Method for using refined coal magnetic separator tailings for flotation water-spraying foam removal

A clean coal and flotation technology, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increasing the load of coal slime water dehydration process, large investment cost of infrastructure, and increasing the load of flotation machines, etc., to achieve simplification Effect of management and maintenance work, reduction of grading work, reduction of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

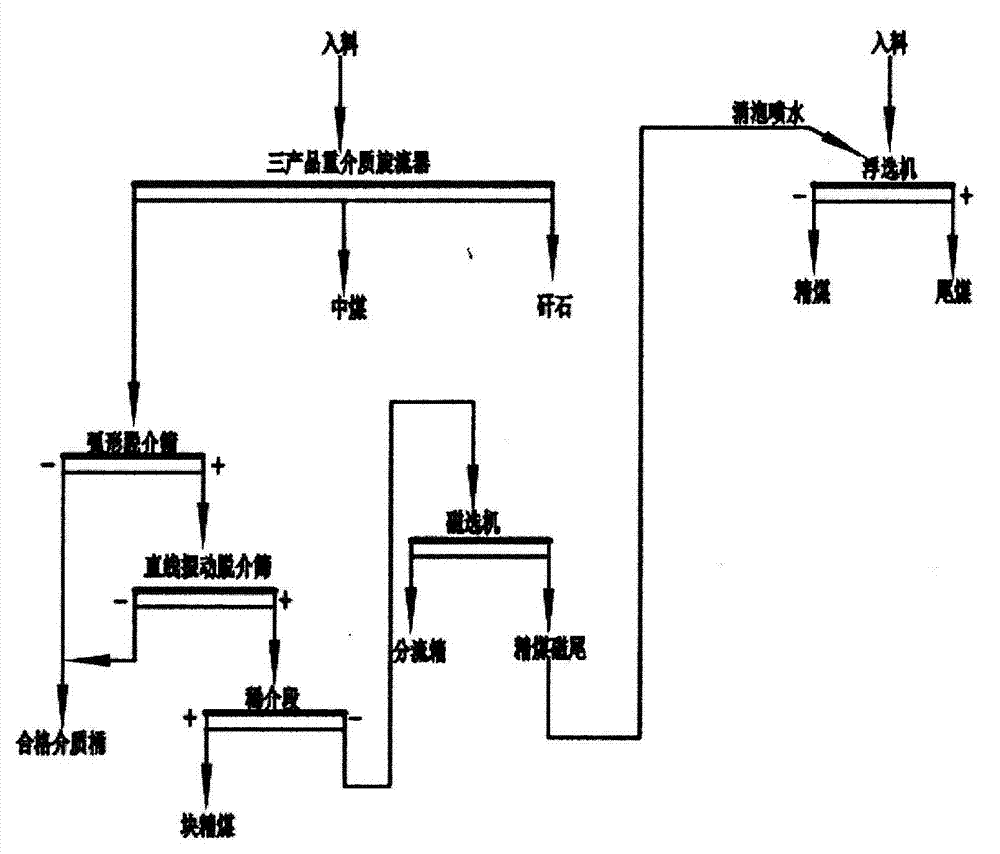

[0031] The present invention will be combined with embodiment below (attachment Figure 4 ) The present invention is described in further detail.

[0032] like Figure 4 As shown, the clean coal magnetotail of the present invention is used as the flotation water injection defoaming method to propose an improved method for the characteristics of a section of overflow clean coal product of the three-product dense medium cyclone, which is a sorting-removal method. Medium—medium recovery—clean coal magnetic tail is used as a flotation defoaming water injection link (see Figure 4 ), making it suitable for the characteristics of the clean coal magnetic tail of the first overflow clean coal product of the three-product dense medium cyclone, especially suitable for the clean coal magnetic tail of the coal preparation plant with a particularly high content of fine-grained materials (-0.5mm) The technical transformation of the tail.

[0033] Technology of the present invention is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com