Closed-path grading technology suitable for fine pea coal grading

A fine-grained coal and process technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of inconvenient maintenance of equipment, large capital investment, pollution of clean coal, etc., to ensure stability and improve economic benefits , to ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with embodiment (accompanying drawing):

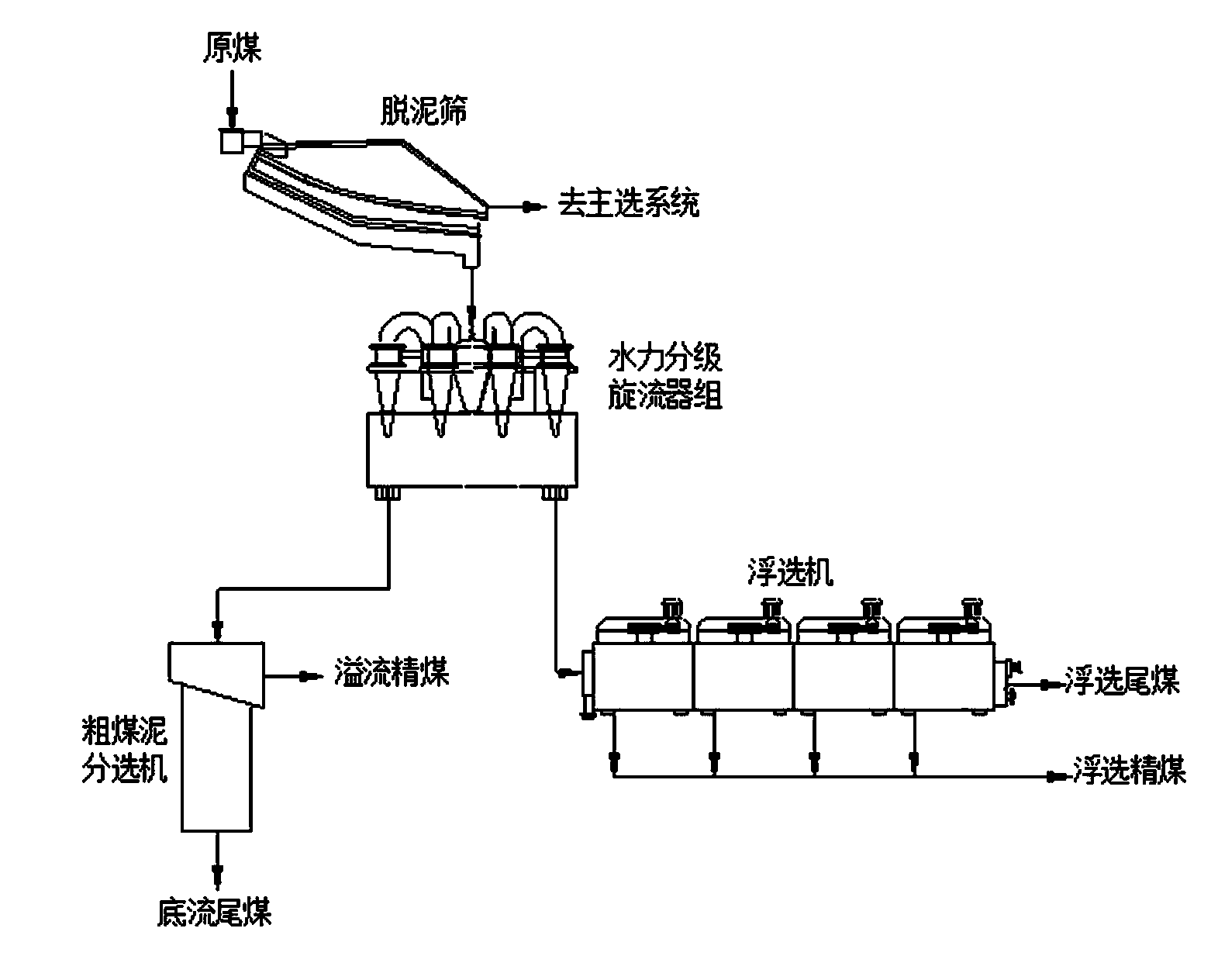

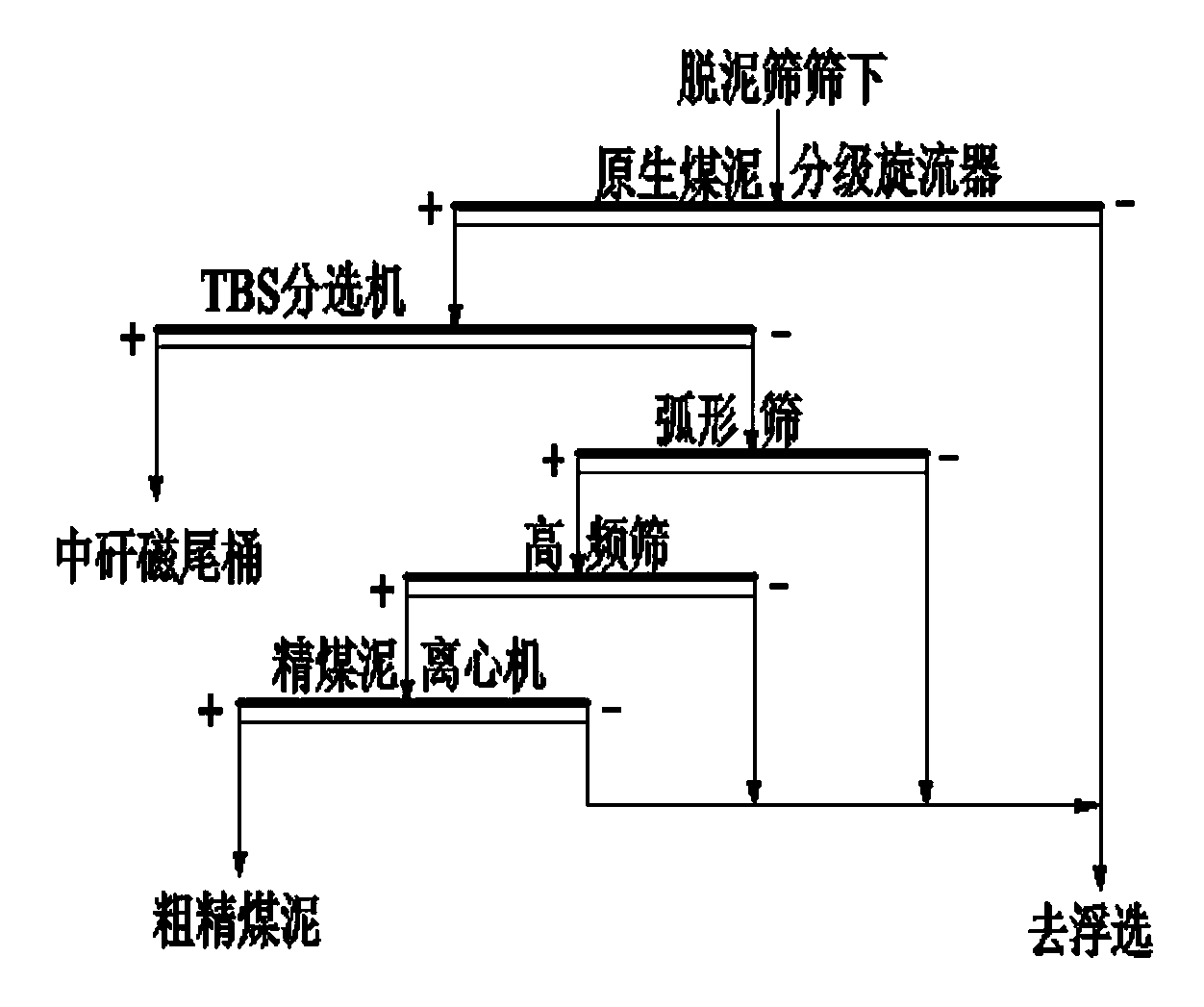

