Super-strong and super-toughened ceramic cutter and manufacturing method thereof

A kind of technology of ceramic cutting tool and manufacturing method, which is applied in the direction of cutting tools used in lathes, manufacturing tools, accessories of tool holders, etc., can solve the problems of easy cracks, insufficient fracture toughness, poor bending strength and thermal shock resistance, etc., Achieve the effects of small friction, high production efficiency, safe and environmentally friendly production materials

Active Publication Date: 2011-01-05

深圳市宏通新材料有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Compared with other tool materials, the most obvious disadvantages of ceramic tools are insufficient fracture toughness, poor bending strength and thermal shock resistance, and cracks are prone to occur when the cutting temperature changes significantly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Login to View More

Abstract

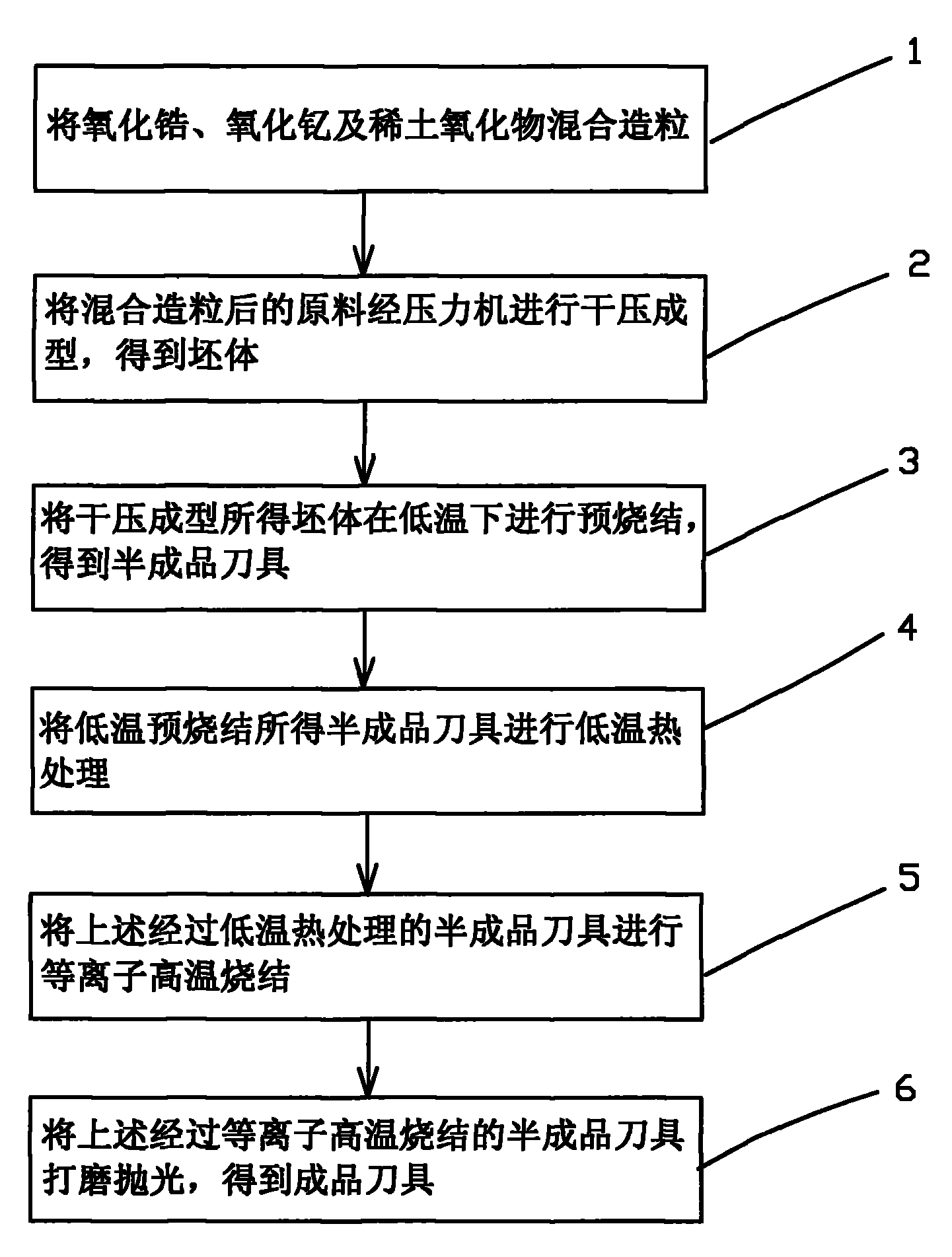

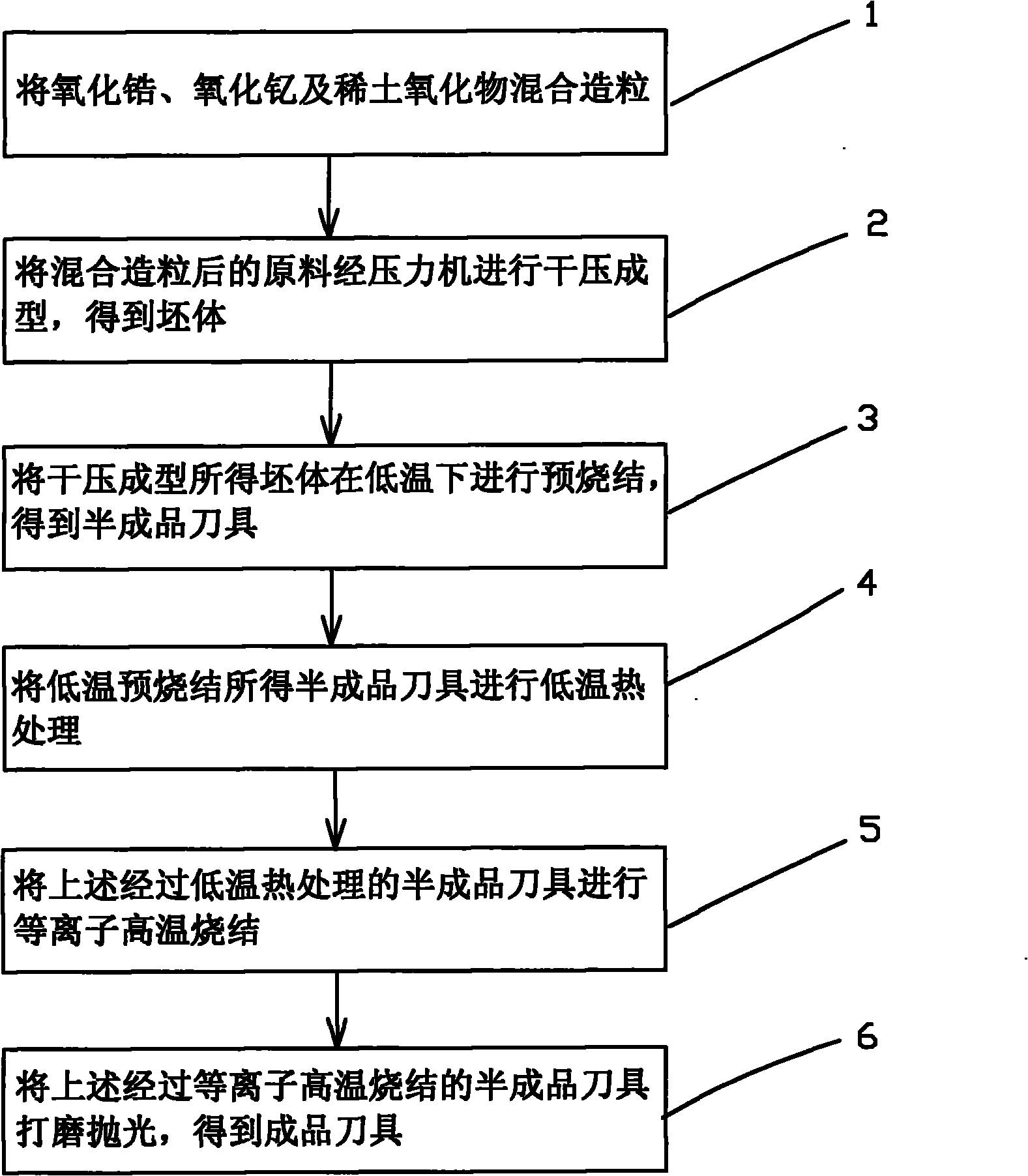

The invention relates to a super-strong and super-toughened ceramic cutter and a manufacturing method thereof. The ceramic cutter comprises the following components in portion by weight: 89 to 95 portions of zirconia, 2 to 8 portions of yttria, and 2 to 4 portions of rare earth oxide. The manufacturing method for the ceramic cutter comprises the following: step 1, mixing and granulating the zirconia, the yttria and the rare earth oxide; step 2, dry-pressing and molding the mixed and granulated raw materials by a press to obtain a blank; step 3, pre-sintering the blank obtained by the dry-pressing and molding at the low temperature to obtain a semi-finished cutter; step 4, thermally treating the semi-finished cutter obtained by the low-temperature pre-sintering at the low