Adjustable single-drive tapered tooth cutting device

A cutting equipment, single-drive technology, applied in mechanical equipment, metal processing equipment, gear teeth, etc., can solve the problems of vulnerability, heavy cutting equipment load, affecting the quality of workpieces, etc., to reduce the cost of use, ensure processing quality, improve The effect of generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

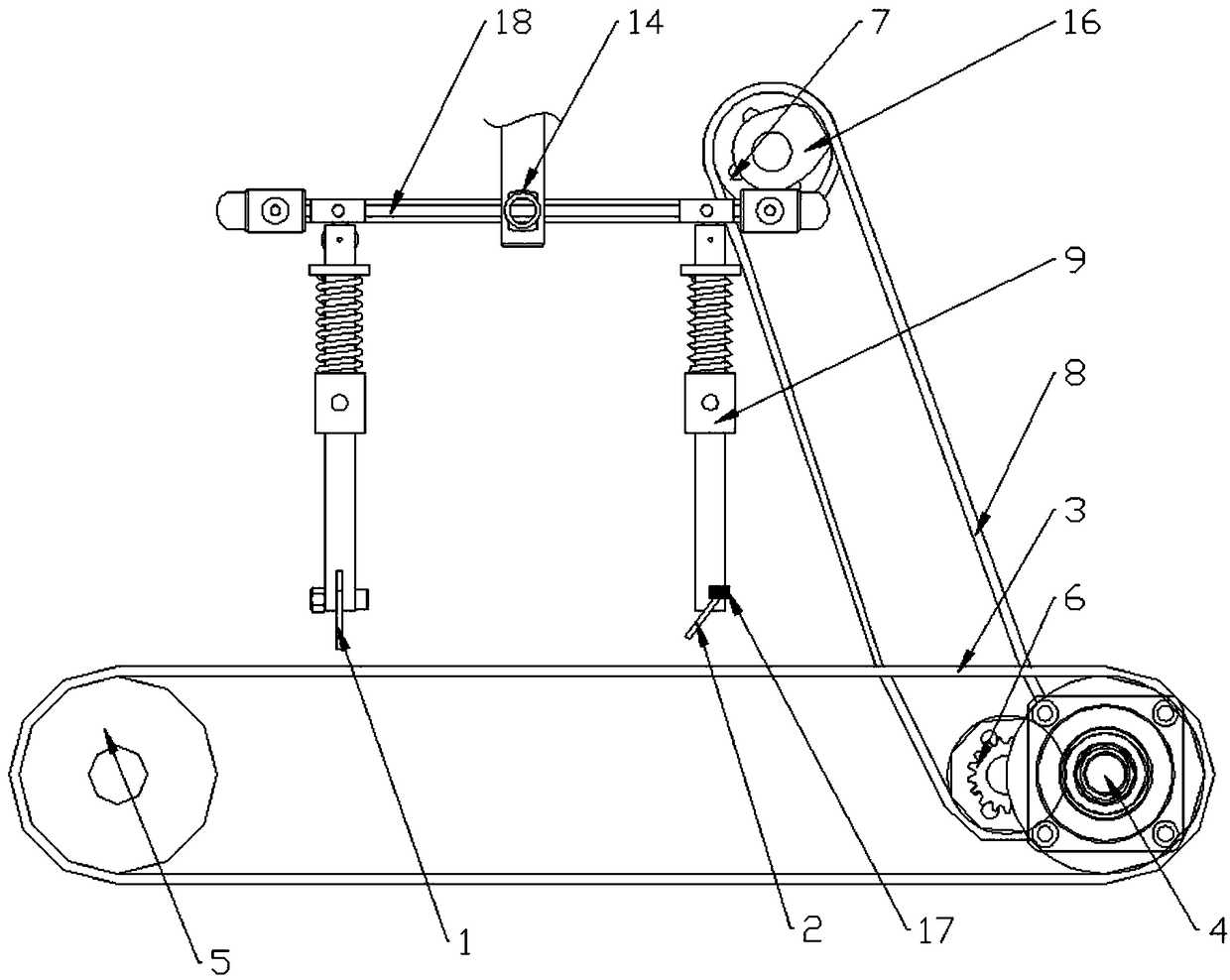

[0027] Equipment working mechanism:

[0028] The drive motor 4 is started, driven by the transmission gear 6 to drive the pulley 5, and the pulley drives the conveyor belt 3 to rotate to transport the workpiece.

[0029] The driving transmission wheel on the left side of the transmission gear 6 realizes the driving of the driven transmission wheel 7 through the transmission belt 8, so that the final shaft 16 rotates,

[0030] The pressing shaft 16 is an elliptical pressing roller. During the rotation of the pressing shaft 16, since it is in contact with the top surface of the transmission connecting rod 18, when the long diameter of the ellipse is in contact with the transmission connecting rod 18, will push it down,

