Patents

Literature

41results about How to "Uniform cutting length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beard trimmer

InactiveUS20180085945A1Improve abilitiesEase of use and comfortMetal working apparatusEngineeringMechanical engineering

Owner:BRAUN GMBH

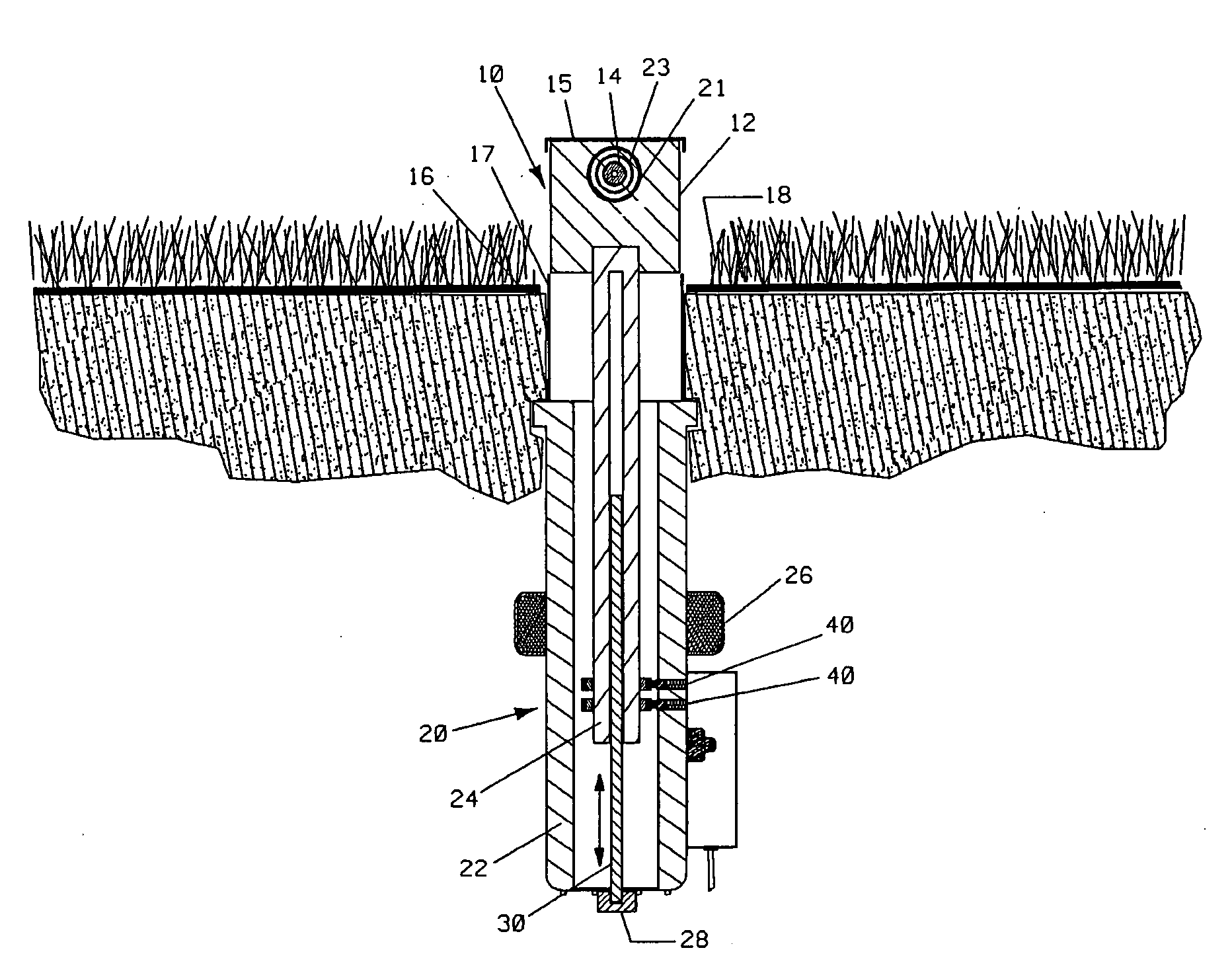

