Granulator

A granulator, squeeze casting technology, applied in solid separation, sieve, grid, etc., can solve problems such as uneven rubber particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

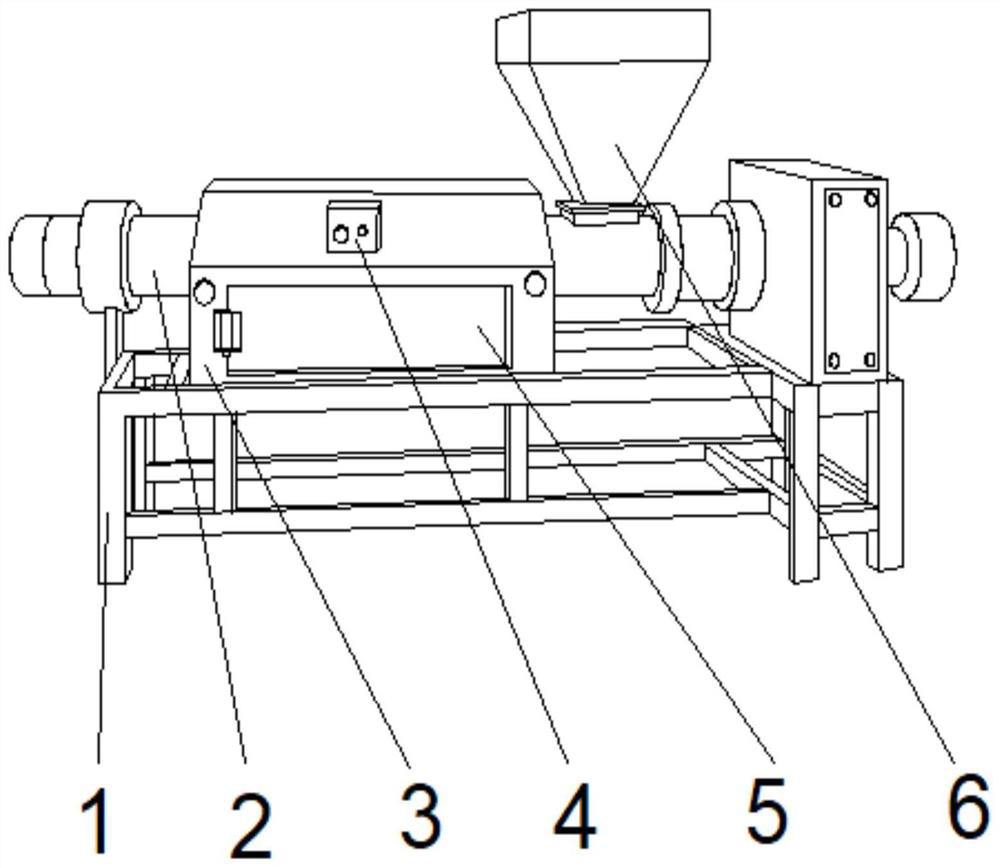

[0034] Such as Figure 1-3 , a technical solution proposed by the present invention: a granulator, including a base 1, a cooling box 3 is fixedly connected to the middle position of the top of the base 1, and a box door 5 is provided at the middle position of the front bottom of the cooling box 3, and the cooling box 3 A controller 4 is fixedly connected to the middle position of the top of the front, and the outer walls of both sides of the cooling box 3 are provided with extruding devices 2. A heating bucket 6 is provided.

