A steel bar cutting device

A technology for cutting equipment and steel bars, which is applied in the field of steel bar cutting equipment, and can solve the problems of human operator's physical danger and low degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

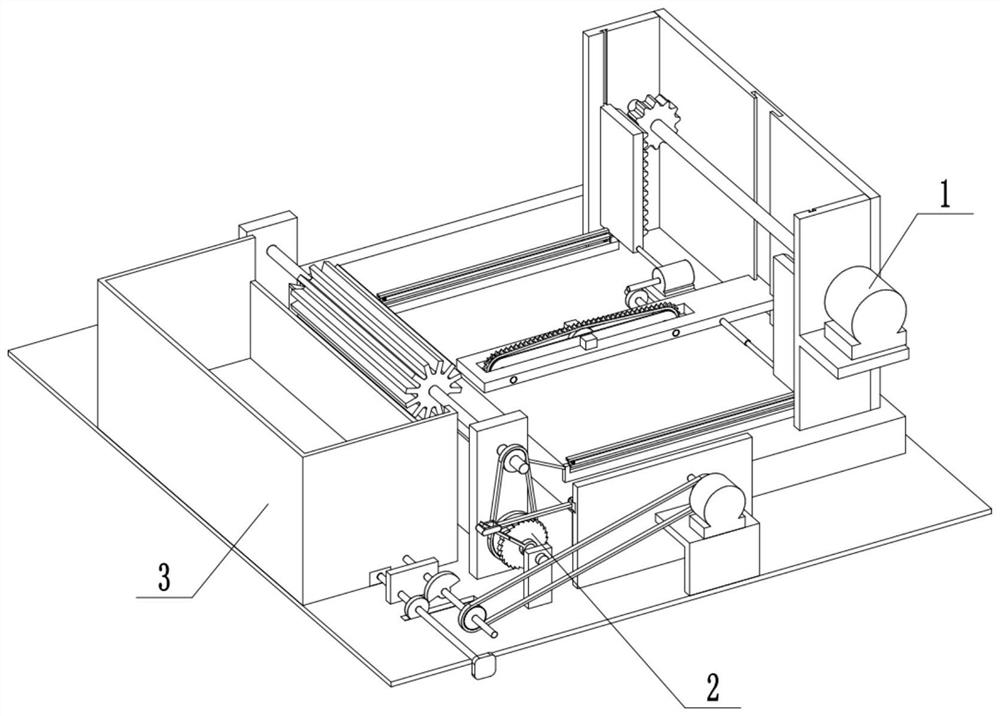

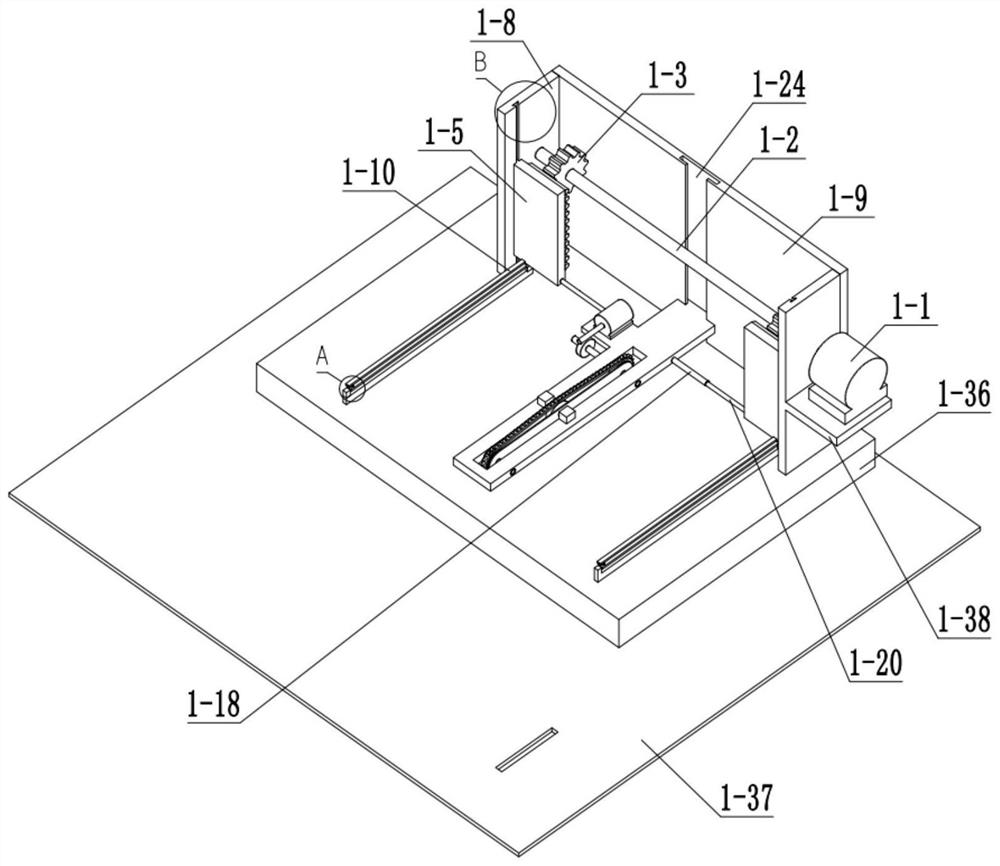

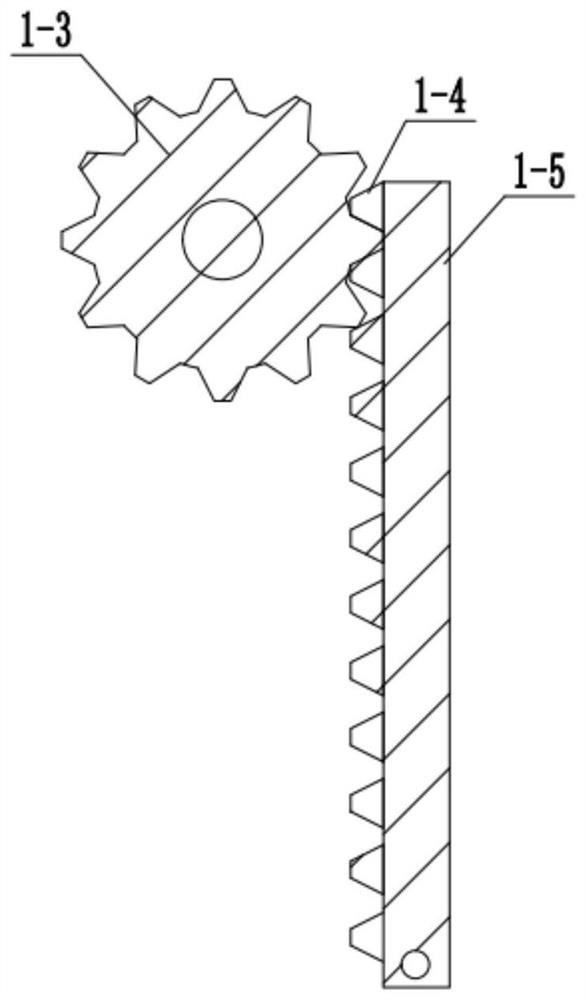

[0033] Combine below Figure 1-19 Describe this embodiment, a steel bar cutting equipment, including a cutting assembly 1, a feeding assembly 2 and a material box assembly 3, characterized in that: the cutting assembly 1 includes a servo motor 1-1, a lifting shaft 1 -2, lifting gear 1-3, lifting rack 1-4, lifting plate 1-5, lifting plate slide rail 1-6, lifting plate chute 1-7, side plate I1-8, side plate II1-9, Lifting rod 1-10, spherical chute 1-11, ball head 1-12, ball head column 1-13, ball head column lug 1-14, turret 1-15, fixed block 1-16, fixed frame 1 -17, threaded sliding cylinder 1-18, T-shaped hole 1-19, support shaft 1-20, cutting frame chute Ⅰ1-21, cutting frame slide rail 1-22, cutting frame 1-23, cutting Frame chute Ⅱ1-24, motor Ⅰ1-25, worm 1-26, worm gear 1-27, worm shaft 1-28, sprocket Ⅰ1-29, chain Ⅰ1-30, tensioning sprocket 1-31, tensioning chain Wheel shaft 1-32, sprocket II 1-33, sprocket II shaft 1-34, cutting knife 1-35, cutting bottom plate 1-36, bott...

