High-strength reinforcing steel bar with spiral fins and processing method of high-strength reinforcing steel bar

A processing method and technology of ribbed steel bar, applied in the field of high-strength spiral ribbed steel bar and its processing, can solve the problems of poor ductility of spiral rib steel wire, inability to connect spiral rib steel wire with threads, narrow use range, etc., and achieve high anchorage strength and rigidity, good Anchoring performance, beneficial to the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

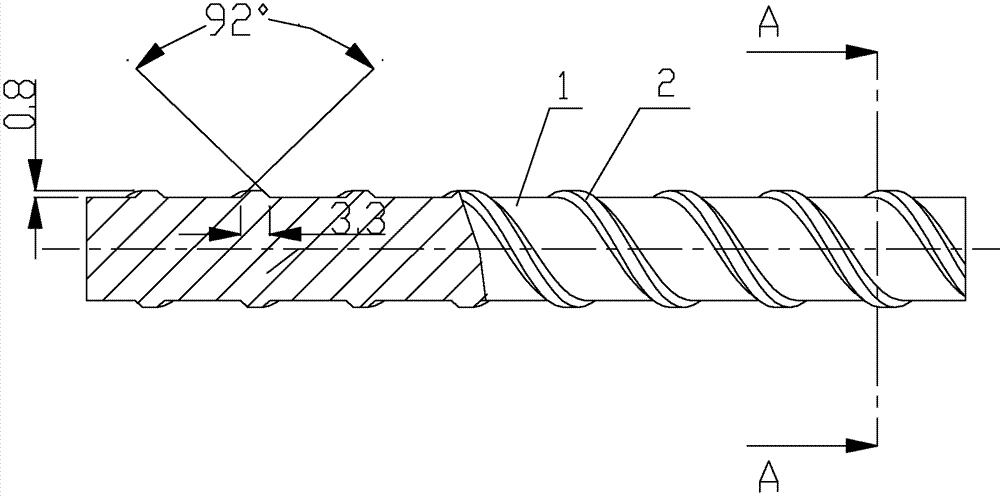

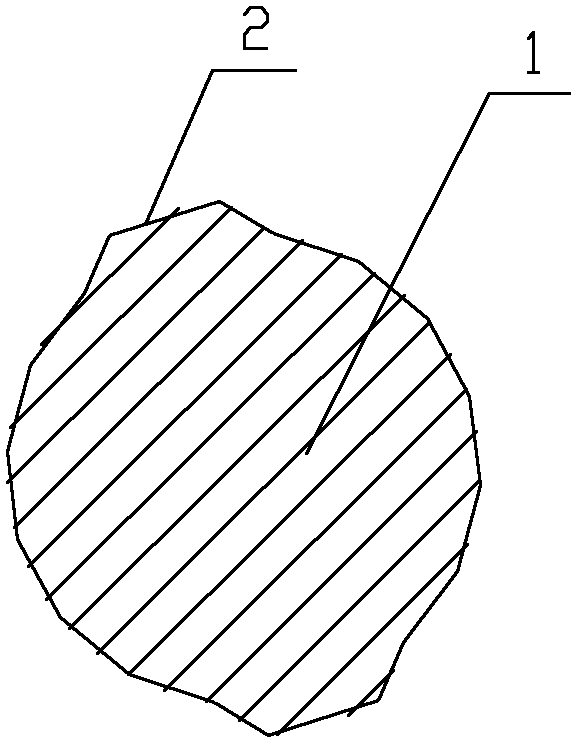

[0030] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle between the two tangent lines between the two sides and the surface of the steel bar is 90°, and the width of each continuous spiral rib is 3mm and the height is 0.5mm.

[0031] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.25%, Si: 0.1%, Mn: 0.3%, Nb: 0.04%, Cr: 0.08%, V: 0.01%, B: 0.002 %, Mo: 0.001%, Al: 0.015%, S: 0.002%, Ti: 0.008%, Ni: 0.004%, compound rare earth: 3%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 25%, Ce: 20%, Y: 8%, Sc: 12%, Gd: 5%, Sm: 5%, Dy: 5%, Pr: 20 %.

[0032] The processing method of high-streng...

Embodiment 2

[0037] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle formed by the two tangent lines between the two sides and the reinforcement surface is 92°, and the width of each continuous spiral rib is 3.3mm and the height is 0.7mm.

[0038] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.3%, Si: 0.15%, Mn: 0.4%, Nb: 0.045%, Cr: 0.085%, V: 0.03%, B: 0.0025 %, Mo: 0.002%, Al: 0.025%, S: 0.0025%, Ti: 0.0085%, Ni: 0.0045%, compound rare earth: 4%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 33%, Ce: 17%, Y: 5%, Sc: 10%, Gd: 5%, Sm: 7%, Dy: 3%, Pr: 20 %.

[0039] The processing method of high...

Embodiment 3

[0044] This embodiment proposes a high-strength spiral rib steel bar, the structure shown in 1, including a steel bar body 1 and two spiral ribs 2 on the surface of the steel bar body, the spiral ribs 2 are continuously distributed on the surface of the steel bar body, and each continuous spiral rib 2 The angle between the two tangent lines between the two sides and the steel bar surface is 95°, and the width of each continuous spiral rib is 3.5mm and the height is 0.9mm.

[0045] The high-strength spiral rib steel bar of this embodiment contains the following components by weight percentage: C: 0.4%, Si: 0.2%, Mn: 0.45%, Nb: 0.05%, Cr: 0.09%, V: 0.04%, B: 0.003 %, Mo: 0.003%, Al: 0.03%, S: 0.003%, Ti: 0.009%, Ni: 0.005%, compound rare earth: 5%, and the balance is Fe. In the composite rare earth, the following components are contained by weight percentage: La: 35%, Ce: 15%, Y: 7%, Sc: 11%, Gd: 4%, Sm: 6%, Dy: 4%, Pr: 18 %.

[0046] The processing method of high-strength spi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com