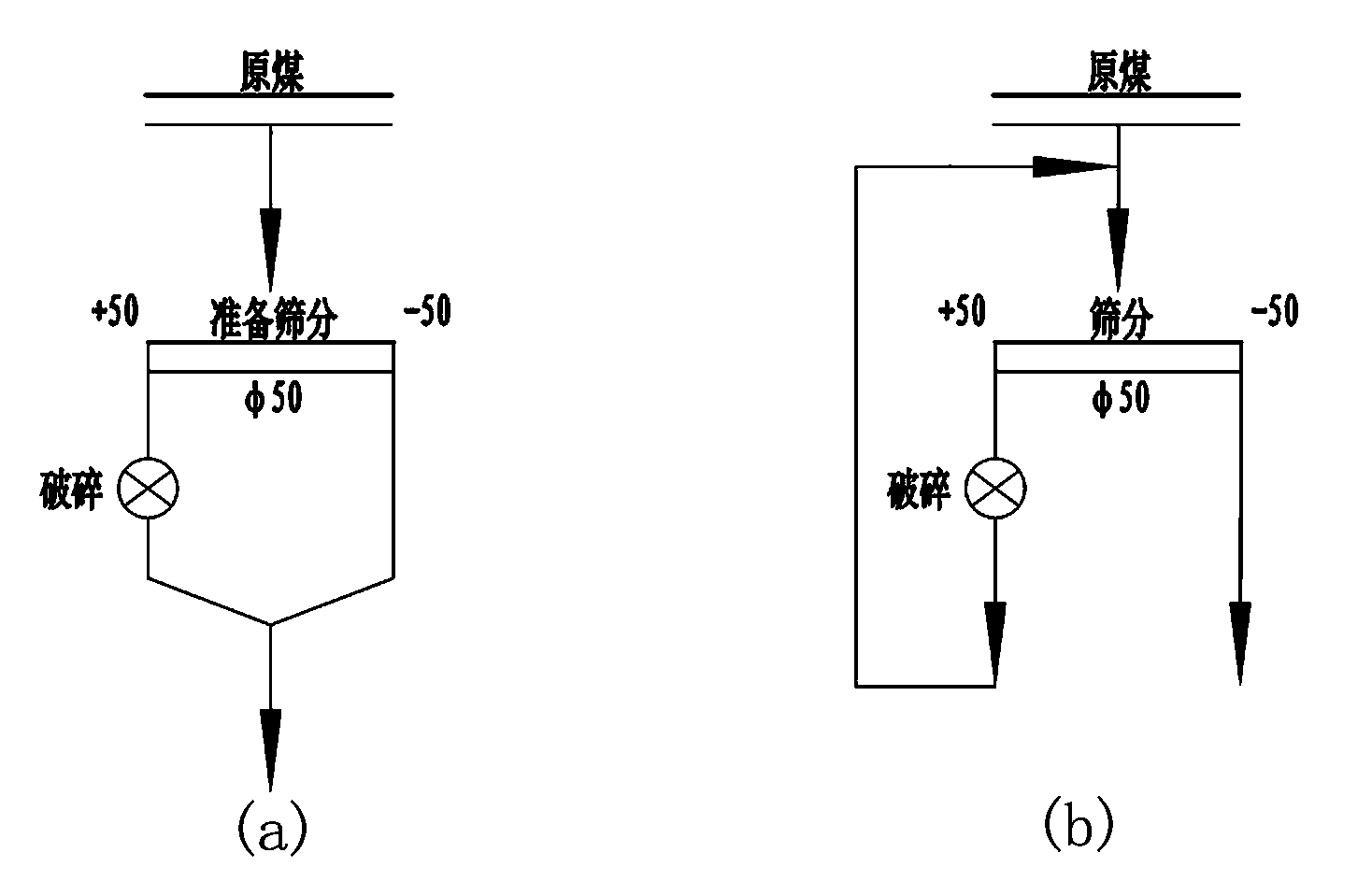

[0031] Such as Figure 5 , 6 As shown, a closed-circuit classification process suitable for fine-grained coal classification of the present invention is aimed at the characteristics of the overflow product and underflow product of the hydraulic classification cyclone, and proposes a closed-circuit classification process for fine-grained coal, that is, for the traditional fine-grained coal The granular coal hydroclassification cyclone process is improved to make it suitable for the characteristics of the hydroclassification cyclone product, especially suitable for the technical transformation of the coal preparation plant with a particularly high content of fine material (<1mm) to its fine coal classification process .

[0032] In the closed-circuit classification process suitable for fine-grained coal classification in the present invention, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com