Large-fall vibration absorption and noise reduction buffering device

A buffer device, a technology with large drop, applied in transportation, packaging, chute and other directions, can solve the problems of impact damage to the chute and subsequent equipment, difficult maintenance, low reliability of the production system, etc., to save material costs and maintenance costs, The effect of reducing the labor intensity of employees and improving the labor environment of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

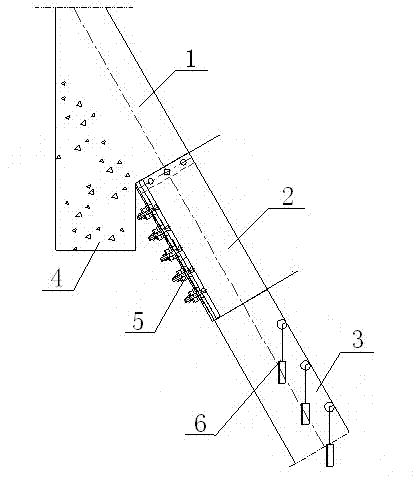

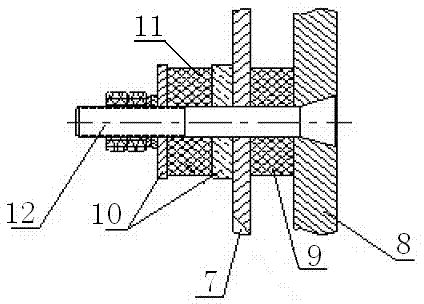

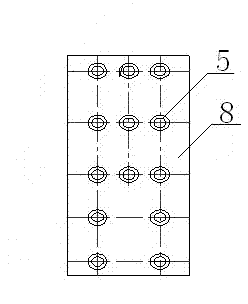

[0024] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes an upper chute section 1, a middle chute section 2 and a lower chute section 3 connected in sequence, the upper chute section 1 is provided with a buffer box 4, the bottom of the middle chute section 2 is provided with several buffer structures 5, and the end of the lower chute section 3 is suspended There are several ring hammers 6 . The buffer structure 5 is distributed at the bottom of the middle chute section 2, including the middle motherboard 7 at the bottom of the middle chute section 2, the inner side of the middle motherboard 7 is provided with a lining board 8, and a polyurethane buffer pad is added between the middle motherboard 7 and the lining board 8 9. Two baffles 10 are installed on the outer side of the middle motherboard 7 , and a polyurethane shock-absorbing pad 11 is arranged between the two baffles 10 . The middle motherboard 7, liner 8, polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com