Flotation feed pretreatment device

A pretreatment device and flotation technology, applied in solid separation and other directions, can solve the problems of not fully applicable to coal preparation plants, high production cost, single function, etc. Effect of Coal Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

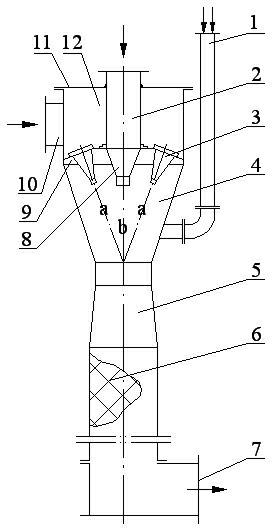

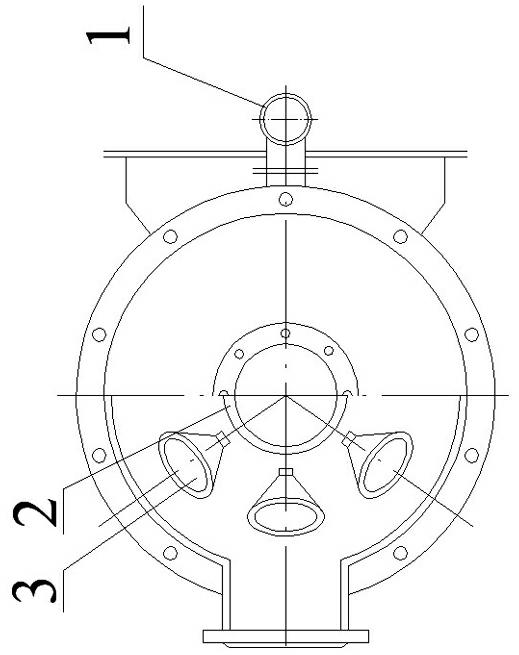

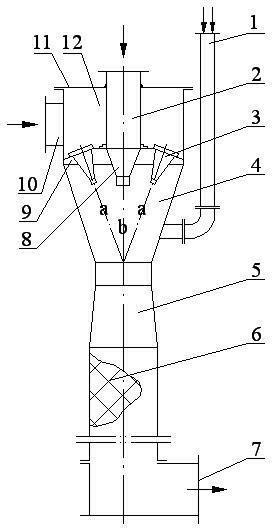

[0014] See attached Figure 1-2 , The flotation feed pretreatment device disclosed in the present invention integrates concentration dilution, premineralization, flotation agent emulsification and mixing of flotation feed, dilution water, flotation agent emulsion, and air bubbles. The pretreatment device includes a feed chamber 12, a mixing chamber 4, a throat 5 and a mixing mechanism 6, and also includes a dilution water pipe 2, a suction pipe 1 and a multi-nozzle ejector, and the flotation feed pipe 10 communicates with the feed chamber 12 . The multi-nozzle ejector is arranged between the feeding chamber 12 and the mixing chamber 4 through the connecting seat 9, and the multi-nozzle ejector includes a plurality of feeding nozzles 3 evenly arranged on the circumference of the connecting seat 9 and a center of the connecting seat 9 Dilution water nozzle 8. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com