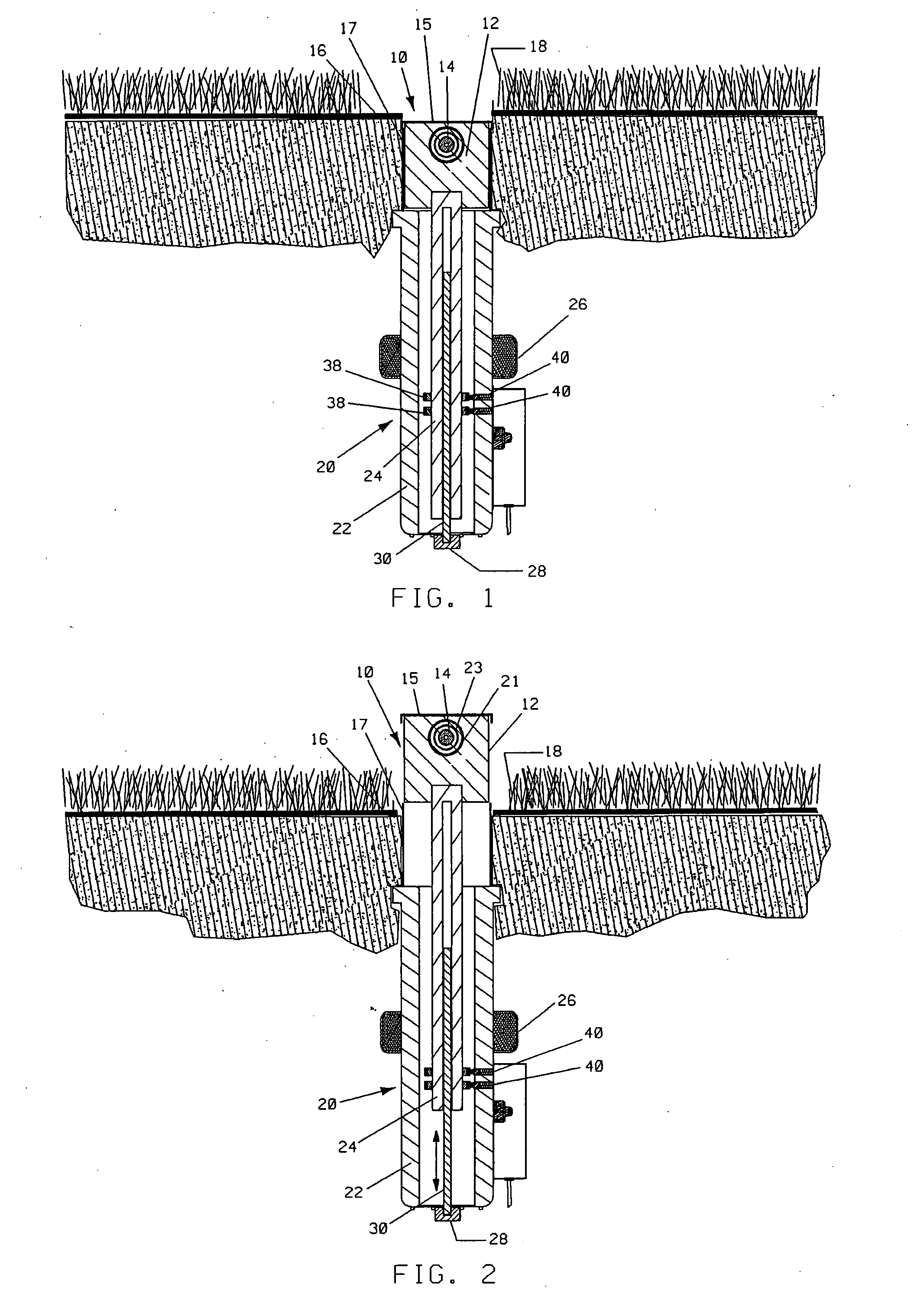

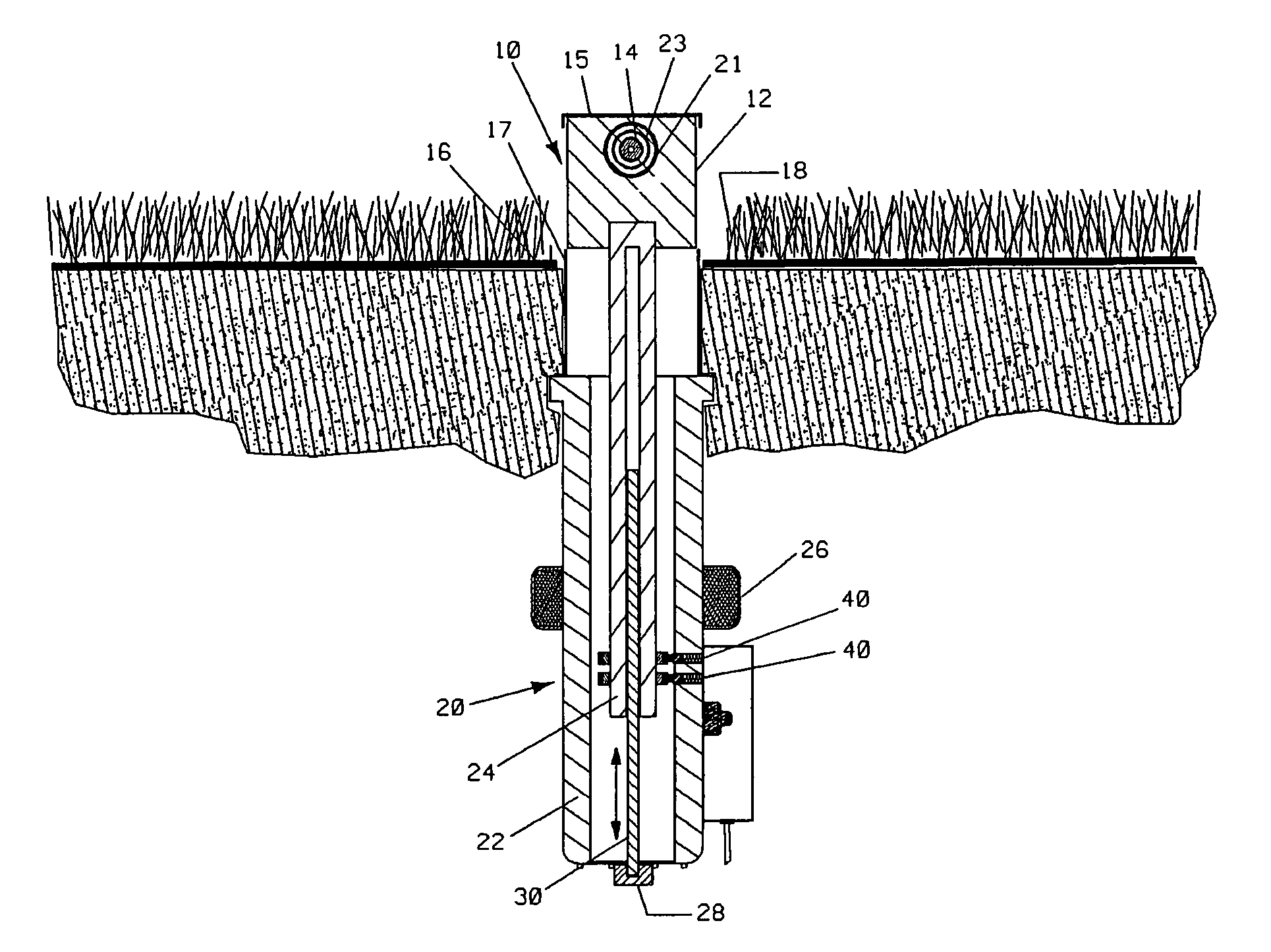

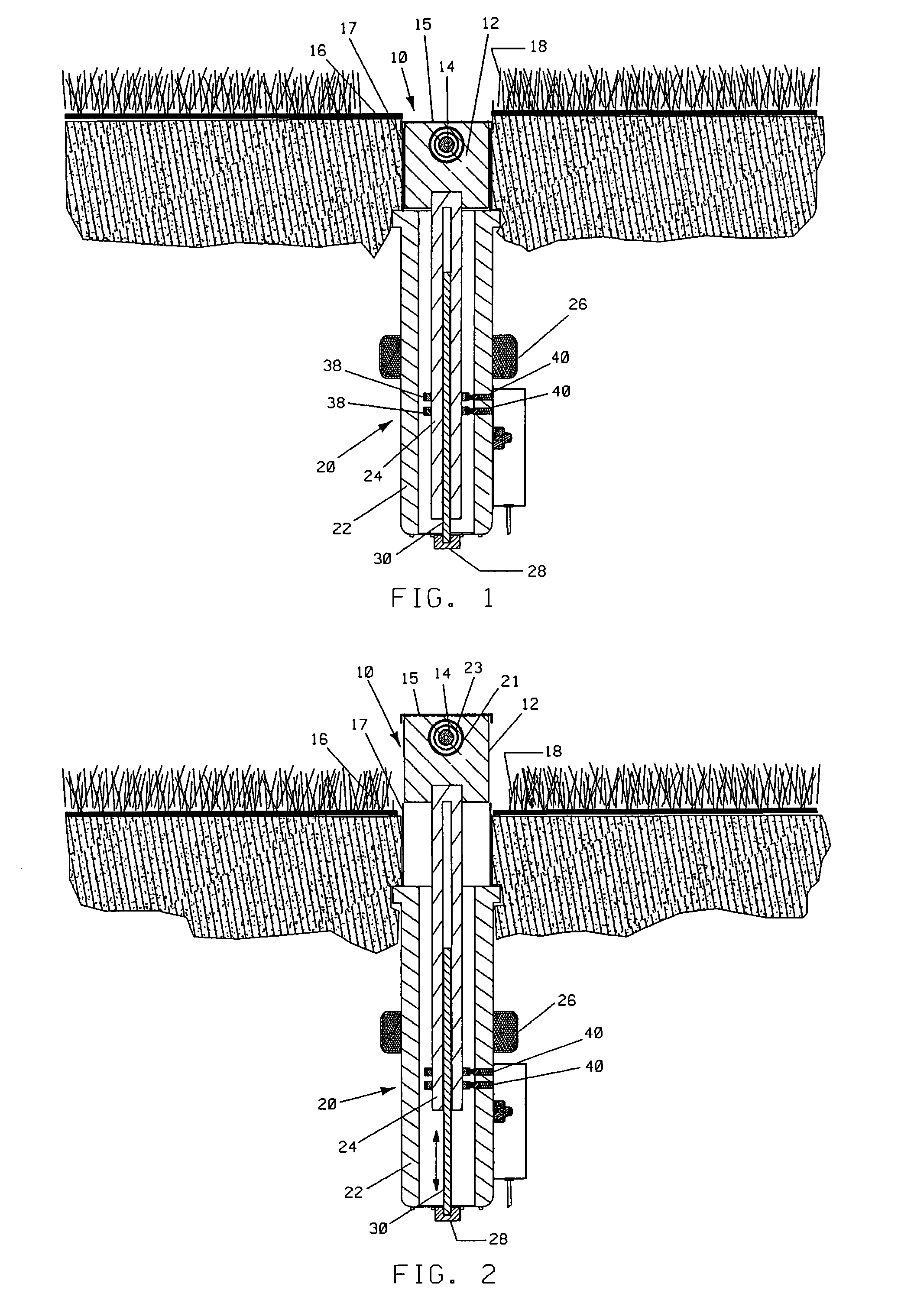

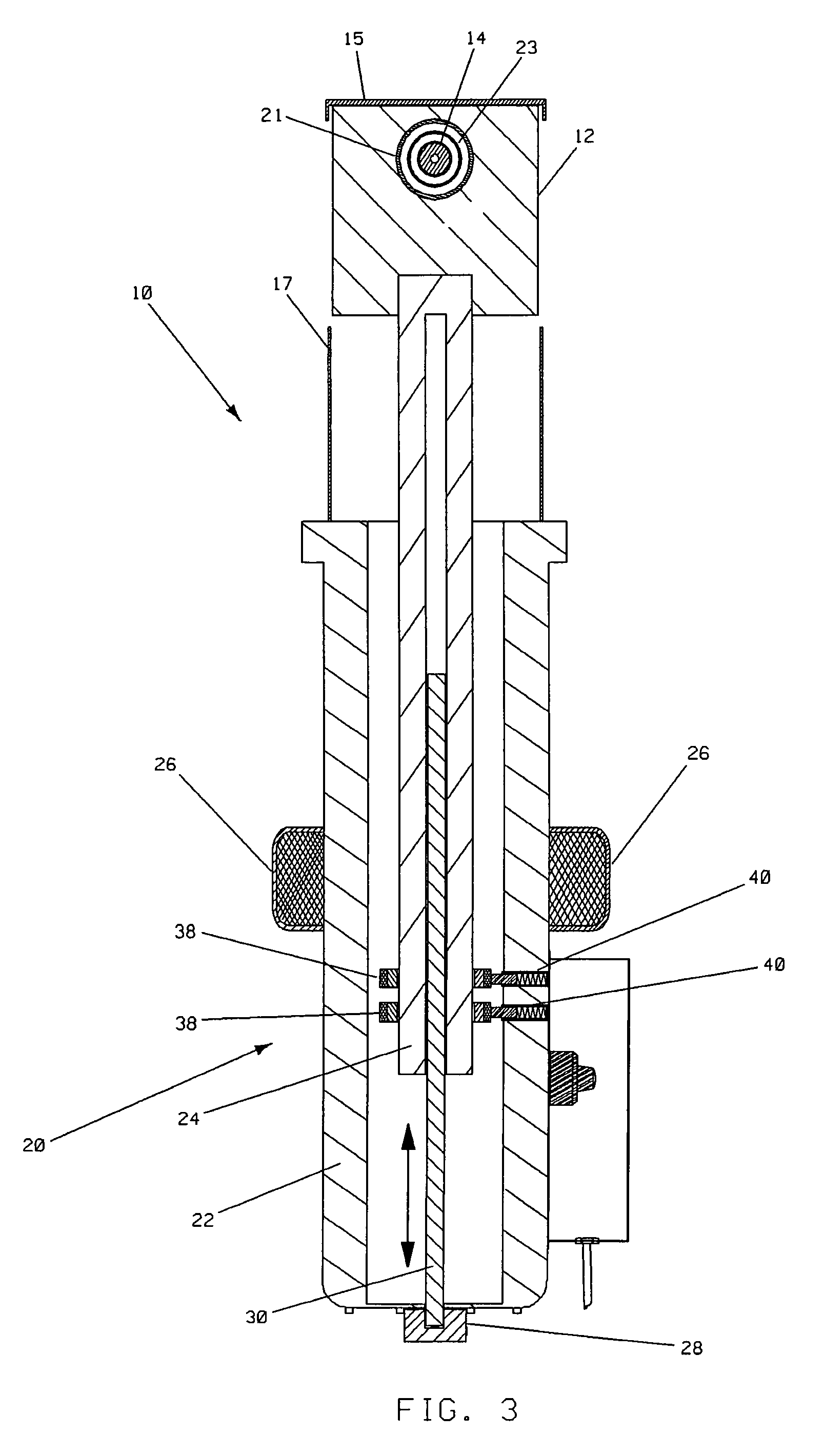

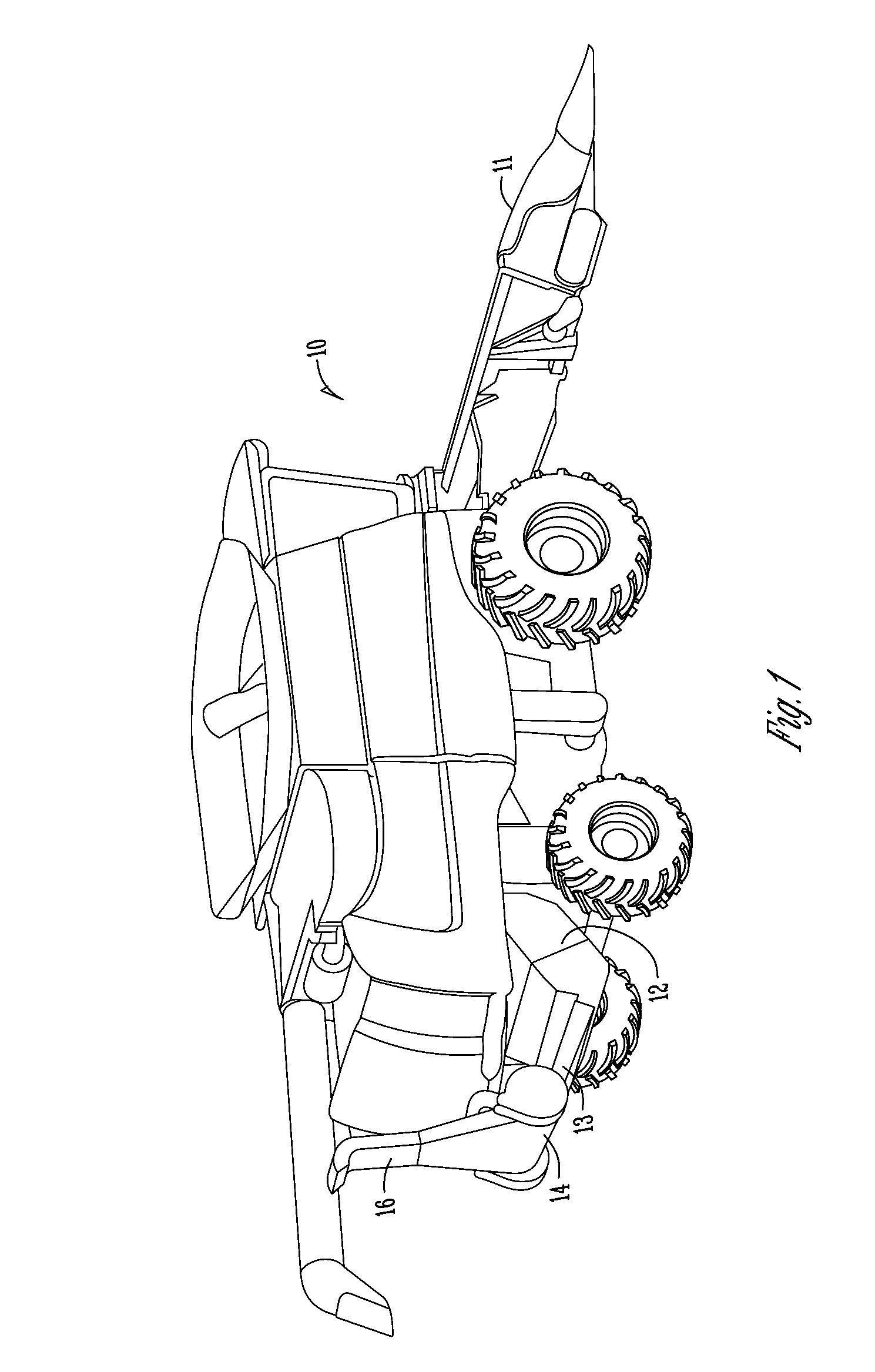

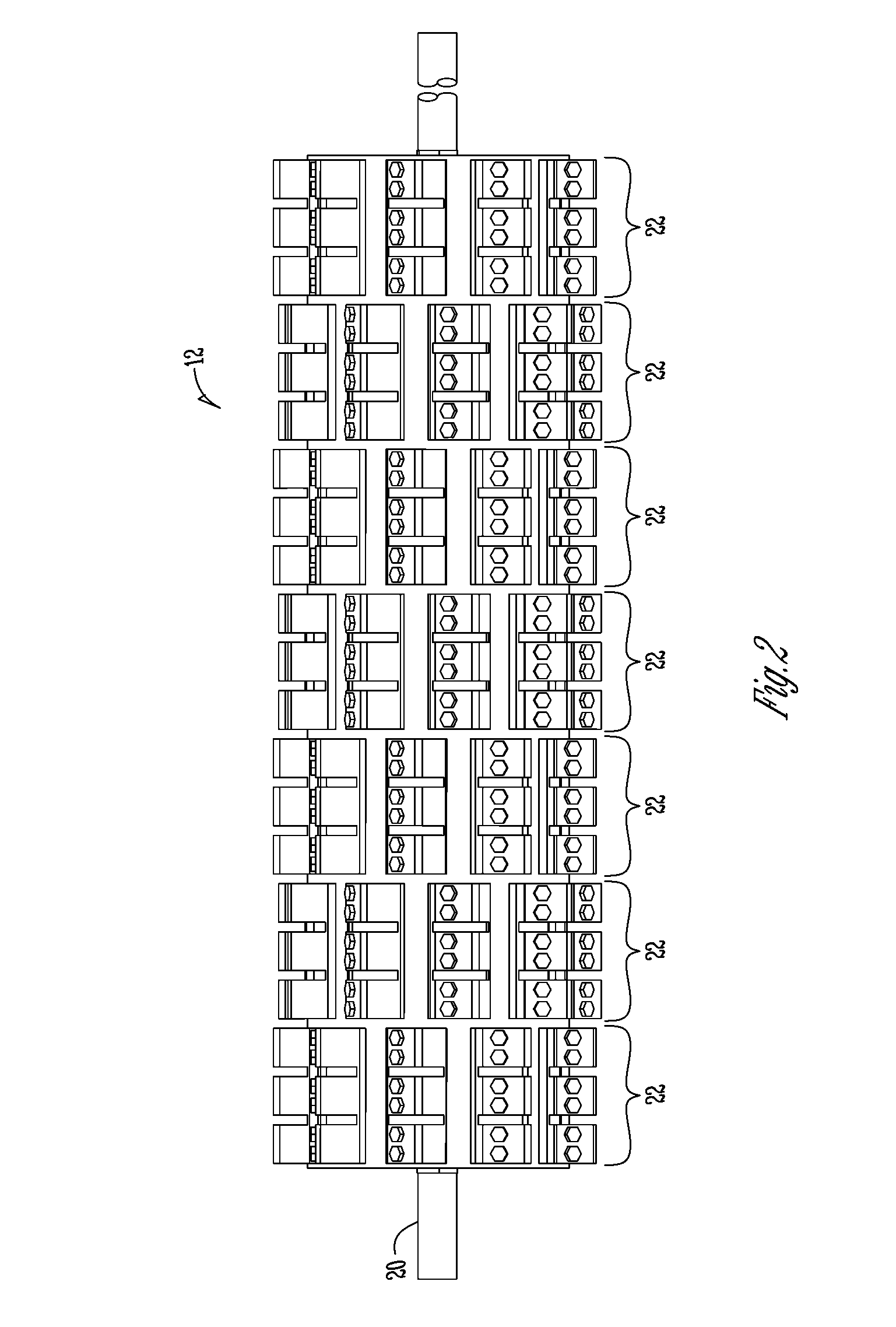

Apparatus and method for cutting lawns using lasers

InactiveUS20080244970A1Overcome problemsUniform cutting lengthRoot feedersCrop conditionersMarine engineeringLaser light

The laser lawn cutting system of the present invention consists of an array or grid of laser heads distributed across a lawn. The laser heads may be permanently fixed above the surface of the lawn, or preferably mounted underneath the surface of the lawn and designed to pop up at the time of cutting. If mounted underneath the surface of the lawn, solenoids may be used to move the laser heads above the surface. Other mechanical devices could also be used to cause the laser heads to move above the surface of the lawn. Preferably, the laser heads will be distributed across the lawn in a grid or matrix, such that the laser light generated by the rotating laser head sweeps across the lawn in overlapping arcs to cut the vegetation. The system may also be used to melt snow or kill insects.

