Coal preparation plant thickener and filter press pharmacy adding cooperation control system

A concentrator and filter press technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of low degree of coordination, high worker participation, high consumption of chemicals, etc., to improve the level of automation and production efficiency, economic index reduction, and the effect of reducing chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

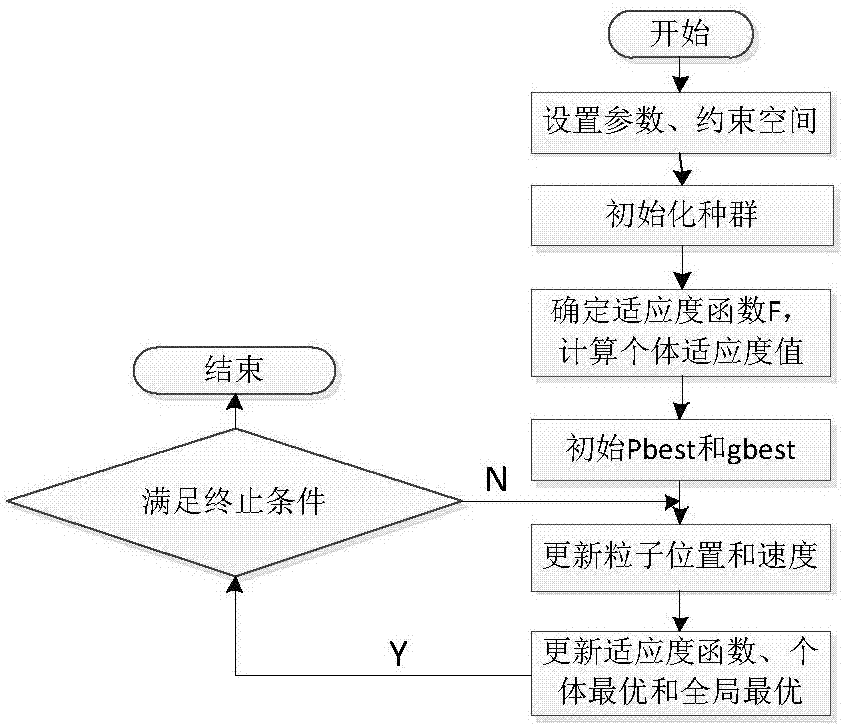

[0047] A method for adding agents to thickeners and filter presses in a coal preparation plant, said method comprising the following steps:

[0048] Data collection: collect N=100 sets of working history data of thickeners and filter presses; data include feed concentration, underflow concentration, feed flow, measured overflow concentration, filter press cycle, and slime moisture.

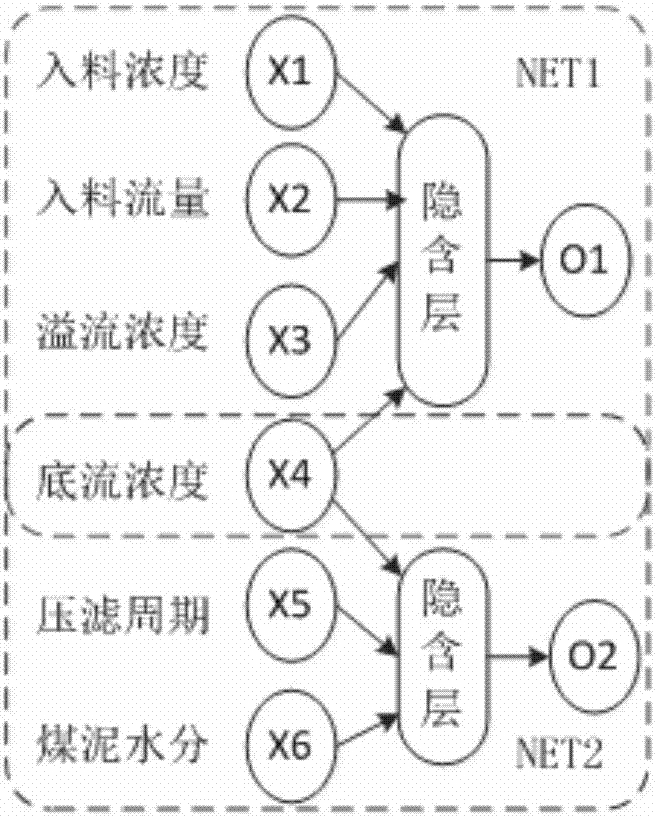

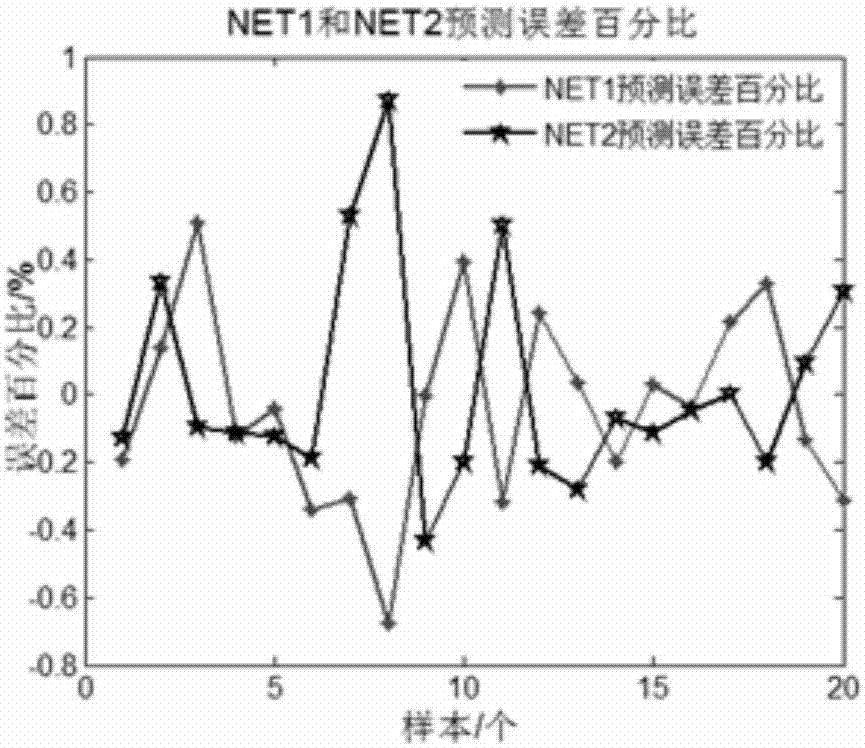

[0049] Construct the prediction model: select 80 sets of data from 100 sets of data and use the training function Newff to establish the prediction models NET1 and NET2 of the dosage of flocculant and coagulant respectively; the input / output relationship of BP network is as follows: figure 1 as shown,

[0050] O1, the amount of flocculant agent added; O2, the amount of flocculant agent added; x 1 , feed concentration; x 2 Feed flow rate; x 3 overflow concentration; x 4 Underflow concentration; x 5 Filtration cycle; x 6 Slime moisture.

[0051] Feed concentration, underflow concentration, fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com