Internal cutting type pipeline cutting machine

A pipe cutting machine, inward cutting technology, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of manual adjustment of the cutting torch and base metal, inability to cut bevels, complicated installation process, etc. Easy to move, easy to install, compact line structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

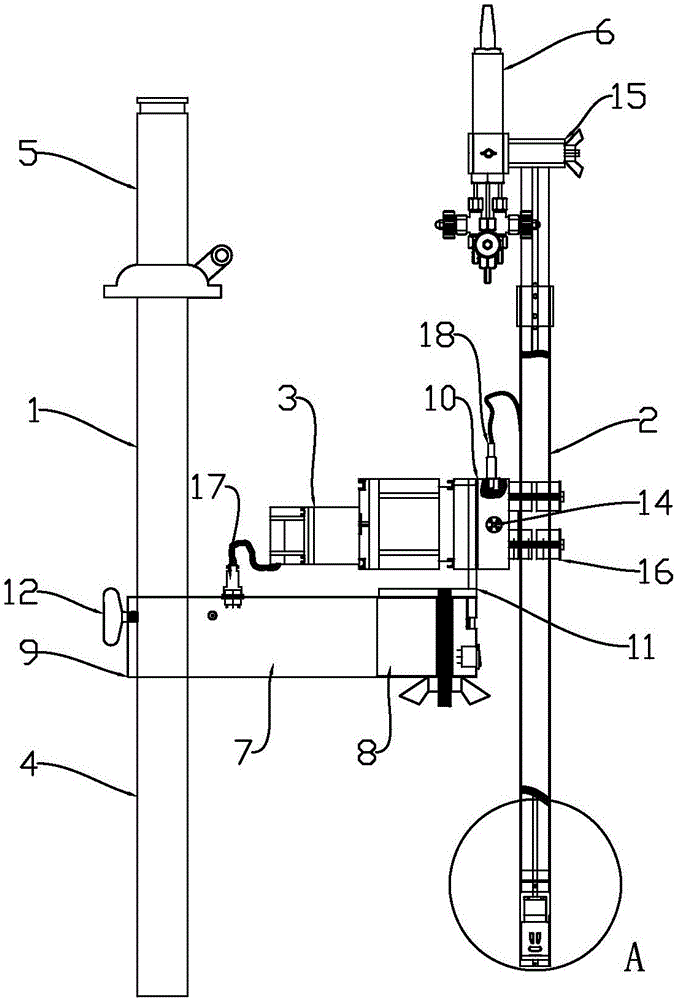

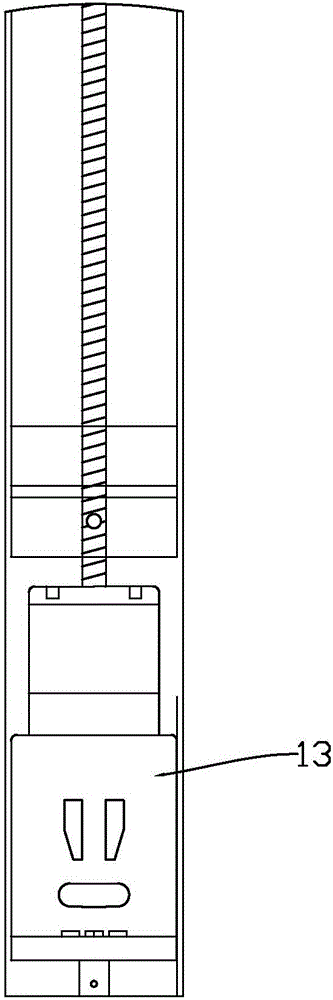

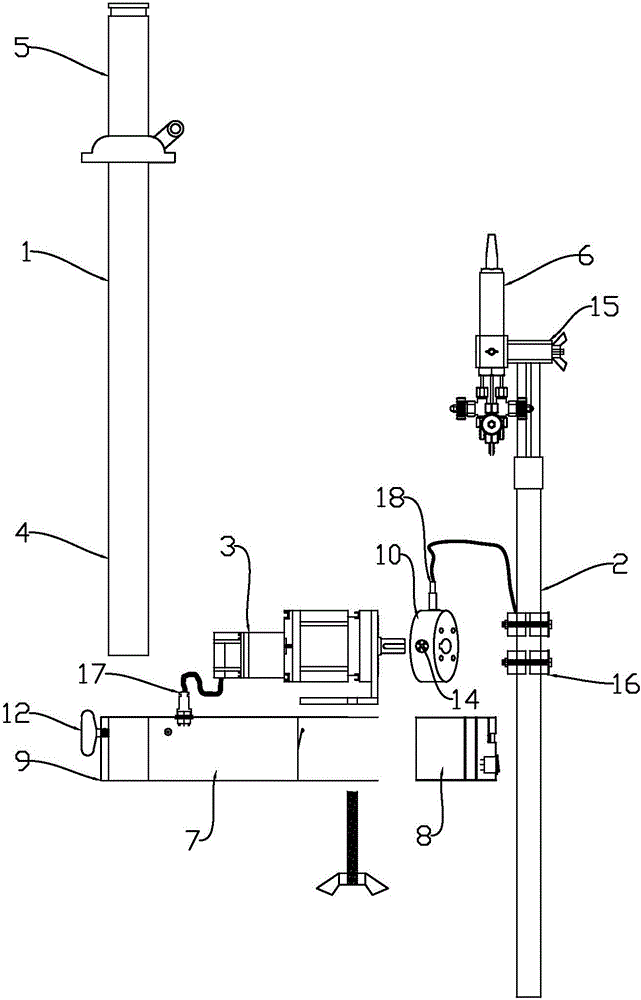

[0018] Such as Figure 1 to Figure 5 As shown, an in-cut type pipe cutting machine includes a static support 1, a moving support 2 and a stepping motor 3, and the static support 1 includes a support main body 4 and a telescopic fastening device 5 arranged at the end of the support main body 4, The end of described movable support 2 is provided with cutting torch 6, and cutting torch 6 can be semi-automatic flame cutting torch, for example the cutting torch of CG1-30 type cutting torch, and this kind cutting torch needs manual ignition, also can be straight plasma cutting torch , such as the P80 type cutting torch, this kind of cutting torch can be automatically ignited by a switch, in order to make the cutting nozzle of the cutting torch 6 face the inner wall of the pipeline during the rotation process, it is best to use a straight cutting torch, and the stepping motor 3 is fixed On the static support 1 and can drive the movable support 2 to rotate, the stepper motor 3 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com