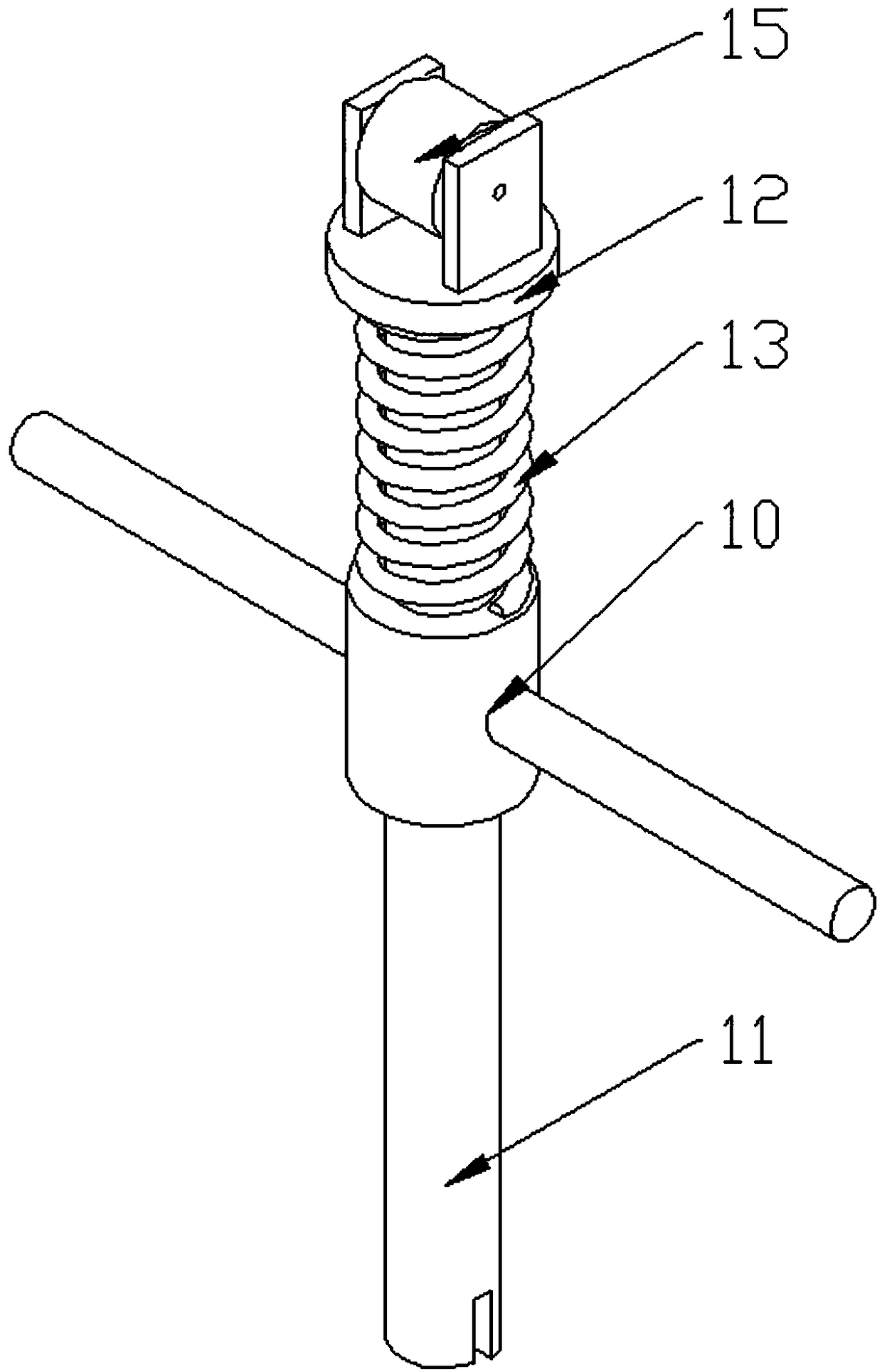

[0031] During the pressing down process, the pressure roller 15 will roll along the bottom surface of the transmission connecting rod 18, and drive the guide rod 11 to move downward, and move downward together with the oblique cutter 2 to realize the oblique cu...

Embodiment 2

[0035] For the adjustment of cutting parameters:

[0036] During the cutting process, it is necessary to adjust the cutting slope, cutting distance, cutting depth, and the length of the top surface of each bevel tooth. This adjustment is realized by adjusting different components in the equipment.

[0037] Although the adjustment of the wheel diameter of the pulley 5 can realize the adjustment of the conveying speed of the conveyor belt when other variables are constant, in order to ensure the complete installation of the equipment and the convenient adjustment, such major changes as the replacement of the pulley 5 are not carried out. adjust.

[0038] Adjusting the depth at which the vertical cutter 1 is embedded in the guide rod 11 can adjust the cutting depth of the vertical cutter 1,

[0039] Adjusting the height at which the guide rod 11 is embedded in the notch can realize the adjustment of the cutting depth of the oblique cutter 2,

[0040] By adjusting the angle of i...

Embodiment 3

[0044] Installation of auxiliary equipment:

[0045] The operation mechanism described in embodiment 1 is the basic operation mechanism, if more functional improvements are needed, the equipment can be refitted,

[0046] A clutch assembly is installed between the transmission drying 18 and the final shaft 16, which can realize the separation of the conveyor belt 3 transportation and cutting, thereby ensuring the control of workpiece movement and loading during cutting, and improving the cutting effect.

[0047] The transmission of the transmission belt 7 can be cancelled, and the workpiece transportation and cutting can be respectively realized by two motors. At this time, the cutting parameters can also be adjusted by the motor speed, which simplifies the adjustment steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com