Spraying device capable of automatically adjusting yield

An automatic adjustment and spraying device technology, applied in spraying devices, liquid spraying devices, safety devices, etc., can solve problems affecting coal mine transportation and coal preparation operations, unable to adjust water spray volume, unable to spray water to reduce dust, etc., to achieve spray dust reduction Good effect, convenient installation and movement, and long maintenance period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

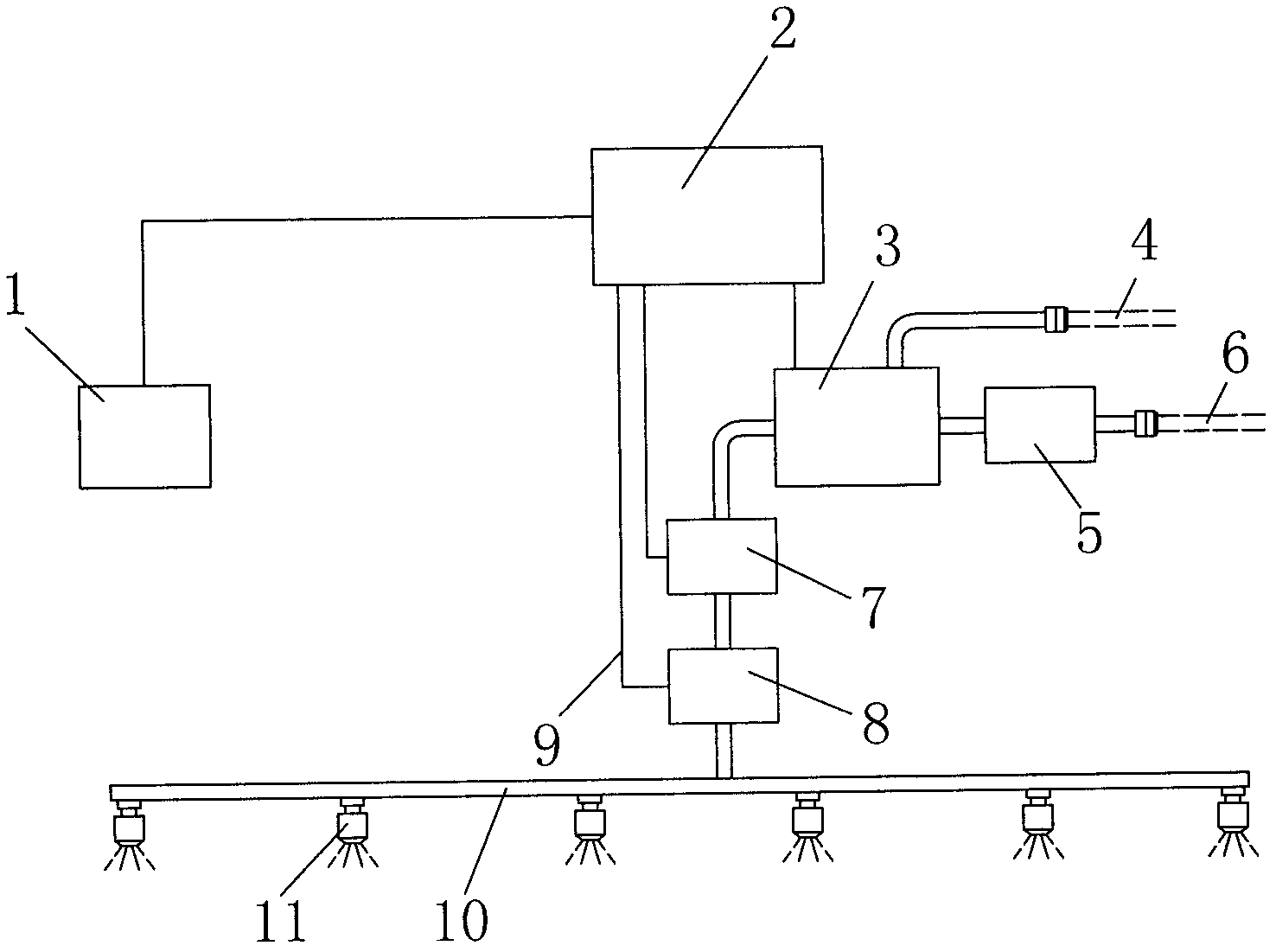

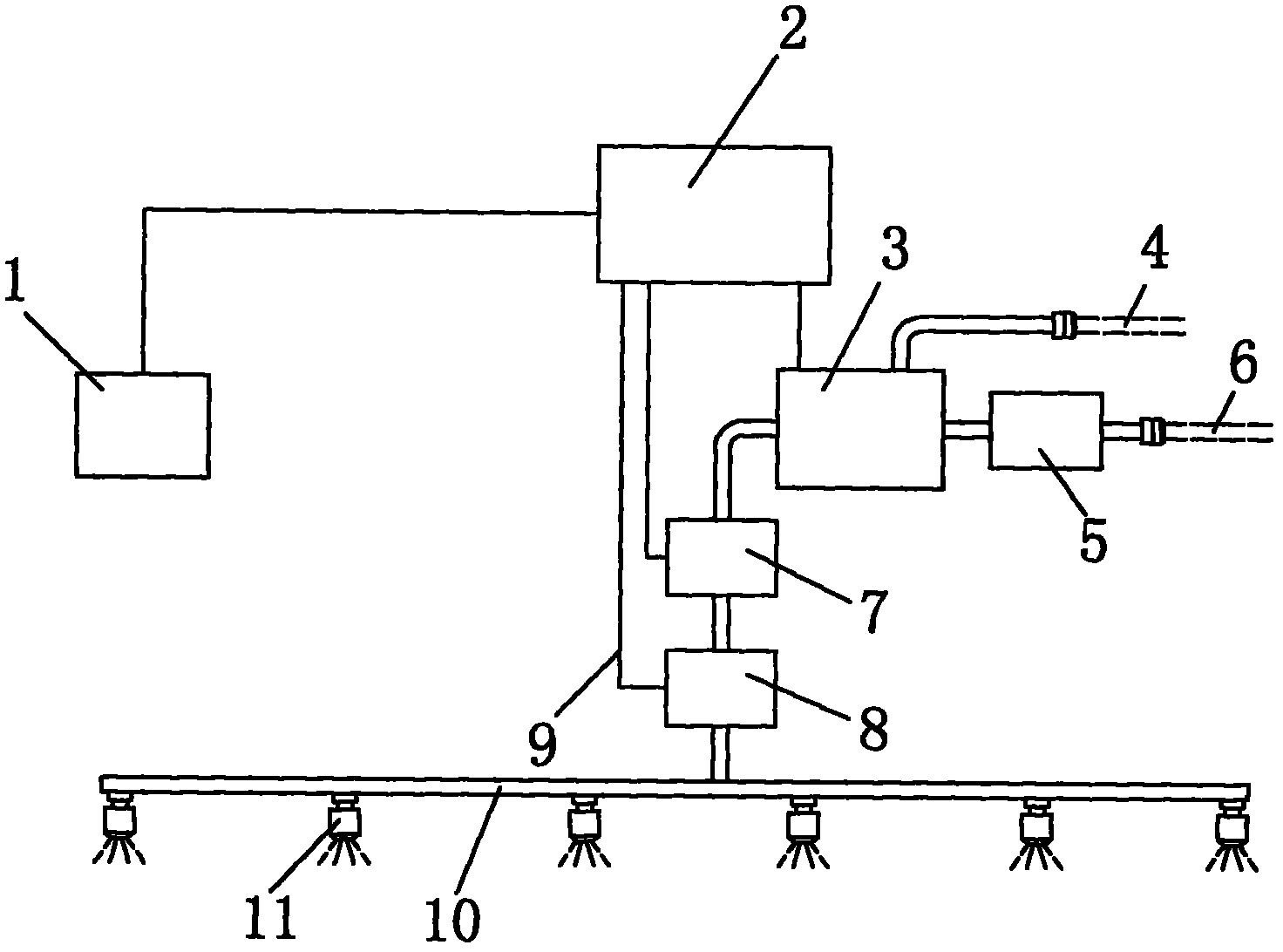

[0014] Such as figure 1 As shown, a mass-produced automatic adjustment spray device is composed of a production measurement sensor 1, a controller 2, a pneumatic diaphragm pump 3, a filter 5, a solenoid valve 7, a flow control valve 8, a pipeline 10 and a nozzle 11. Among them, the output measurement sensor 1 is installed in the idler of the belt conveyor, the controller is connected with the output measurement sensor 1, the pneumatic diaphragm pump 3, the solenoid valve 7, and the flow control valve 8 through the electric wire 9, and the water inlet of the filter 5 is connected with the water source 6-phase connection, its water outlet is connected to the pneumatic diaphragm pump 3, the air inlet of the pneumatic diaphragm pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com