Automatic pruning device for poplars

A pruning and automatic technology, applied in cutting tools, cutting equipment, gardening, etc., can solve the problems of large pruning machinery not suitable for small operating space, insufficient pruning height, and high labor intensity, and achieve the degree of pruning automation. Height, reduce the length of branches and piles, and improve the effect of wood quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

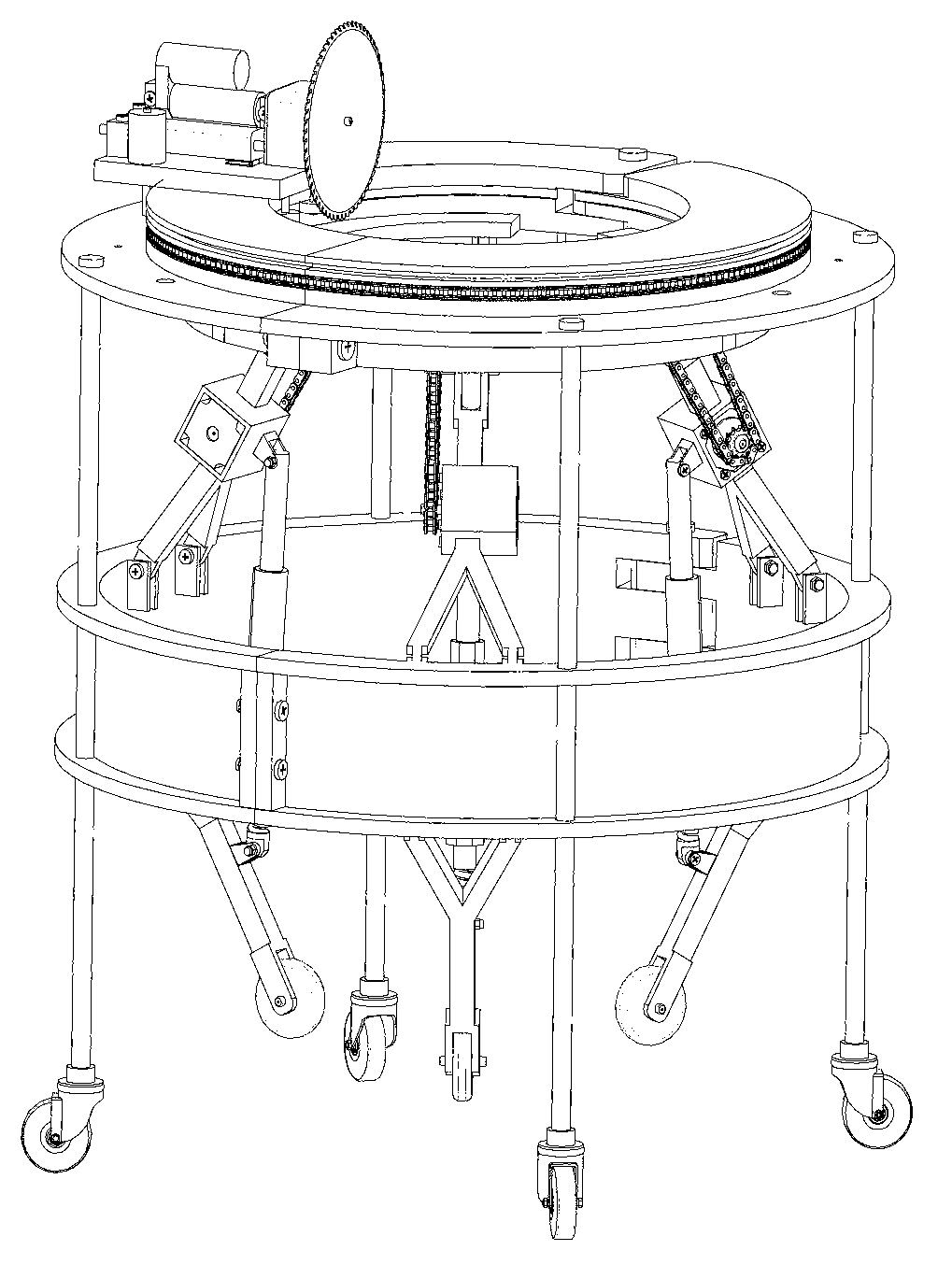

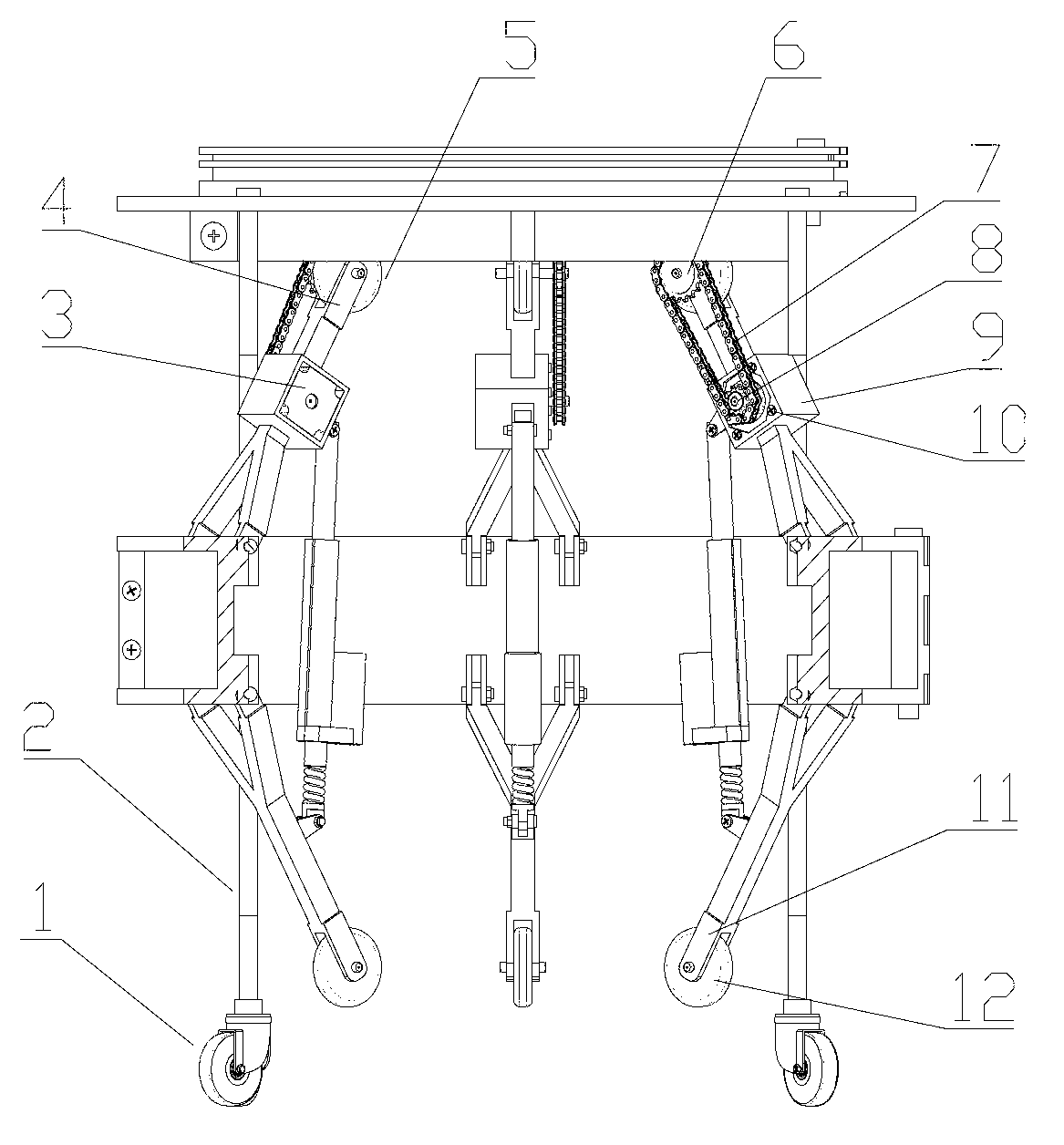