temperature; step5, carrying out plasma high-temperature sintering for the semi-finished cutter which is thermally treated at the low temperature; and step 6, grinding and polishing the semi-finished cutter which is subjected to the plasma high-temperature sintering to obtain a finished cutter. The ceramic cutter has high hardness and good abrasion resistance, and has the remarkable advantages on thermal stability, heat conduction, corrosion resistance, oxidation resistance, high-temperature hardness, high-temperature strength, and the like. The method has the advantages of simple process and high production efficiency, and is favorable for mass mechanized production.

Description

Super-strong and super-tough ceramic cutter and manufacturing method thereof technical field The invention relates to a cutting tool and a manufacturing method thereof, in particular to a super-strong and super-tough ceramic cutting tool and a manufacturing method thereof. Background technique Cutting is the most basic and reliable processing method in mechanical processing, and the performance of cutting tools is one of the decisive factors affecting the efficiency, precision and surface quality of cutting processing. Tool materials have gone through several development stages such as carbon tool steel, high-speed steel, cemented carbide, ceramics and superhard materials. According to CIRP data, due to the improvement of tool materials, the allowable cutting speed during processing doubles almost every 10 years. In the modern processing process, the most effective way to improve processing efficiency is still to adopt high-speed cutting processing technology. Due to its...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23B27/00C04B35/48

Inventor 邓湘凌

Owner 深圳市宏通新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com