Paperboard cutting device

A cutting device, cardboard technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve problems such as accidents, inaccurate cutting positions, and inability to be moved to accurate positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

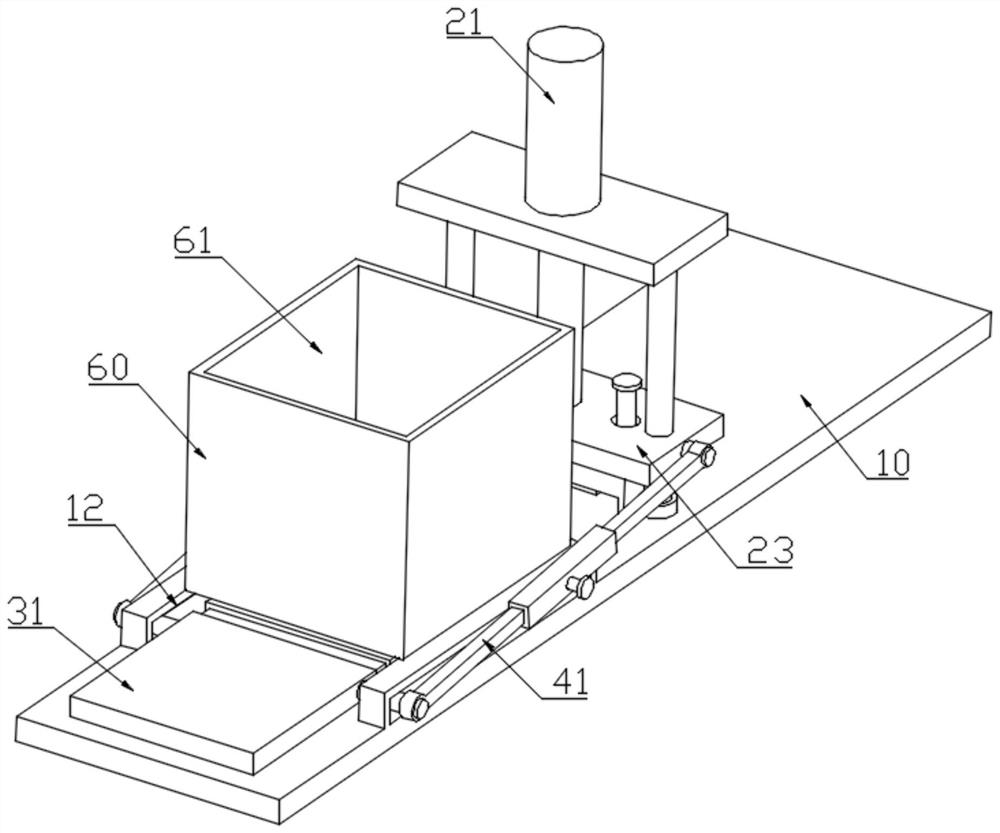

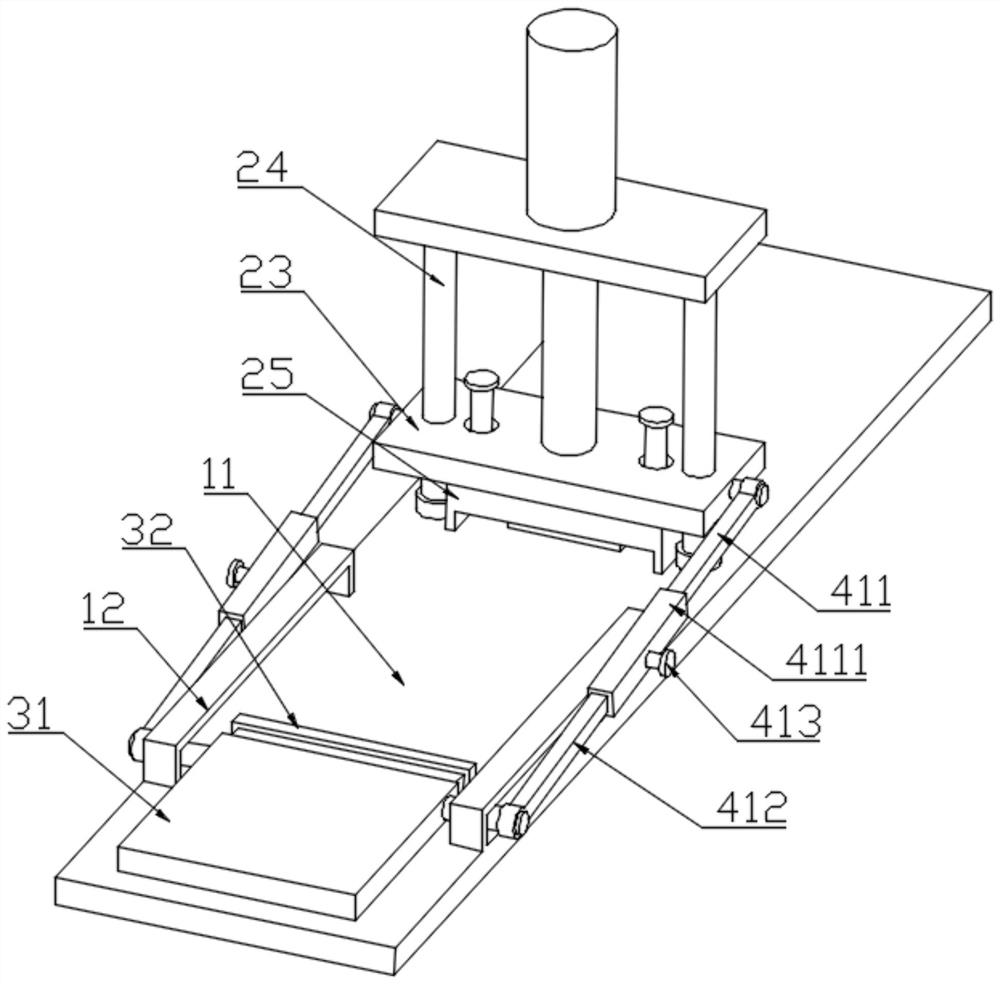

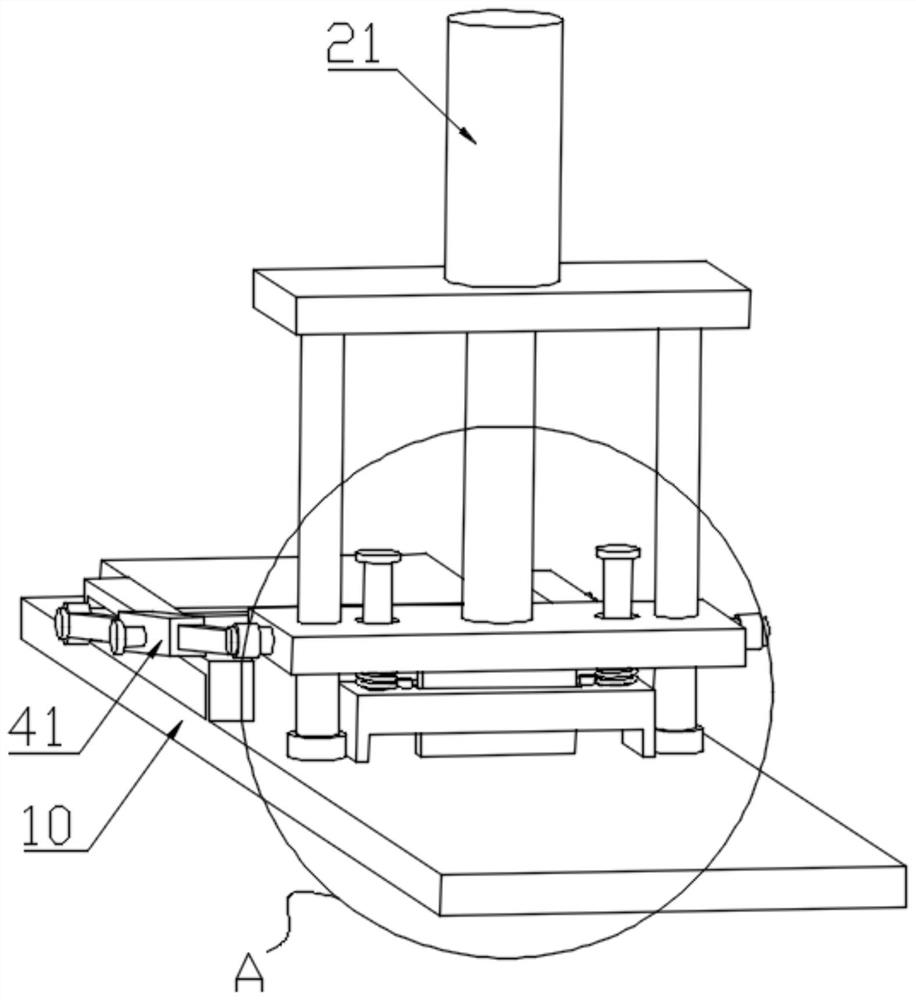

[0038] see Figure 1 to Figure 4 , a cardboard cutting device in this embodiment includes a conveying platform 10, a cutting assembly, a pushing assembly, a linkage assembly, and a storage box 60;

[0039] Specifically, the first end of the conveying platform 10 is provided with an accommodating space 11 for placing the cardboard;

[0040] Specifically, the cutting assembly is provided on the conveying platform 10; the cutting assembly includes a power source 21 and a knife die 22, and the power source 21 can drive the knife mold 22 to move vertically; the power source 21 is preferably a cylinder;

[0041] Specifically, the pushing assembly is disposed at the first end of the conveying platform 10, and the accommodating space 11 is located between the pushing assembly and the cutting assembly; the pushing assembly is used to push the cardboard on the accommodating space 11 to the cutting assembly below;

[0042] Specifically, the linkage assembly connects the cutting assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com