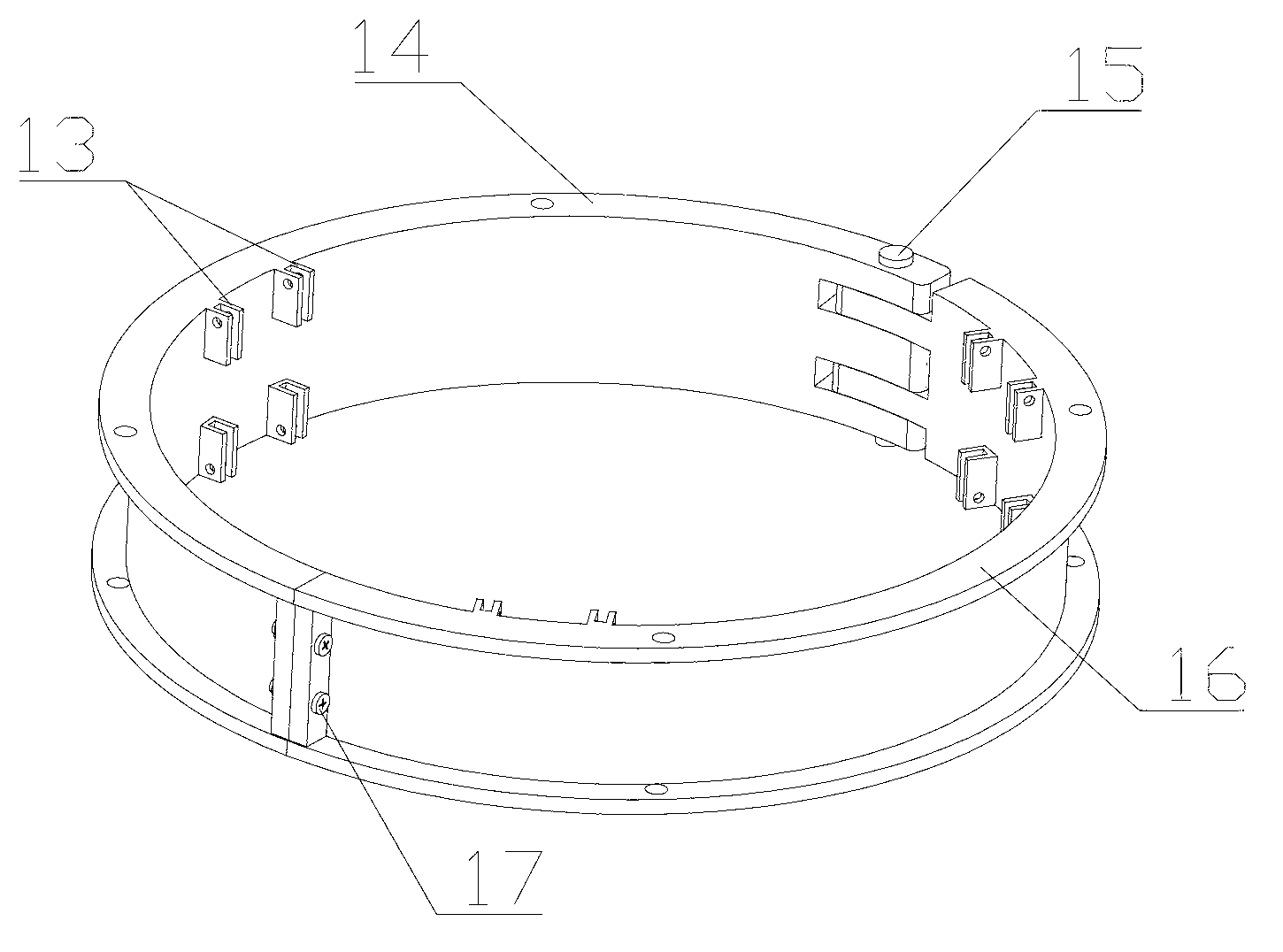

[0022] A poplar automatic pruning device such as figure 1 As shown, including: climbing mechanism, rotating mechanism and pruning saw actuator. The climbing mechanism integrates the driving and pressing functions, and provides the required power for the machine to climb while ensuring that the wheels are pressed against the tree trunk; the rotating mechanism includes a turntable structure and a slewing platform sub-mechanism. The turntable structure is fixed on the upper part of the climbing mechanism by connecting the support rods, and the application of the circular track provides a 360° rotation requirement for the slewing platform. The rotary platform sub-mechanism is placed on the turntable structure, and the two are connected together through relevant cooperation. The rotary motor provides power for the rotary platform so that it can rotate freely around the turntable structure; the pruning saw actuator is connected to the rotary platform sub-mechanism, The pruning saw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com