specific Embodiment approach 2

[0037] Combine below Figure 1-19 This embodiment will be described. This embodiment will further explain Embodiment 1. The material box assembly 3 includes a sprocket V3-1, a chain III3-2, a sprocket VI3-3, a sprocket VI shaft 3-4, a half Gear 3-5, gear 3-6, material box lifting shaft 3-7, lifting shaft bracket 3-8, handle 3-9, lifting slider Ⅰ 3-10, lifting slider Ⅱ 3-11, carriage 3-12 , Lug Ⅰ3-13, lifting rod Ⅰ3-14, supporting lug Ⅱ3-15, lifting rod Ⅱ3-16, supporting lug Ⅲ3-17, material box lifting plate 3-18 and material box 3-19, sprocket Ⅴ3-1 It is connected with motor Ⅱ shaft 2-2, sprocket Ⅴ3-1, chain Ⅲ3-2, sprocket Ⅵ3-3 sprocket chain, sprocket Ⅴ3-1 and sprocket Ⅵ3-3 transmission ratio is 1:1, chain The wheel Ⅵ 3-3 is connected with the sprocket Ⅵ shaft 3-4, the sprocket Ⅵ shaft 3-4 is connected with the half gear 3-5, the toothed part of the half gear 3-5 is meshed with the gear 3-6, and the gear 3- 6 is connected with the lifting shaft 3-7 of the material box, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com