Cutting machine

A kind of cutting machine, organic technology, applied in the direction of metal processing machinery parts, large fixed members, electric processing equipment, etc., can solve the problems of complex structure and high price of wire cutting machine, and achieve simple structure, low cost, and adjustable cutting angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

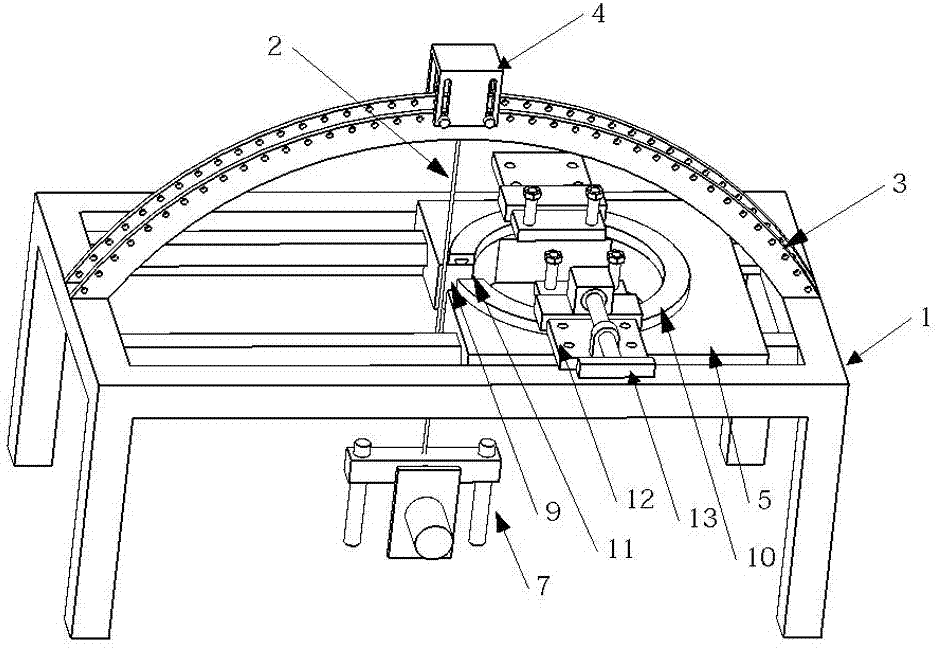

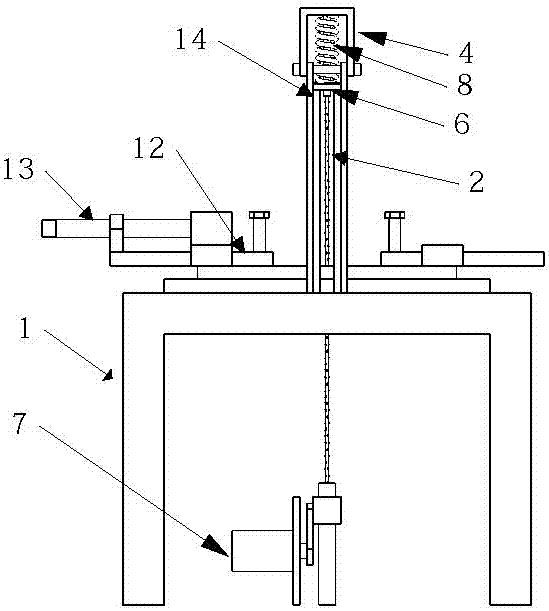

[0012] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The cutting machine includes a frame 1 and a cutting rope 2. Two arc-shaped beam frames 3 are arranged side by side on the frame 1. A slide frame 4 is arranged on the two arc-shaped beam frames 3. The slide frame The position of 4 on the beam frame 3 can be adjusted, and the sliding frame 4 can also move radially on the beam frame 3. The inner side of the beam frame 3 is provided with a boss 14, and the boss 14 is provided with a slider 6, so that The upper end of the sliding frame 4 is connected to one end of the cutting rope 2, and the other end of the cutting rope 2 passes through the slider 6 to connect to the lifting drive device 7, and the cutting rope 2 between the sliding frame and the slider 6 is provided with an elastic reset member 8, which is elastically The reset member 8 is a spring; the frame 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com