Real-time detecting system and method for vibration screen treatment amount

A technology of real-time detection and vibrating sieve, which is applied to chemical instruments and methods, filtration, solid separation, etc. It can solve the problems of poor accuracy and poor economic effect of manual measurement methods of processing capacity, achieve broad market application prospects, and liberate labor force , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

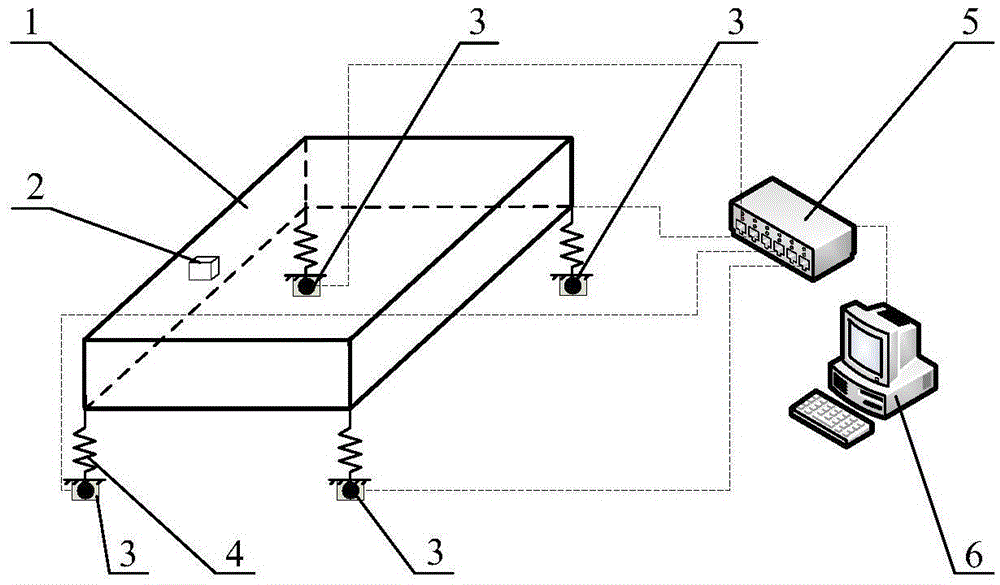

[0029] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

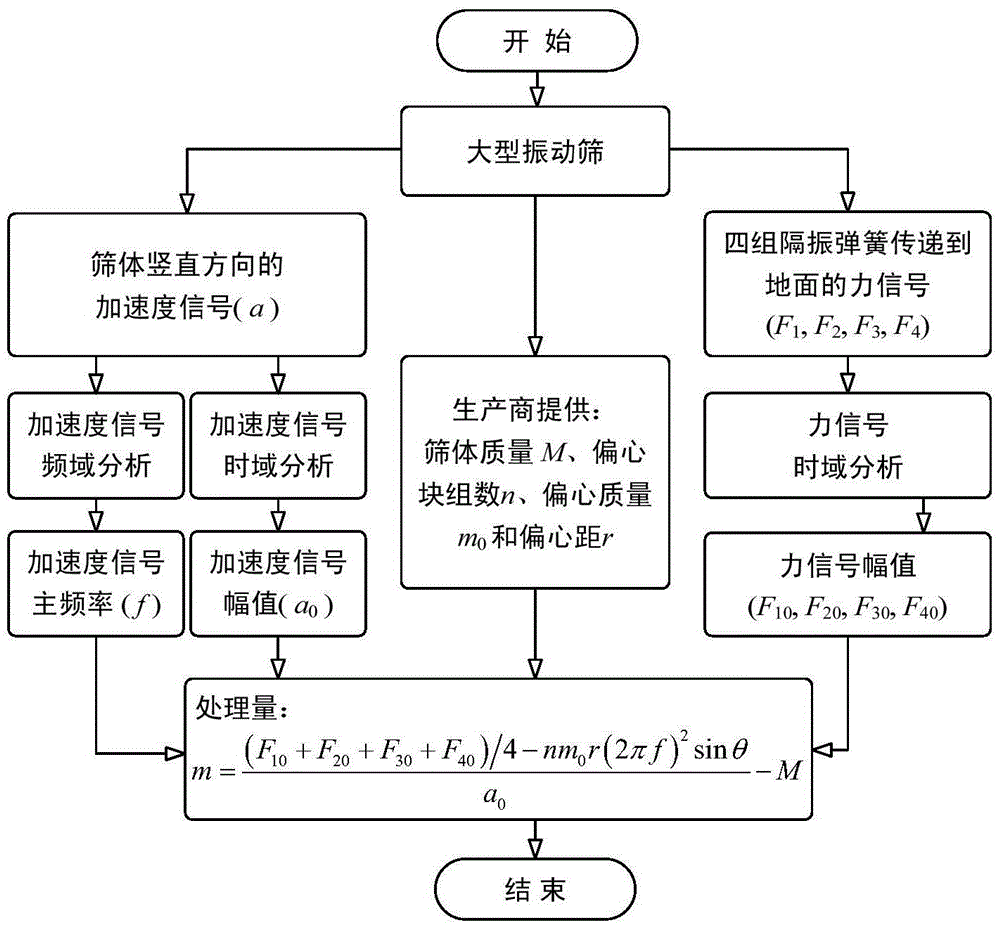

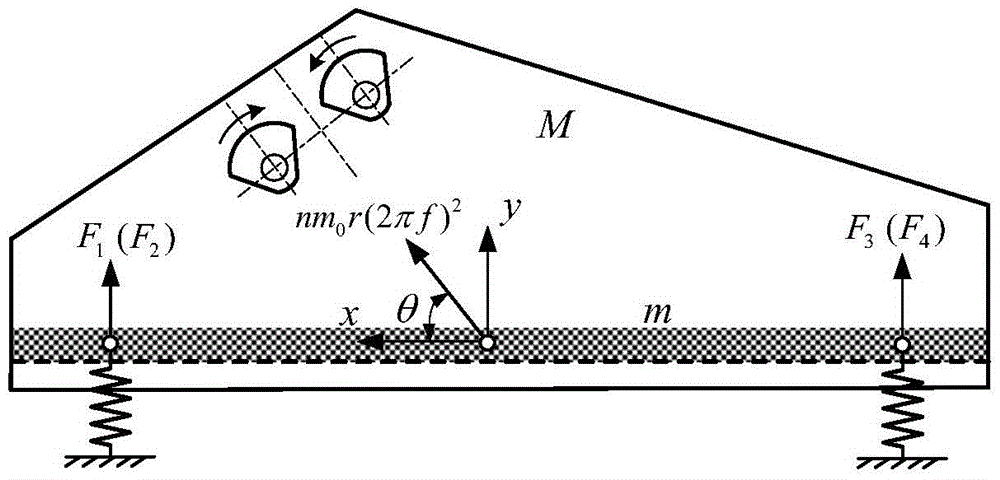

[0030] The invention provides a real-time detection method for the processing capacity of the vibrating screen, such as figure 2 shown, including the following steps:

[0031] Step 1: collect the acceleration time-domain signal a in the vertical direction of the middle part of the vibrating screen, and collect the time-domain signal F of the force in the vertical direction of the vibration isolation spring on the vibrating screen 1 , F 2 , F 3 and F 4 ;

[0032] Utilize the acceleration sensor to detect the acceleration time-domain signal a=a(t) of the vibrating screen in the vertical direction, and use the force sensors at the four corners of the vibrating screen to detect the force on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com