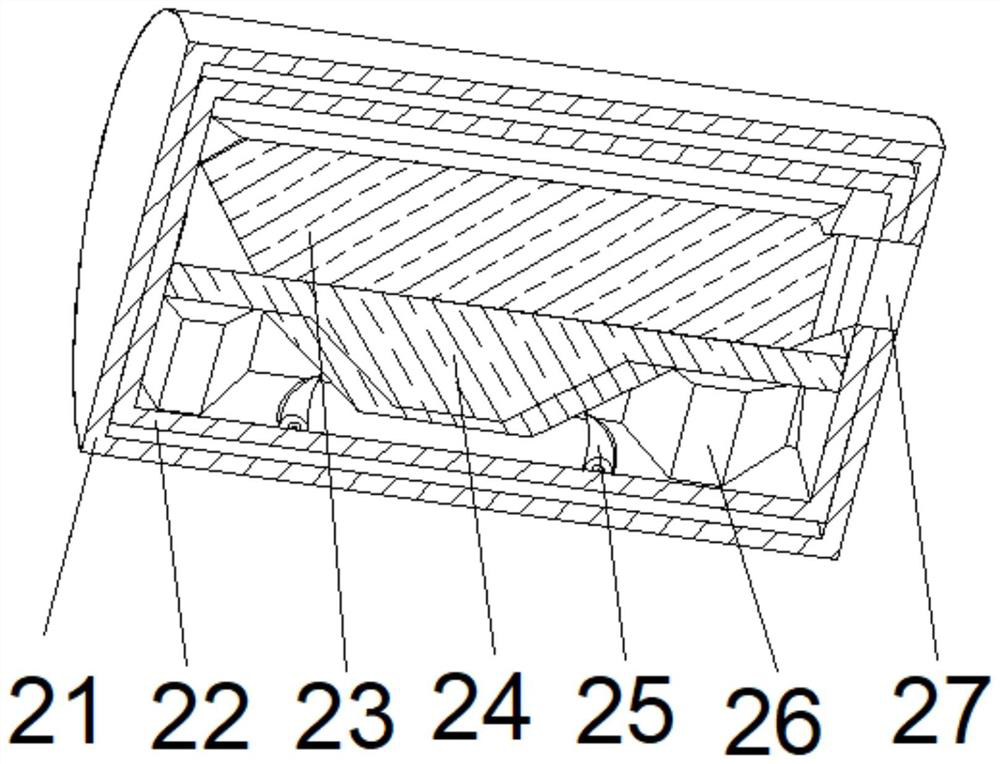

[0035] Wherein, the extruding device 2 comprises a casing 21, and the top right side of the casing 21 is provided with a feeding port 27, and the middle position of the inner cavity bottom of the outer casing 21 is fixedly connected with an extrusion chamber 22, and the middle position of the inner cavity bottom of the extrusion cavity 22 is fixed. Connected with blocking teeth 25, both sides of the inner cavity bottom of the extrusion chamber 22 are fixe...

Embodiment 2

[0039] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the collection mechanism 24 includes a collection cavity 241, a collection mechanism 243 is provided at the middle of the bottom of the cavity of the collection cavity 241, and the bottom of the cavity of the collection cavity 241 is located at Both sides of the screening mechanism 243 are fixedly connected with material guide plates 242, the top of the collection chamber 241 is fixedly connected with a combination frame 244, and the bottom of the combination frame 244 is provided with an outrigger plate 245, and the outrigger plate 245 is fixed on one side away from the combination frame 244. A force-receiving surface 248 is connected, a linkage frame 246 is fixedly connected to the middle of the force-receiving surface 248 , and a scraper 247 is fixedly connected to the middle position of the bottom of the linkage frame 246 .

[0040] When in use, the filte...

Embodiment 3

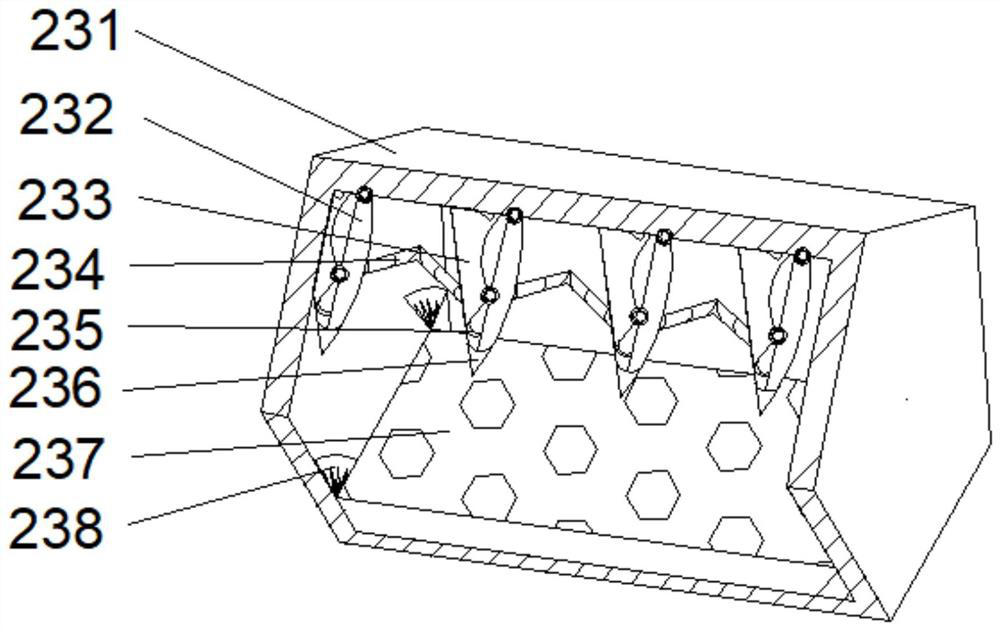

[0042] Such as Figure 1-5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the cutting mechanism 236 includes a fixed seat 2361, and the middle part of the fixed seat 2361 is fixedly connected with a friction surface 2365, and the two sides of the fixed seat 2361 are provided with There is a top block 2363, and the position of the top block 2363 away from the fixed seat 2361 is fixedly connected with a blade 2364, and the middle part of one side of the top block 2363 near the fixed seat 2361 is provided with a front swing plate 2362.

[0043] Wherein, the screening mechanism 243 includes a receiving block 2431, a brush block 2433 is arranged on the top of the receiving block 2431, a collection bin 2434 is arranged at the middle of the bottom of the receiving block 2431, and a tapered hole 2432 is opened on the top of the inner cavity of the receiving block 2431.

[0044] When in use, the rubber is heated in the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com