Environment-friendly high-pressure water cutting machine for automobile parts

A technology of auto parts and water cutting machine, which is applied in the direction of metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve the problems that cannot meet the cutting requirements of special-shaped auto parts, so as to prolong the service life and improve the adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment is a high-pressure water cutting machine for environmentally friendly automobile parts.

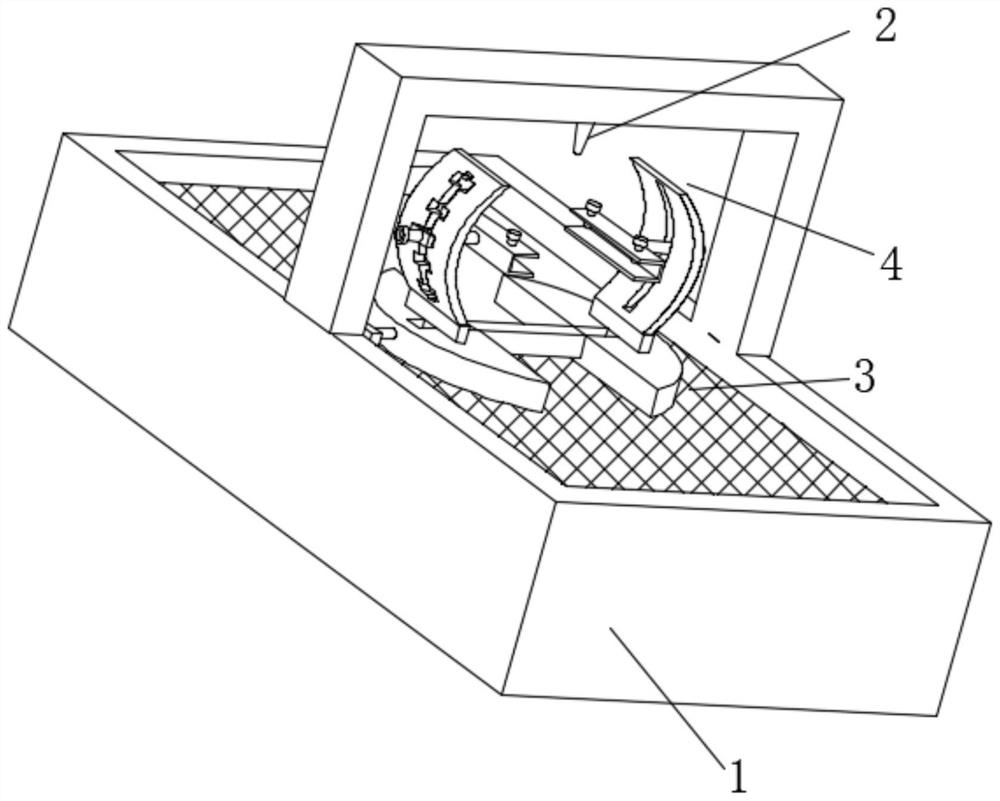

[0038] see Figure 1-7 , an environmentally friendly high-pressure water cutting machine for automobile parts, including a cutting table 1 and a water jet body 2, the water jet body 2 is arranged on the top of the cutting table 1, the top of the cutting table 1 is provided with an adjustment mechanism 3, and the internal installation of the adjustment mechanism 3 There is a fixed mechanism 4;

