Agent and method for flotation separation of chalcopyrite-iron sulfide minerals

A separation method and flotation reagent technology, applied in flotation, solid separation and other directions, can solve the problems of weak selectivity and high reagent cost, and achieve the effect of low raw material cost, obvious environmental protection advantages, and improved sorting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This case uses combined collectors for chalcopyrite or pyrite flotation:

[0045] The mixed collector includes collector 1: collector 2, and the molar ratio of the two is 1:0.2:

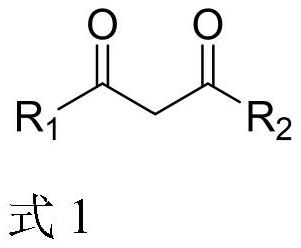

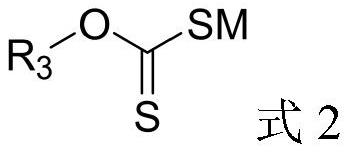

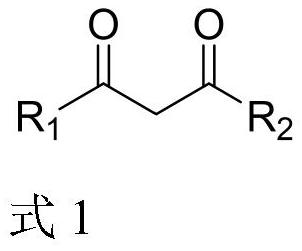

[0046] Collector 1:

[0047] Collector 2:

[0048] Chalcopyrite or pyrite flotation, the specific steps are: add 2g of chalcopyrite or pyrite single mineral with a particle size of -74+38μm and 40mL of deionized water into the flotation tank, and stir at 1700r / min Add the above mixed collector after 1min, the amount of mixed collector is 8×10 -5 mol / L, continue to stir for 3 minutes, then adjust the pH of the pulp to 9.0, then add 20 g / t foaming agent of a mixture of sodium lauryl sulfate and ethanol with a molar ratio of 1:0.2, and continue to stir for 2 minutes to carry out aerated flotation. 3min. Finally, the concentrated ore and tailings after flotation were weighed dry respectively, and the calculated chalcopyrite and pyrite recovery rates were 92.35% and 15.13% respectively, and...

Embodiment 2

[0050] The artificial mixed ore flotation of chalcopyrite and pyrite, the specific steps are: add 2g of artificial mixed ore (mass ratio 1:1) and 40mL deionized water into the flotation cell with a particle size of -74+38μm, Add the mixed collector described in the above-mentioned embodiment 1 after stirring for 1min under the rotating speed of / min, and the consumption of the mixed collector is 8×10 -5 mol / L, continue to stir for 3 minutes, then adjust the pH of the pulp to 9.0, then add 20 g / t foaming agent of a mixture of sodium lauryl sulfate and ethanol with a molar ratio of 1:0.2, and continue to stir for 2 minutes to carry out aerated flotation. 3min. Finally, the concentrated ore and tailings after flotation were weighed and tested for Cu grade, and the calculated Cu grade and recovery rate in the chalcopyrite concentrate were 27.35% and 90.18%, respectively. The results show that the mixed collector can better realize the selective separation of chalcopyrite and pyri...

Embodiment 3

[0052] In this case, combined collectors are used for the flotation of chalcopyrite-pyrite type copper-sulfur ore:

[0053] The mixed collector includes collector 1: collector 2, and the molar ratio of the two is 1:0.2:

[0054] Collector 1:

[0055] Collector 2:

[0056] A low-grade copper mine in Jiangxi, the mine is a chalcopyrite-pyrite type copper-sulfur ore, the Cu grade is 0.45%, mainly chalcopyrite. The grinding fineness of the copper ore is controlled at -0.074mm, the dry ore content accounts for 70% of the total dry ore, the slurry concentration is controlled at 40%, and then 80g / t of mixed collector is added, stirred for 3 minutes and then washed with sodium carbonate Adjust the pH of the pulp to 10, then add 30g / t foaming agent of a mixture of sodium lauryl sulfate and ethanol with a molar ratio of 1:0.3, and carry out one rough, one sweep and two fine at room temperature (selected as blank concentrate, swept The amount of collector used is 20g / t) flotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com