Method for producing thin wall plastering mortar for buildings by using artificial stone, marble and granite sawdust solid waste

A technology for artificial granite and marble, applied in the field of comprehensive utilization of solid waste, can solve problems such as excessive dust, and achieve the effects of increasing the rubbing contact surface, preventing easy precipitation, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

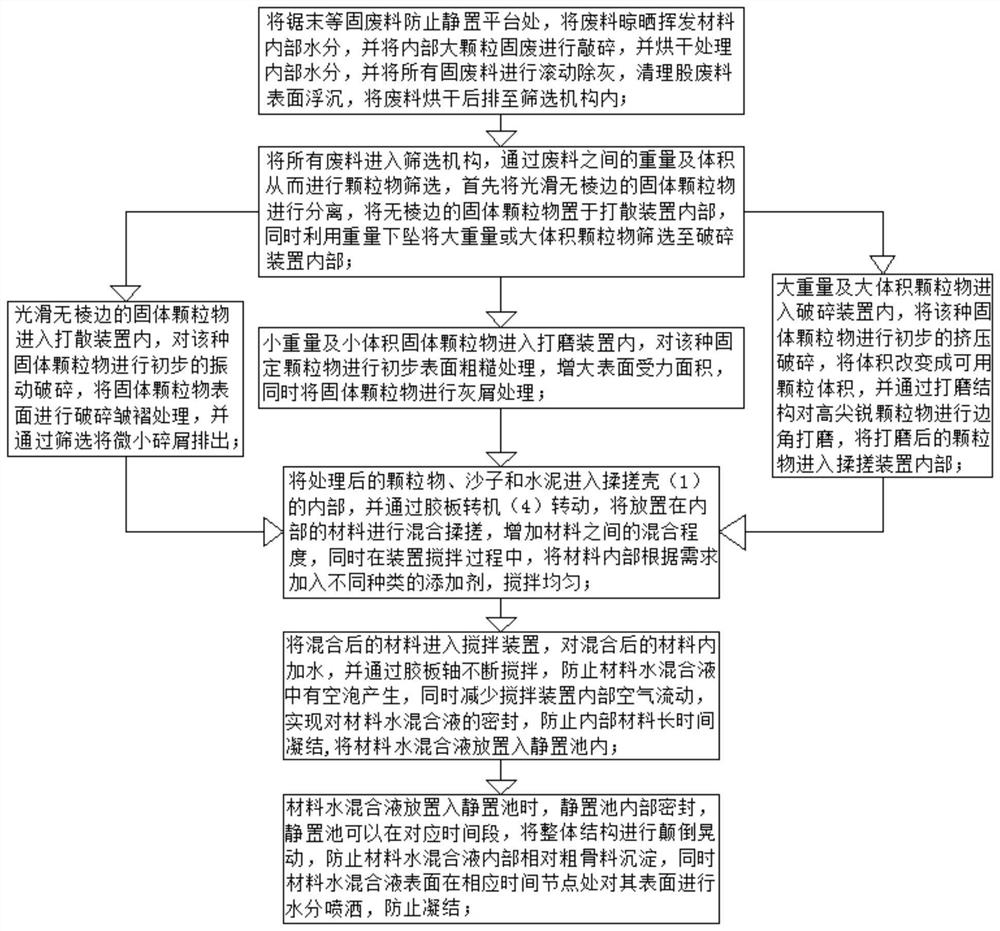

[0045] Such as figure 1 As shown, the present invention provides a kind of technical scheme: a kind of method with artificial granite, marble, granite sawdust solid waste production thin plaster for construction, comprises the following steps:

[0046] Step 1. Prevent solid waste such as sawdust from standing on the platform, dry the waste to volatilize the internal moisture of the material, crush the internal large-particle solid waste, and dry the internal moisture, and roll all the solid waste to remove Ash, clean up the floating and sinking of the waste material surface, dry the waste material and discharge it into the screening mechanism;

[0047] Step 2. Put all the waste into the screening mechanism, and screen the particles through the weight and volume of the waste. First, separate the smooth and edgeless solid particles, and place the edgeless solid particles inside the dispersing device. At the same time Use weight drop to screen large weight or large volume partic...