Owner:RENEWABLE THERMODYNAMICS LLC

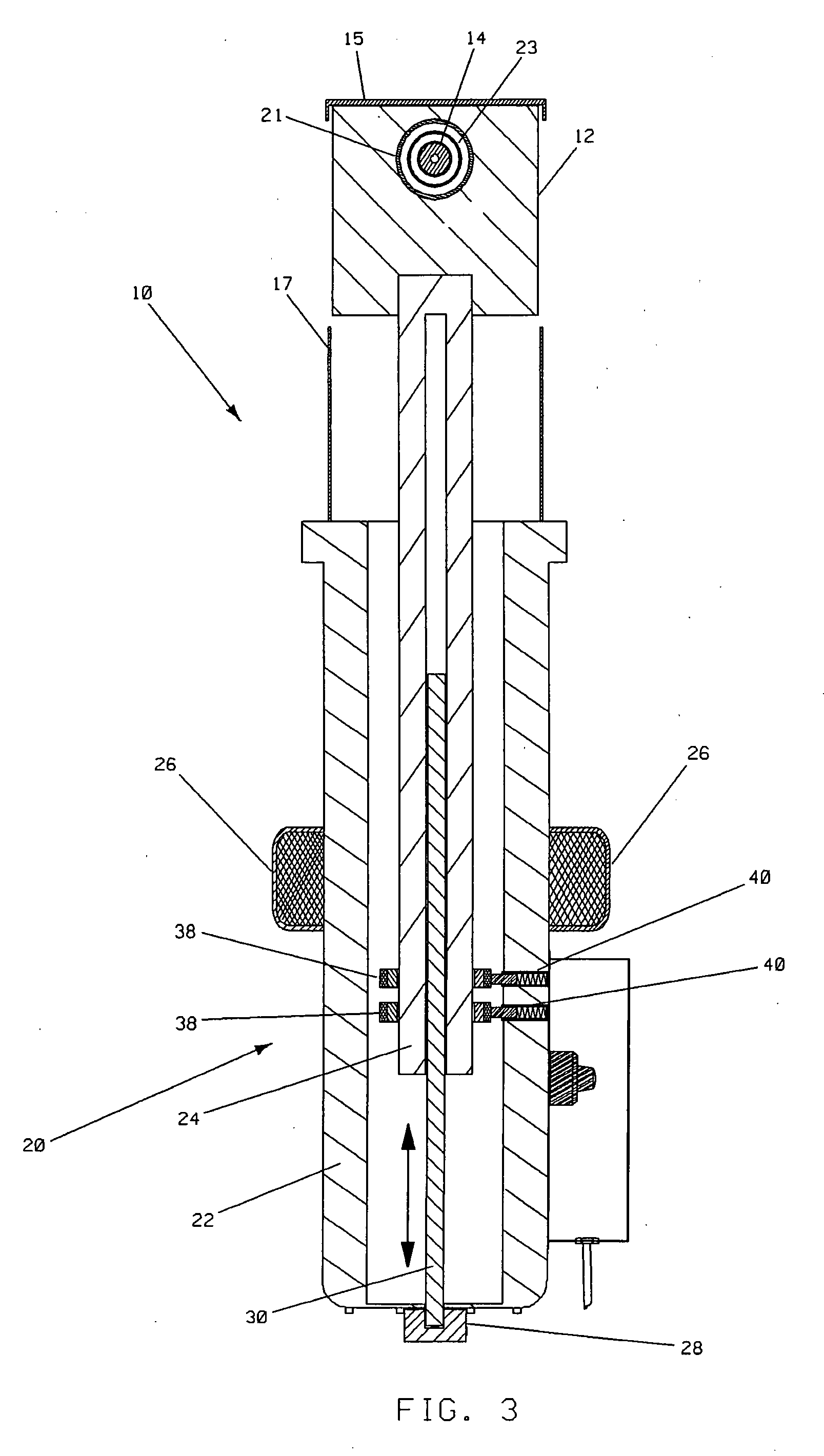

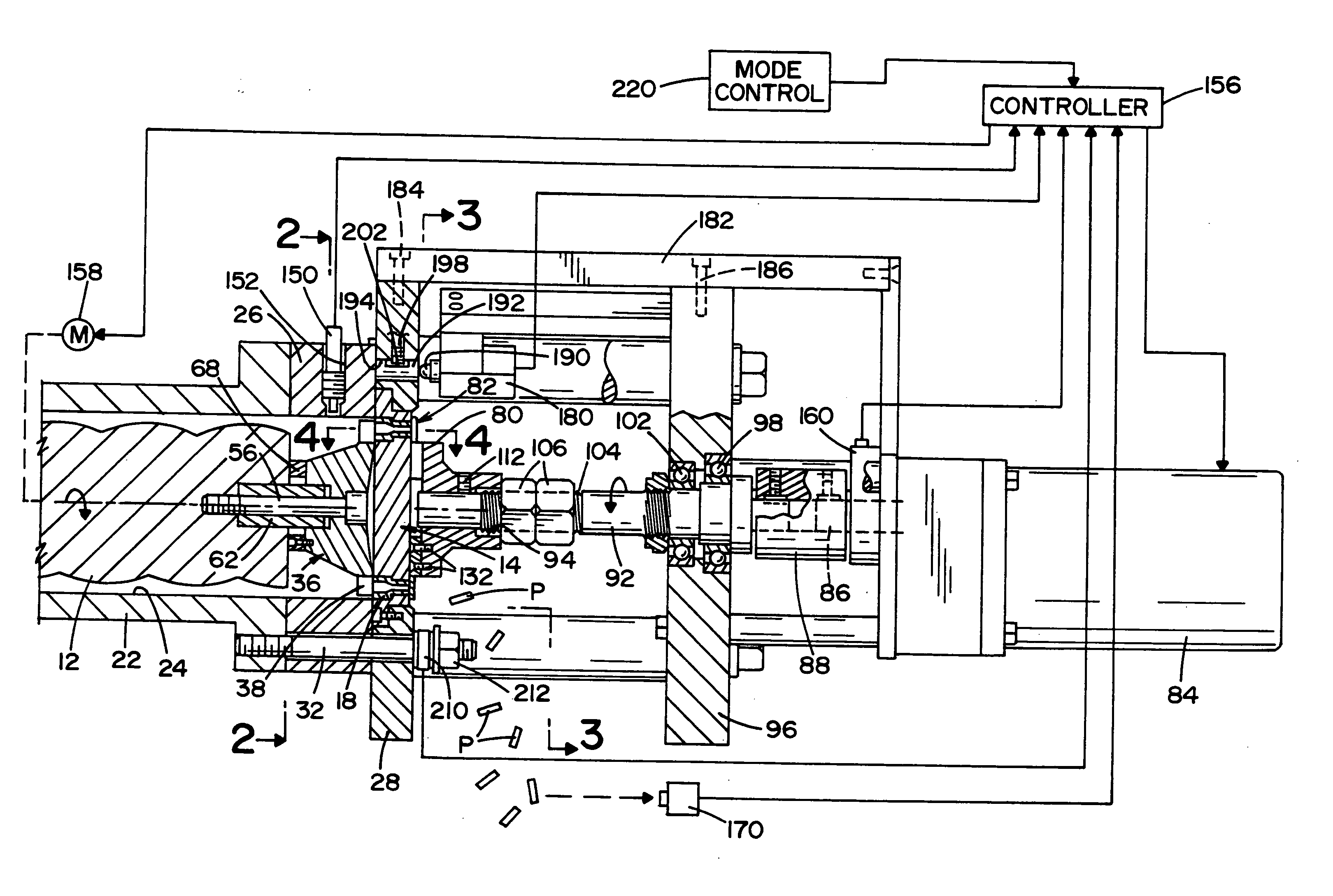

Pulse wave modulator cutting assembly

ActiveUS20070259067A1Increase the number ofReduce throughputMouldsFrozen sweetsEngineeringPulsed wave

A cutting assembly for cutting a material extruded from a die can include a wiper adapted to connect to an auger or a rotating member, a die holder plate disposed adjacent the wiper, a cutter member disposed downstream from the die holder plate, and a pressure sensor.

