Novel material for socks

A new material and sock technology, applied in the field of chemical fiber equipment, can solve the problems of large impact force, large buffer stroke, strong vibration, etc., to achieve the effect of large impact force and large buffer stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

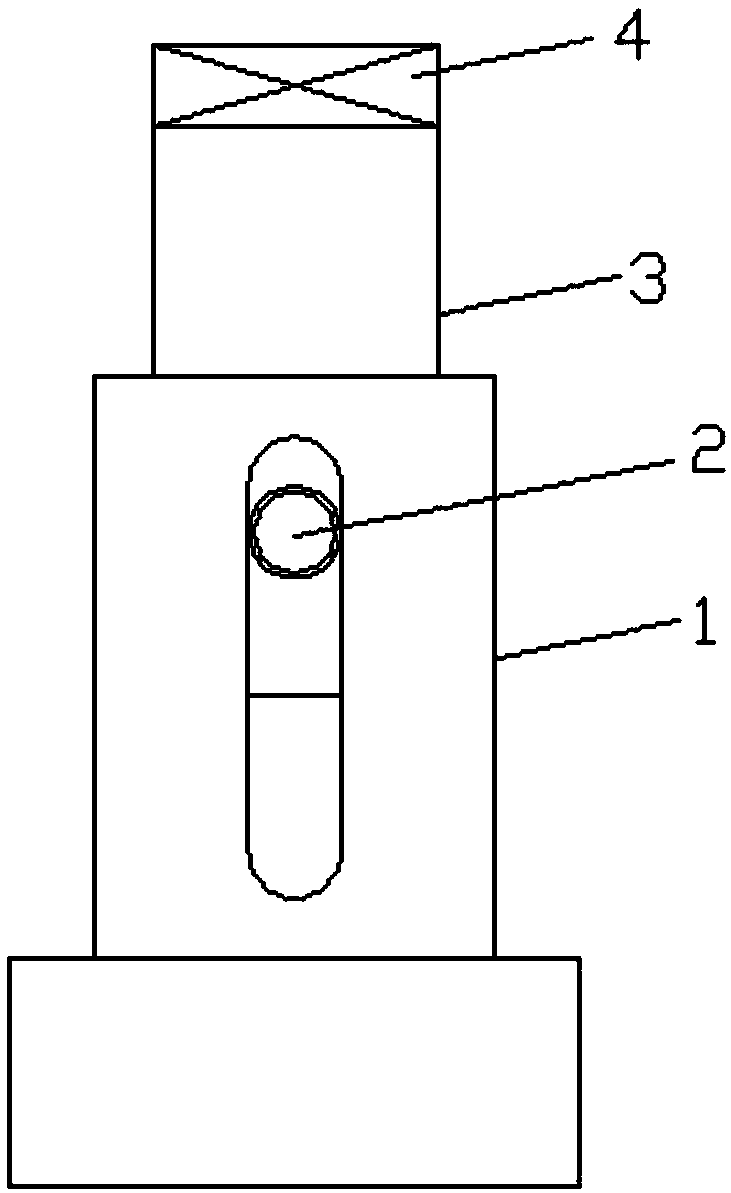

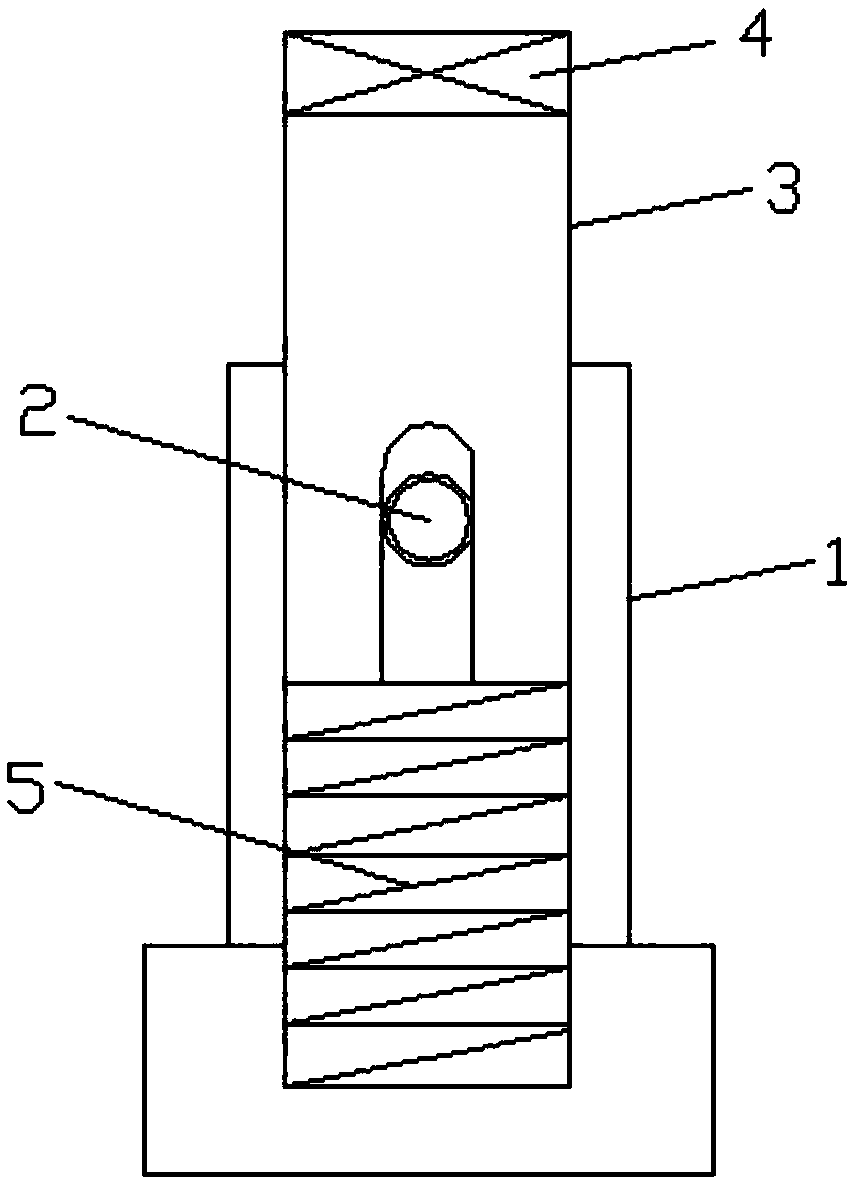

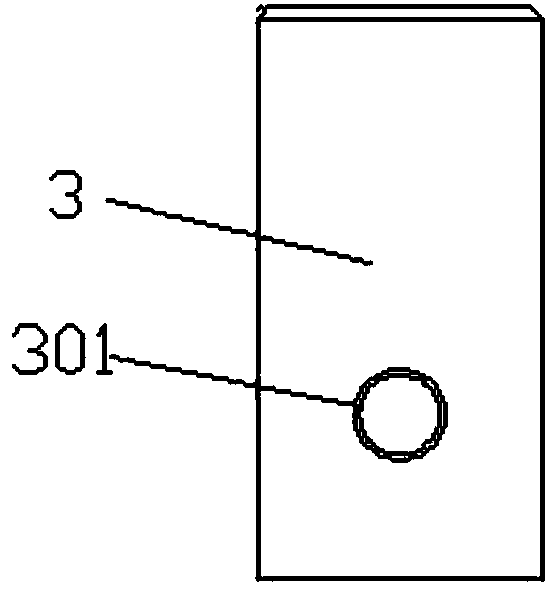

[0014] The technical solution of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0015] Such as Figure 1 to Figure 5 Shown, a kind of new material of socks comprises buffer seat 1, positioning bar 2, buffer bar 3, elastic block 4, spring 5, and described buffer seat 1 is provided with buffer hole 101, and the hole wall of described buffer hole 101 is provided with A positioning groove 102 of an opening, a spring 5 is established in the buffer hole 101, the buffer rod 3 is packed in the buffer hole 101, a screw hole 301 is set on the circumference of the buffer rod 3, and the positioning rod 2 passes through the positioning groove 102 and the head The external thread 201 is screwed to the screw hole 301. The invention has sufficient elasticity, large buffer stroke, and automatic elastic reset, which solves the problems of the previous integrated elastic rod-high impact force, strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com