Embodiment 2

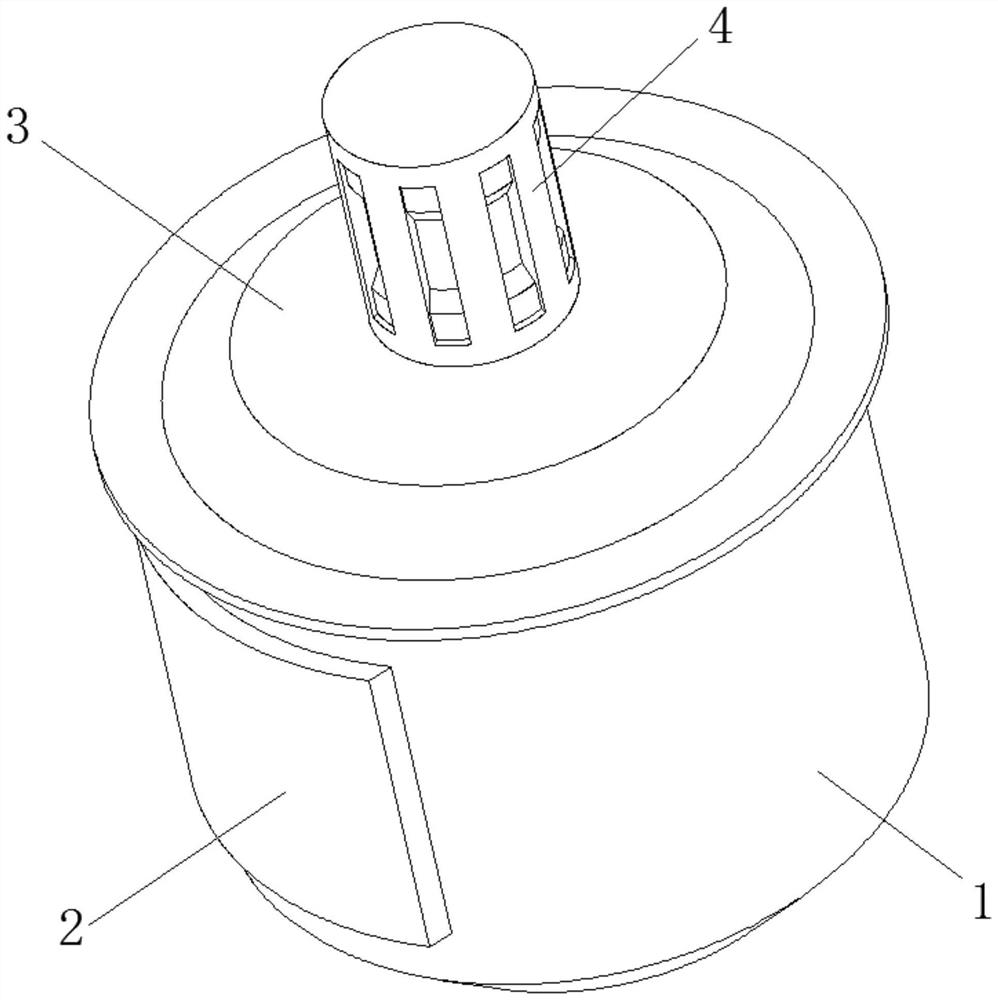

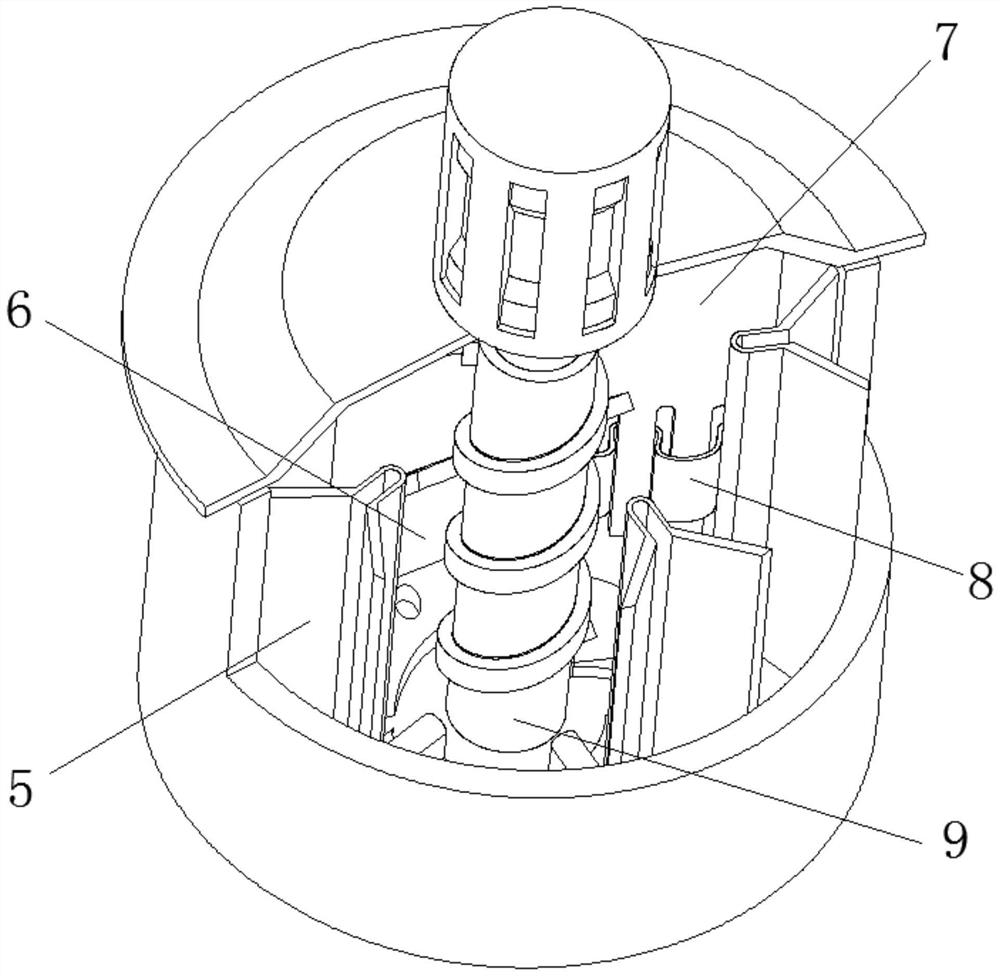

[0064] Such as Figure 2-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the kneading device in the step 4 includes a kneading shell 1, the outer surface of the kneading shell 1 is fixedly connected with an operation panel 2, the The top of the kneading shell 1 is provided with a splash-proof top plate 3, and the middle of the splash-proof top plate 3 is rotatably connected with a stirring turntable 4, and the output end of the bottom of the stirring turntable 4 is fixedly connected with a stirring shaft device 9, and the kneading shell The inner wall of 1 is respectively fixedly connected with a friction device 5 and an extrusion chamber 7, the opposite side of the friction device 5 is provided with an extrusion chamber 7, and the bottom of the extrusion chamber 7 is fixedly connected with a spring plate 8, the extrusion A sub-sieve plate 6 is fixedly connected between the opposite surfaces of the cavity 7 .

[0065] By arrangin...

Embodiment 3

[0074] Such as Image 6 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the stirring shaft device 9 includes an inner rotating shaft 93, and the top of the inner rotating shaft 93 is fixedly connected to the bottom of the stirring rotor 4 At the output end of the inner rotating shaft 93, the surfaces of the upper and lower ends of the inner rotating shaft 93 are fixedly connected with limiting blocks 91 .

[0075] A stirrer 92 is fixedly connected between the opposite surfaces of the limiting block 91 , and the outer surface of the inner rotating shaft 93 is covered with a spiral rubber plate 94 , and the two ends of the spiral rubber plate 94 are fixedly connected to the limiting block 91 The surface of the spiral rubber plate 94 is provided with an inner groove 95 . When the rotation speed of the mixing machine 4 increases, the spiral rubber plate 94 can increase the extrusion area, provide high-speed pressurizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com