Owner:JMP INDS

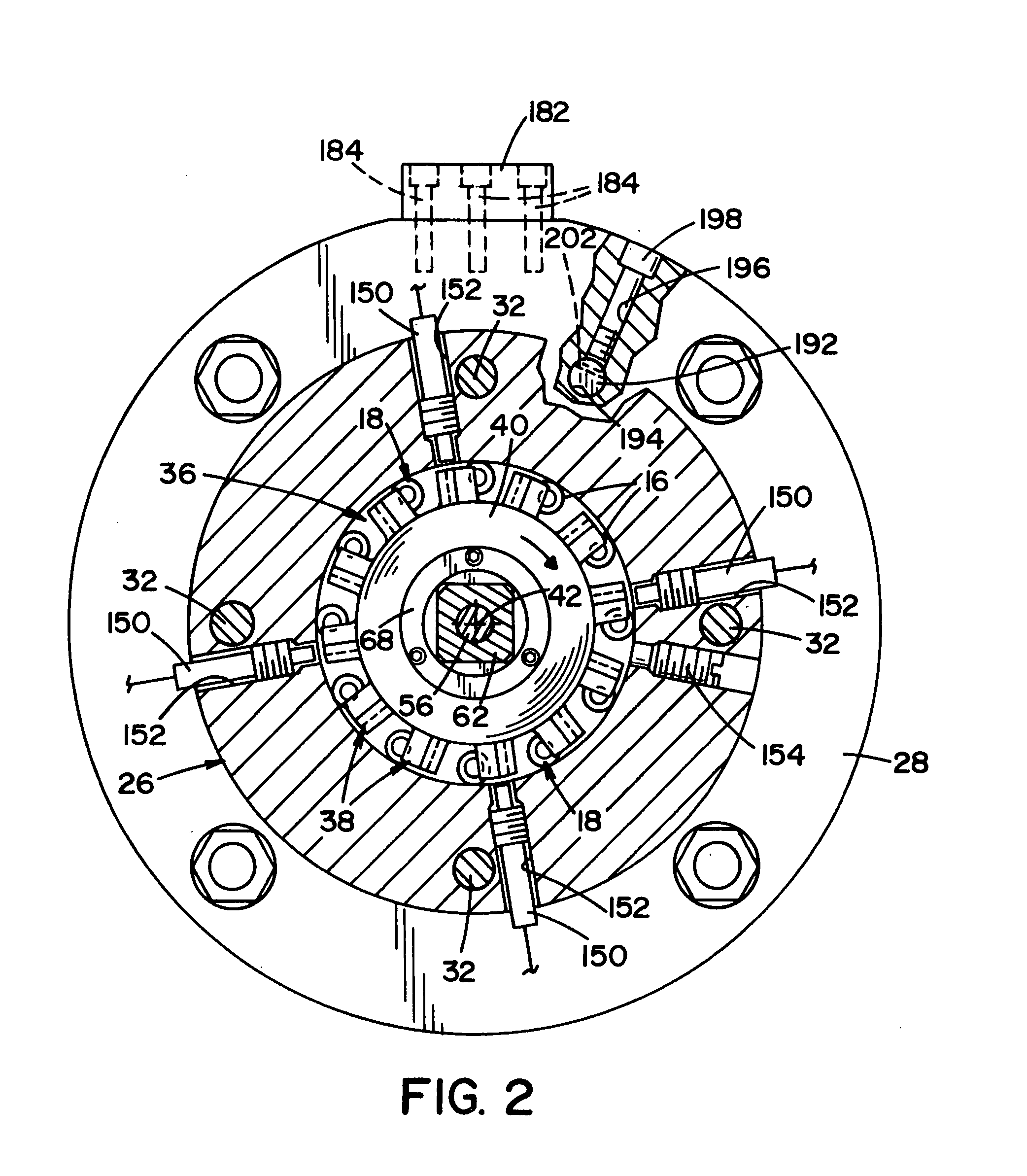

