Material breaking cutting device

A cutting device and material cutting technology, which is applied to large fixed members, metal processing machinery parts, metal processing equipment, etc. Simple, improved machining accuracy, and improved application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

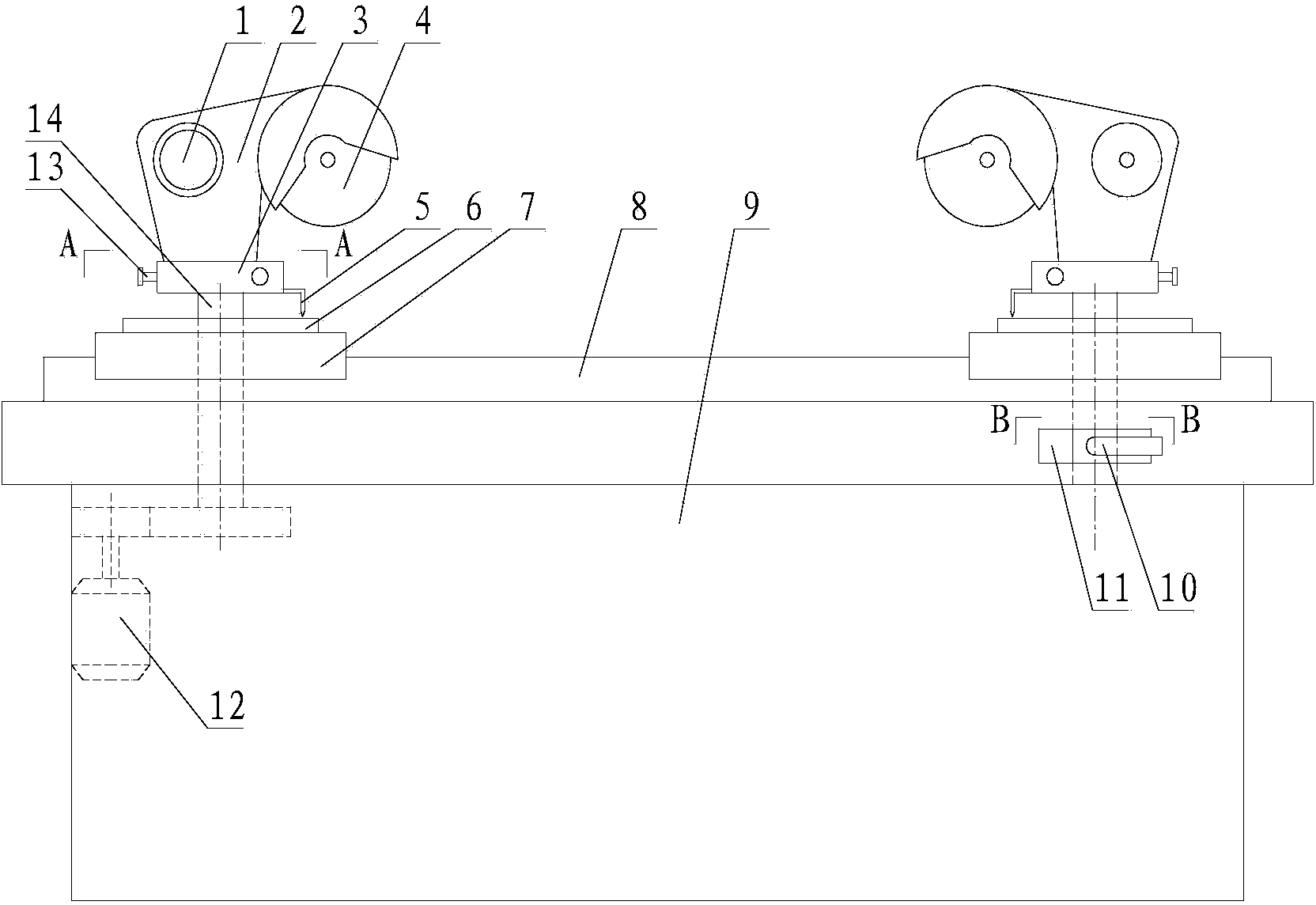

[0018] A material cutting device, comprising a work platform 9, a base 3, a blade 4, a blade motor 1 and a blade displacement drive device 2, a guide rail 8 is installed on the work platform, and a blade is connected to the base through a blade displacement drive device, the blade The central shaft of the blade motor is connected. Since the above is a known technology, its structure will not be repeated here.

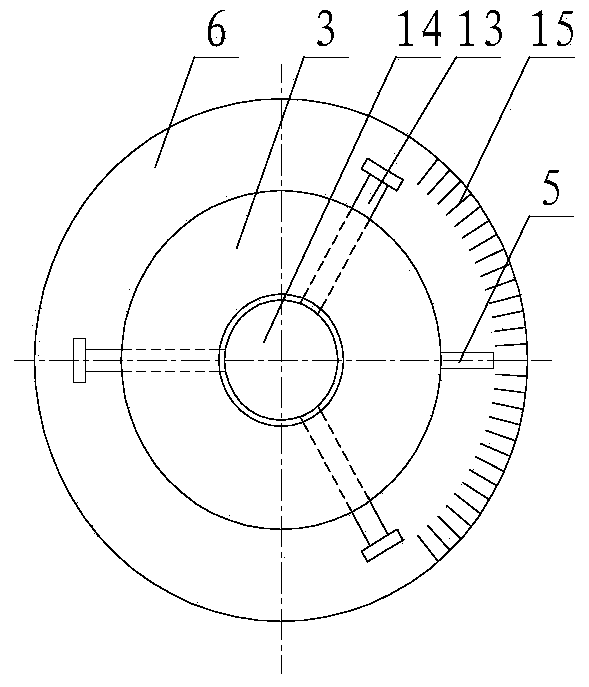

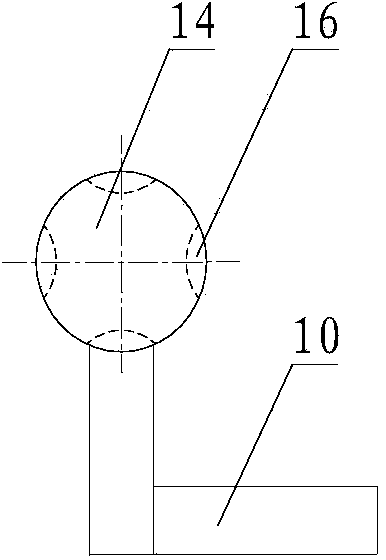

[0019] The innovation of the present invention is: a sliding sleeve 7 is installed on the guide rail of the working platform, an angle display board 6 is installed on the sliding sleeve, and an angle scale 15 is made on the angle display board. A through hole is made at the axis of the sliding sleeve and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com