Pre-separation process of coal slime flotation

A coal slime and flotation technology, applied in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of excessive increase in flotation system processing capacity, unfavorable comprehensive utilization of resources, and impact on flotation indicators, etc., to achieve high efficiency And the effect of stabilizing the flotation product index, simplifying the flotation environment and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

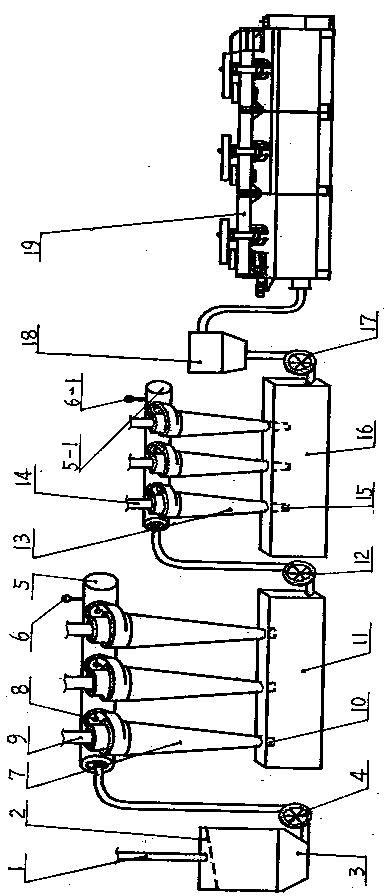

[0009] Examples, see attached figure 1 , The pre-tailing process of flotation slime is to use a hydrocyclone treatment process with a small cone angle before the flotation slime enters the flotation to realize the pre-tailing of the flotation slime. The process is as follows: Fully stir the slime water in the coal slime pool of the coal preparation plant, and after being stirred and mixed evenly, it is classified by the thickening cyclone, the underflow is used as coarse clean coal, and the overflowing slime water is overflowed by the thickening cyclone. The flow feed pipe 1 enters the buffer mixing tank 3. The height of the buffer mixing tank 3 is less than or equal to 1000mm, the cone angle of the cone part of the barrel body is less than or equal to 7 degrees, and the diameter of the overflow feeding pipe is less than or equal to 150mm. The coarse sieve plate 2 installed on the upper side of the mixing tank 3 removes the coarse particles, and the overflow coal slime wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com