mud water treatment method for wet coal preparation plant

A treatment method and technology of a coal preparation plant, applied in water/sludge/sewage treatment, sludge treatment, multi-stage water treatment, etc. Problems such as high moisture content, to achieve the effect of reducing workload, reducing investment costs, and low moisture content in products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

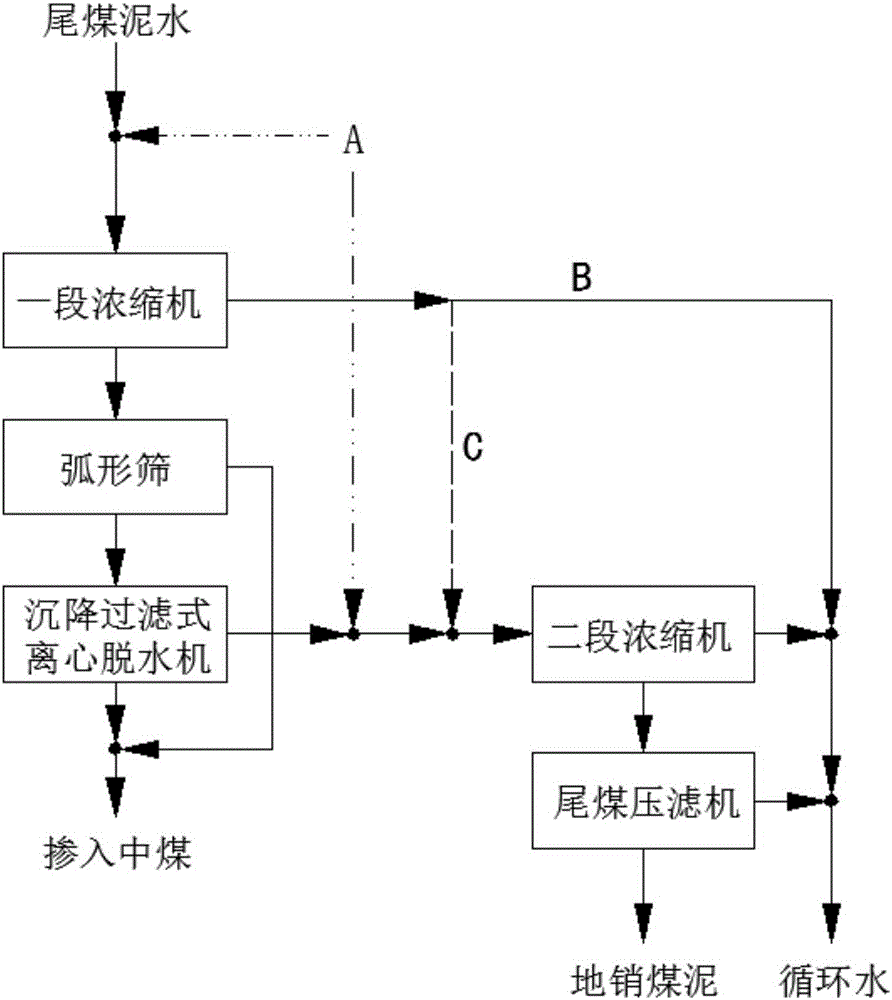

[0017] like figure 1 As shown, it is a schematic flow chart of an embodiment of the present invention, a tailing coal slurry water treatment system of a wet coal preparation plant, which mainly consists of four processes: one-stage concentration, one-stage recovery, second-stage concentration, and second-stage recovery.

[0018] One-stage thickening: The tailing coal slime water of the wet coal preparation plant enters the first-stage thickener for thickening. Obtain the water hardness value of the tailing coal slime, when the water hardness value of the tailing coal slime3 meter, that is, 25.2 German degrees), add a coagulant (as shown in A in the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com