Method for realizing underground separation of raw coal

A raw coal and sorting technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems such as noise pollution, soil pollution, pollution, etc., and achieve the goal of reducing land occupation, environmental pollution, and investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

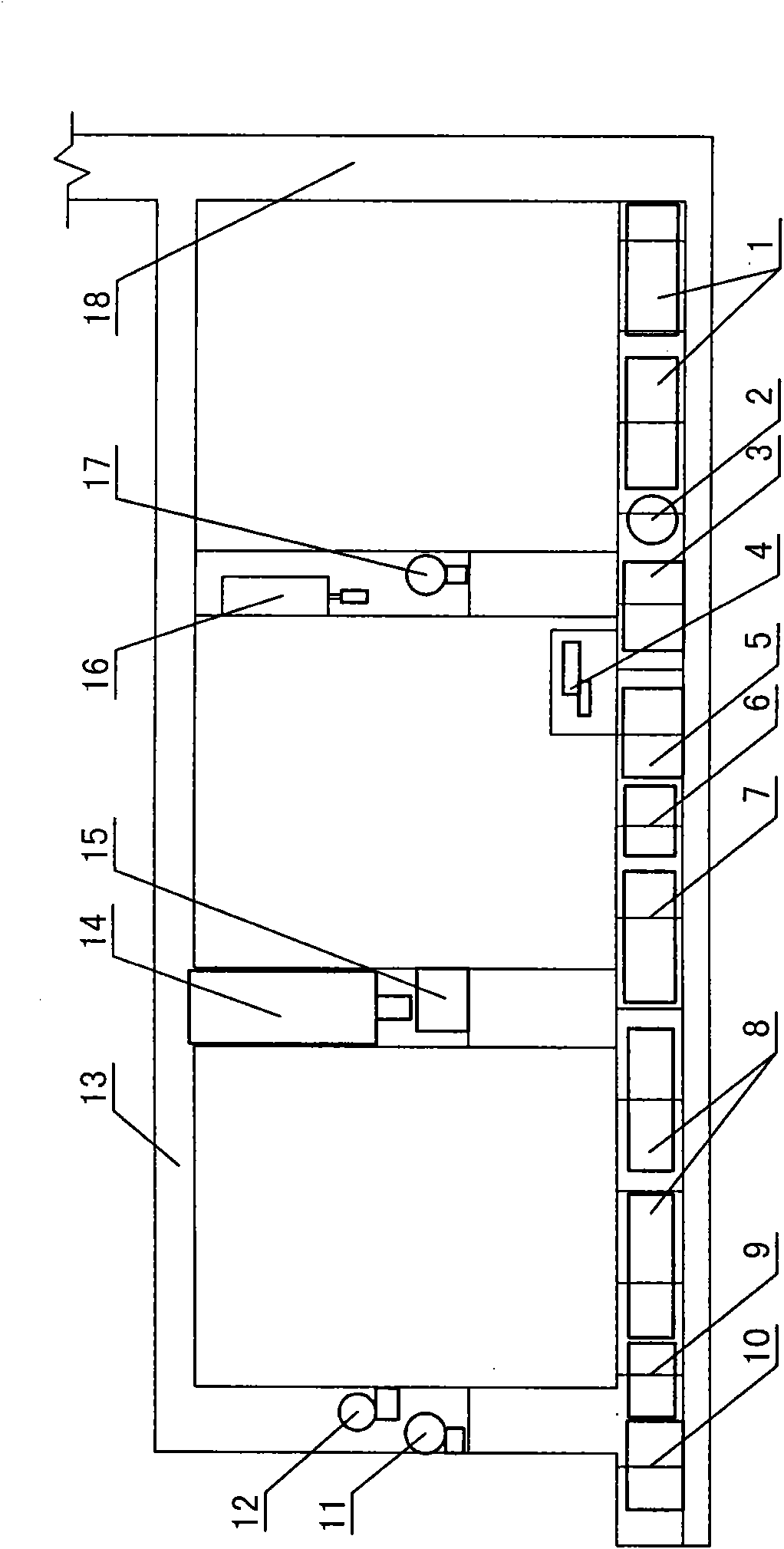

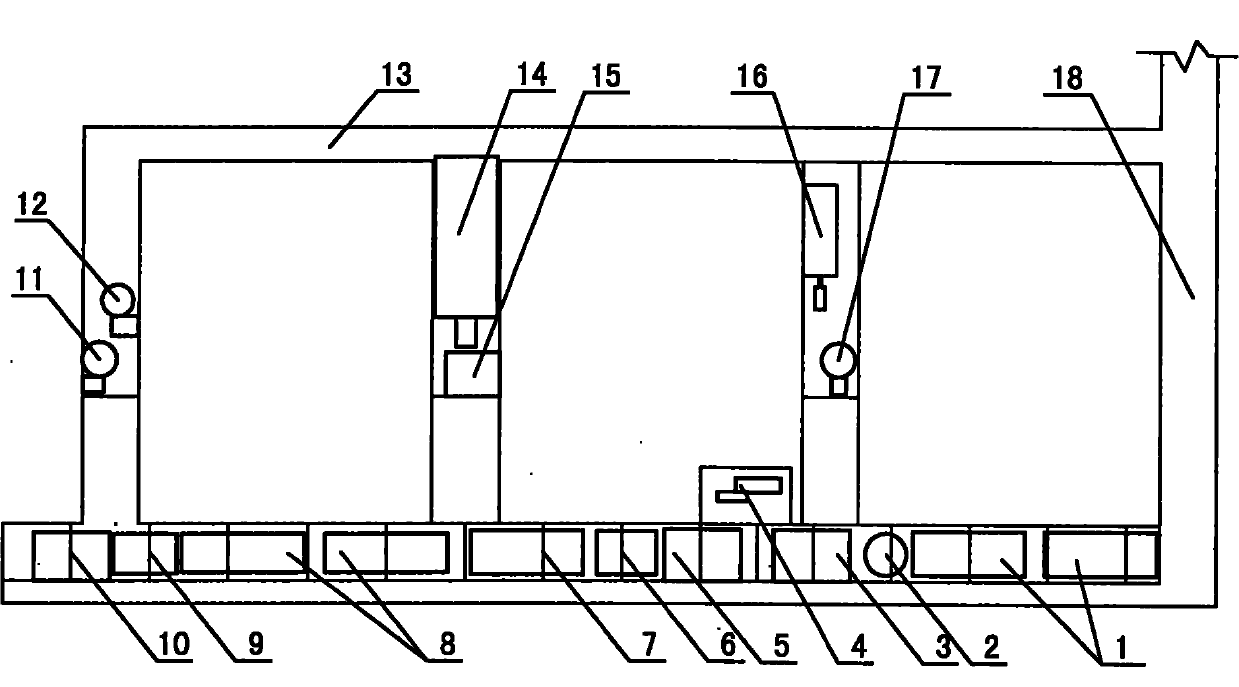

[0025] The present invention will be further described below in conjunction with drawings and embodiments.

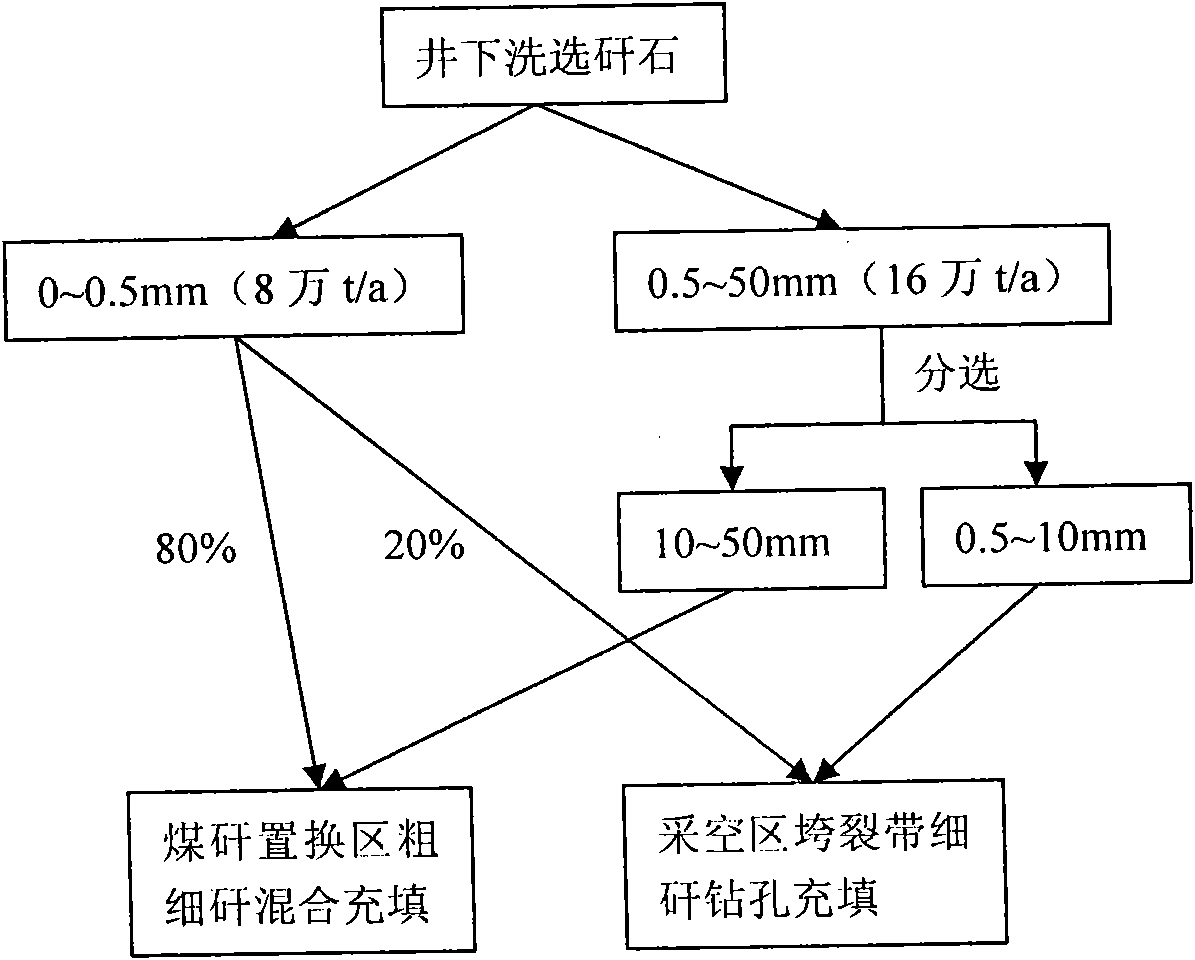

[0026] In this embodiment, the raw coal separation process includes the selected raw coal pre-screening process, product washing process, product dehydration process and coal slime water treatment process. Coal and backfill are combined to realize the integration of mining, selection and filling. The overall process is as follows: the mined raw coal is sent to the coal storage chamber through the belt conveyor, and then transported from the coal storage chamber to the coal preparation chamber for washing. Selection, the selected clean coal products are lifted by the original raw coal hoisting belt into the well and then stored in the ground product warehouse; the washed and selected gangue is backfilled into the goaf. The entire coal preparation process is also completed underground, and the specific implementation method is:

[0027] a. Formulate the underground coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com