Highway pavement joint cutting device with automatic adjusting function for monitoring line installation

A technology of automatic adjustment and angle adjustment device, applied in the direction of road, road, road repair, etc., can solve the problems of frequent adjustment, poor control of adjustment height, different depths of embedded joints, etc., to achieve the effect of easy and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the features, technical means, and specific goals and functions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

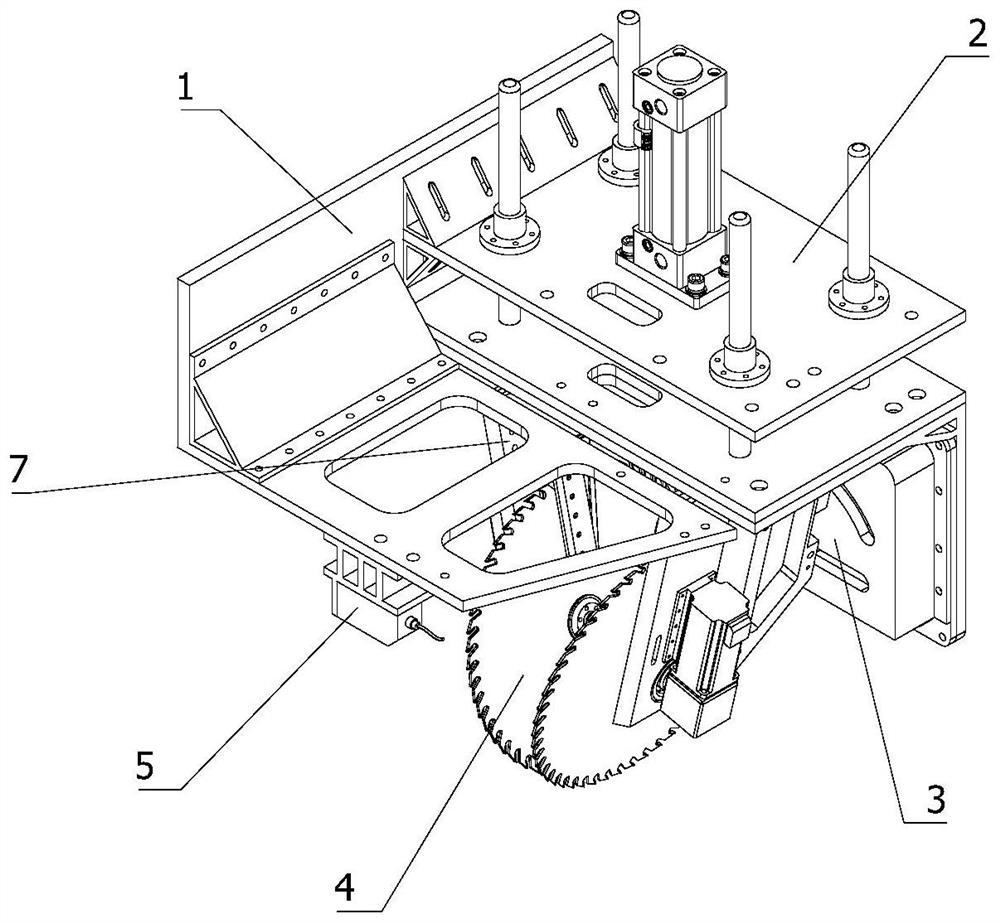

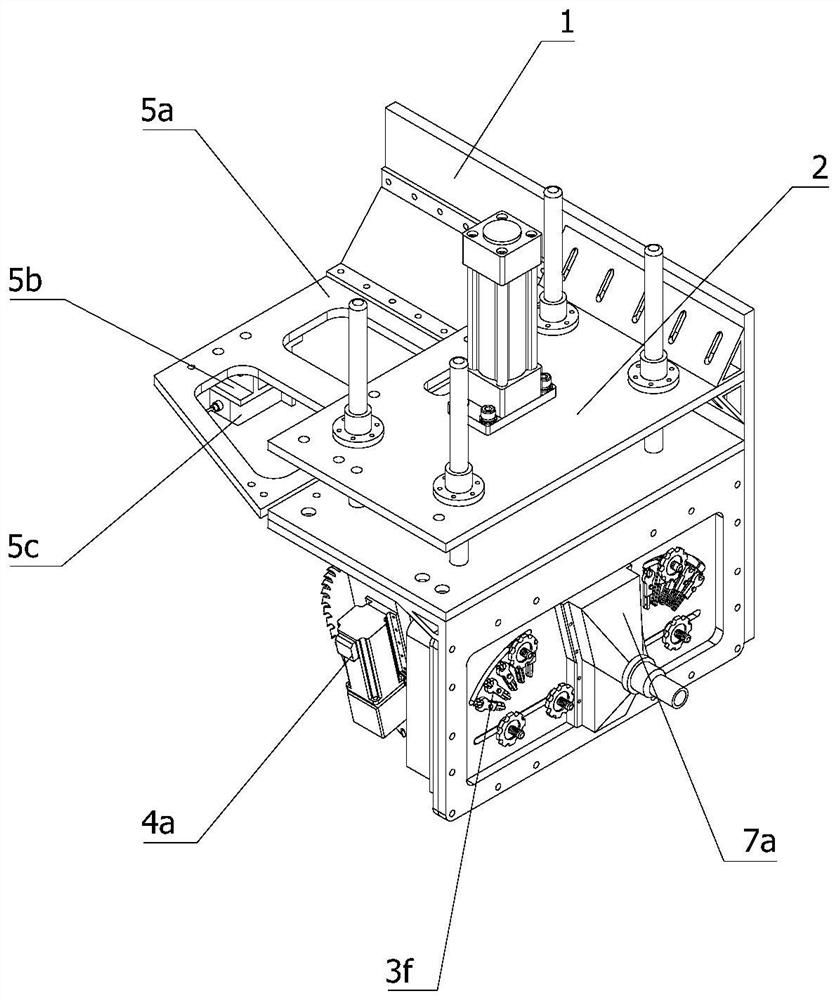

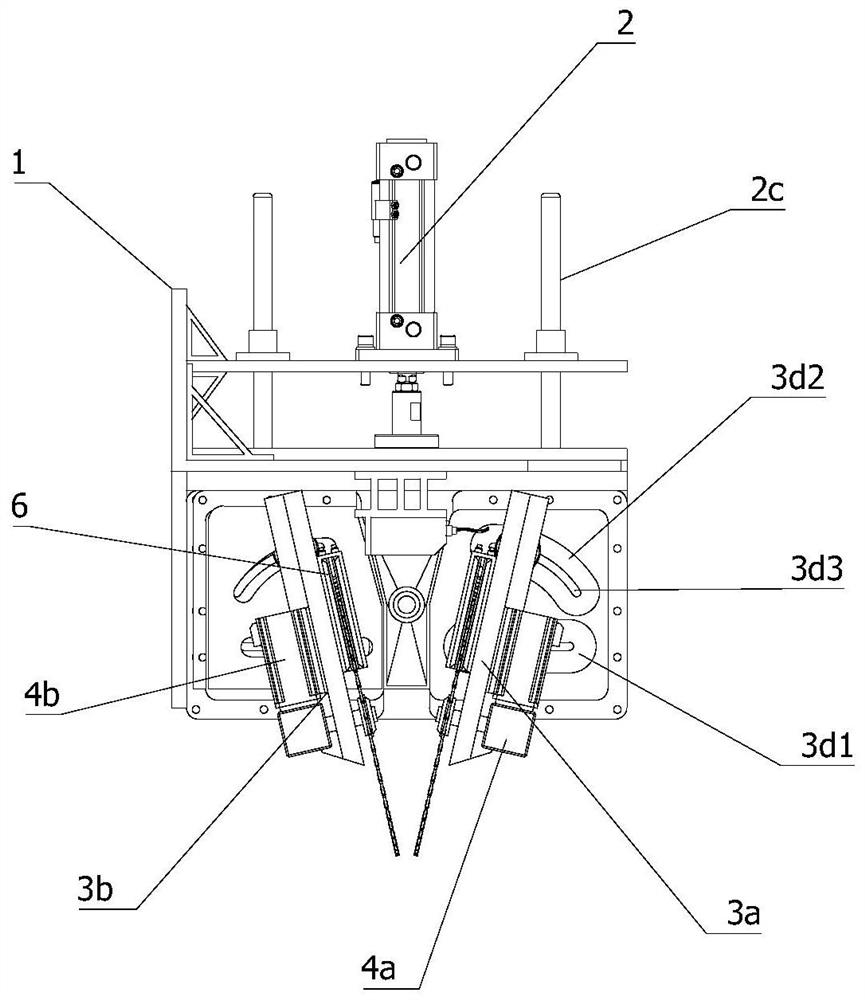

[0038] like Figure 1 to Figure 9 As shown, this application provides:

[0039]A road surface slitting device with automatic adjustment function monitoring line installation, comprising a frame 1, a longitudinal attitude adjustment device 2, an angle adjustment device 3, a first angle adjustment mechanism 3a, a second angle adjustment mechanism 3b, and a slitting device 4. The distance detection unit 5, the cooling unit 6 and the cleaning unit 7; the longitudinal attitude adjustment device 2 is fixedly installed on the frame 1 in a vertical state, and the angle adjustment device 3 is vertically fixed and installed on the output end of the longitudinal attitude adjustment device 2, so The angle adjustment device 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com