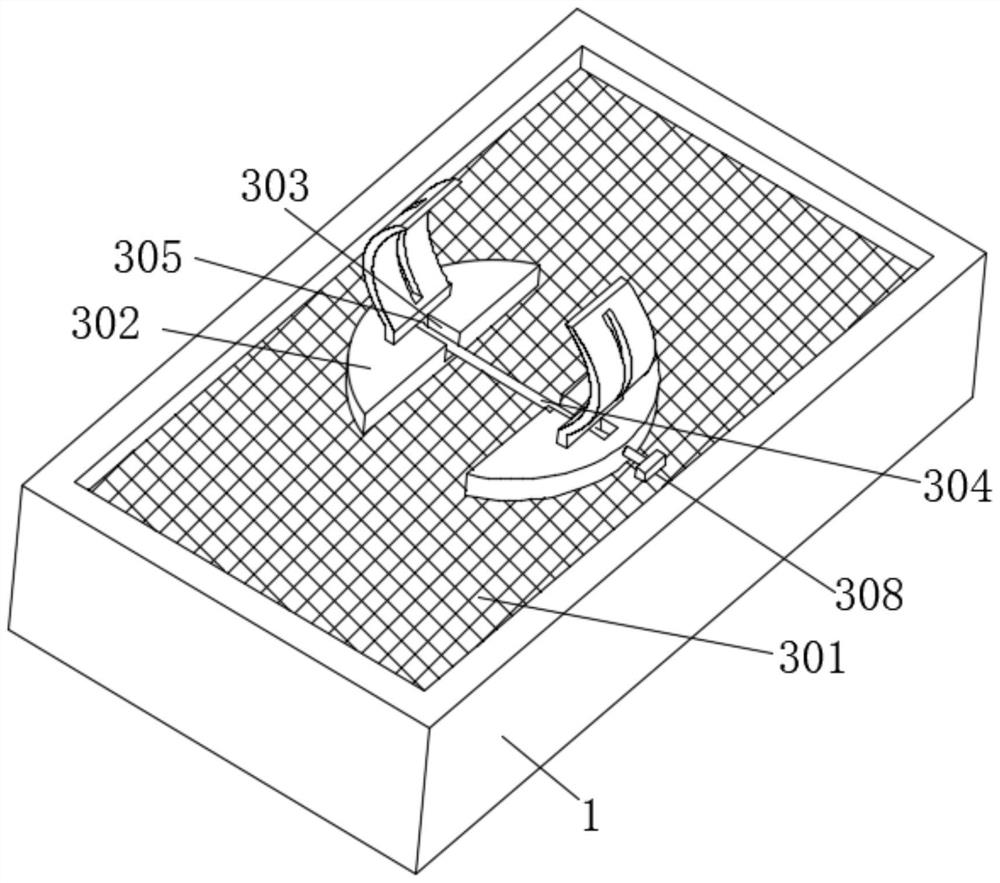

[0039] The adjustment mechanism 3 includes a grid table 301, two meniscus 302 are installed on the top of the grid table 301, a chute 303 is opened on the top of the two meniscus 302, and a bidirectional screw rod is movably connected between the two chute 303 304, a slider 305 is installed on the outer side wall of the two-way screw 304 near the two sliding grooves 303, and the top of the two sliders 305 is fixedly connected with an arc-shaped enclosure plate 306;

[0040]...

Embodiment 2

[0058] This embodiment is a specific implementation of the adjustment mechanism 3 of the high-pressure water jet cutting machine for environmentally friendly automobile parts.

[0059] An adjustment mechanism 3 of a high-pressure water cutting machine for environmentally friendly automobile parts, including a grid table 301, two meniscus 302 are installed on the top of the grid table 301, and the top of the two meniscus 302 are provided with chute 303, A two-way screw 304 is movably connected between the chute 303, and a slider 305 is installed on the outer side wall of the two-way screw 304 near the two chute 303, and the tops of the two sliders 305 are fixedly connected with an arc. Hoarding 306 .

[0060] Through the above technical solution, the two-way screw 304 is rotated, and the two-way screw 304 drives the two sliders 305 to rotate. The two sliding blocks 305 can drive the two arc-shaped enclosure plates 306 to adjust the distance of each other, so as to adapt to the...

Embodiment 3

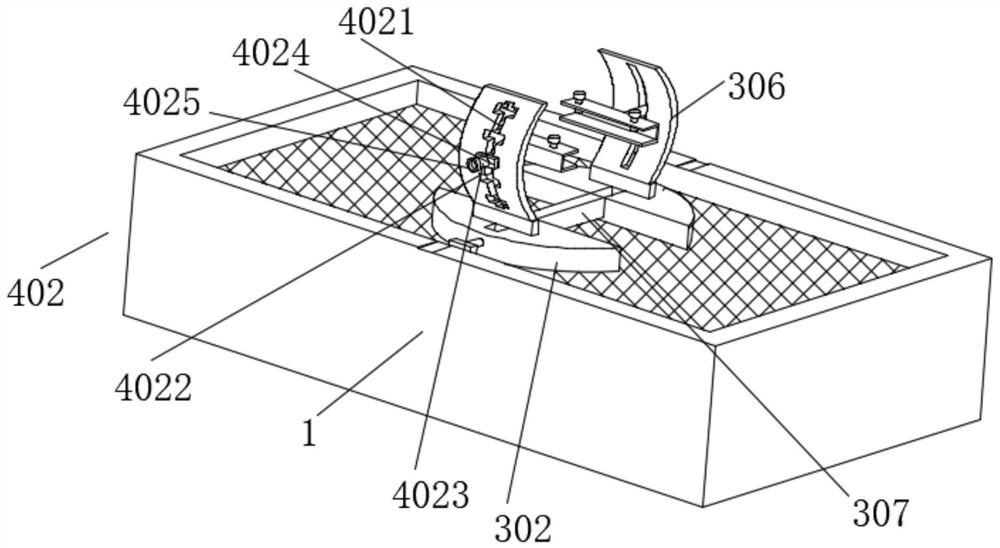

[0062] This embodiment is a specific implementation of the fixing mechanism 4 of a high-pressure water jet cutting machine for environmentally friendly automobile parts.

[0063] A fixing mechanism 4 of a high-pressure water cutting machine for environmental protection automobile parts includes two struts 401, one end of the two struts 401 is provided with a sliding member 402, the other ends of the two struts 401 are oppositely arranged, and the two sliding members 402 A clamp 403 is provided on the opposite end.

[0064] Through the above technical solution, by turning the adjusting rod 4023, the strut 401 is driven to adjust along the outer arc of the arc-shaped enclosure plate 306, so as to complete the adjustment of the inclination angle, so as to change the cutting angle of the auto parts and improve the adaptability of the device It can meet the different cutting needs of special-shaped parts such as auto parts.

[0065] When in use, the two-way screw 304 is rotated, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com