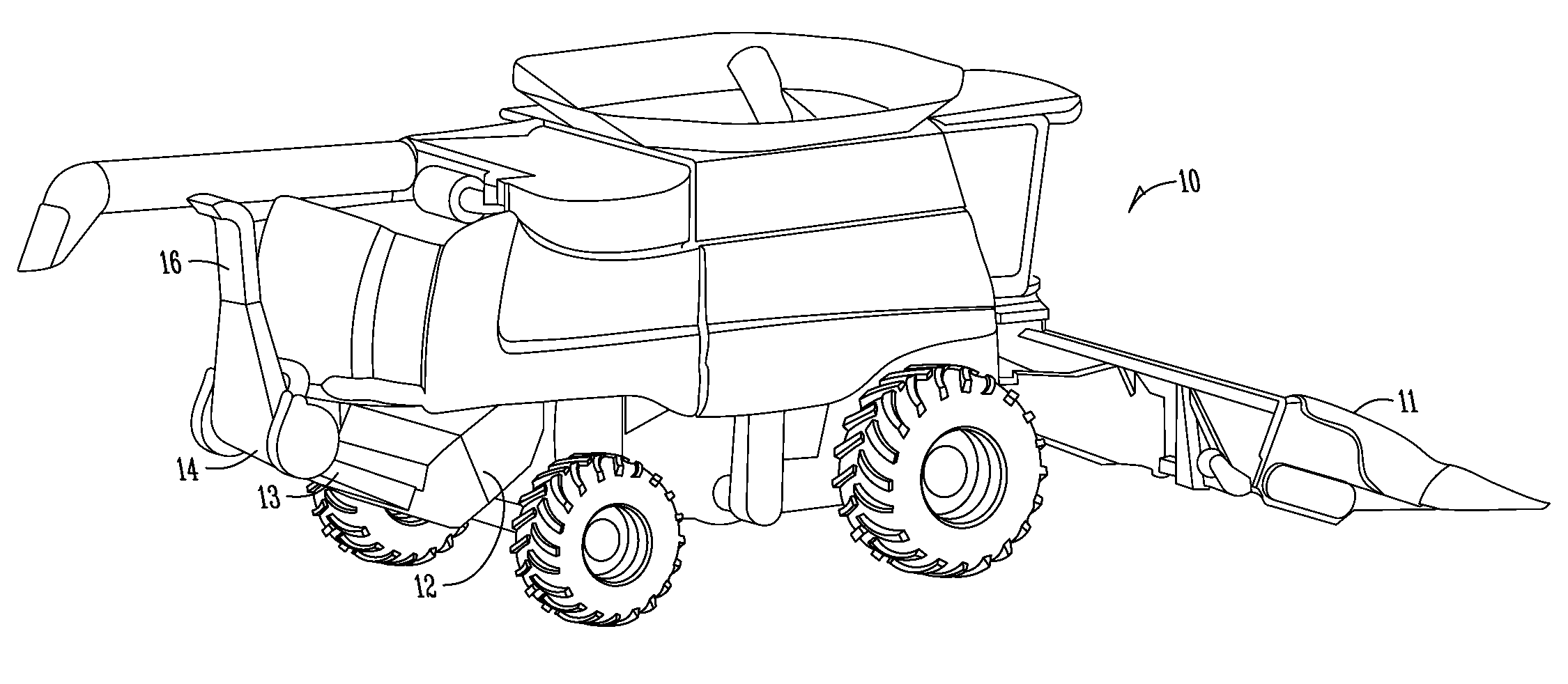

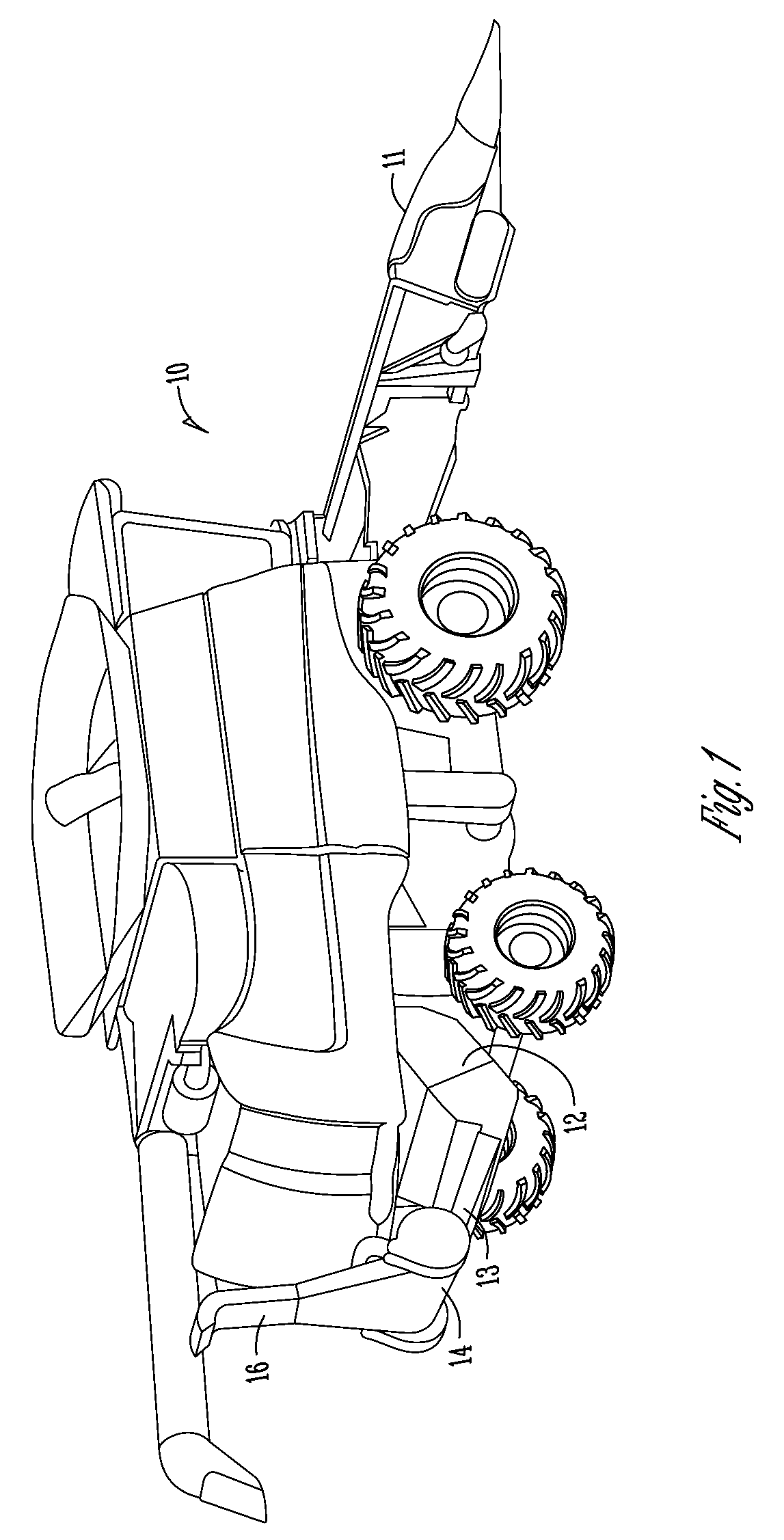

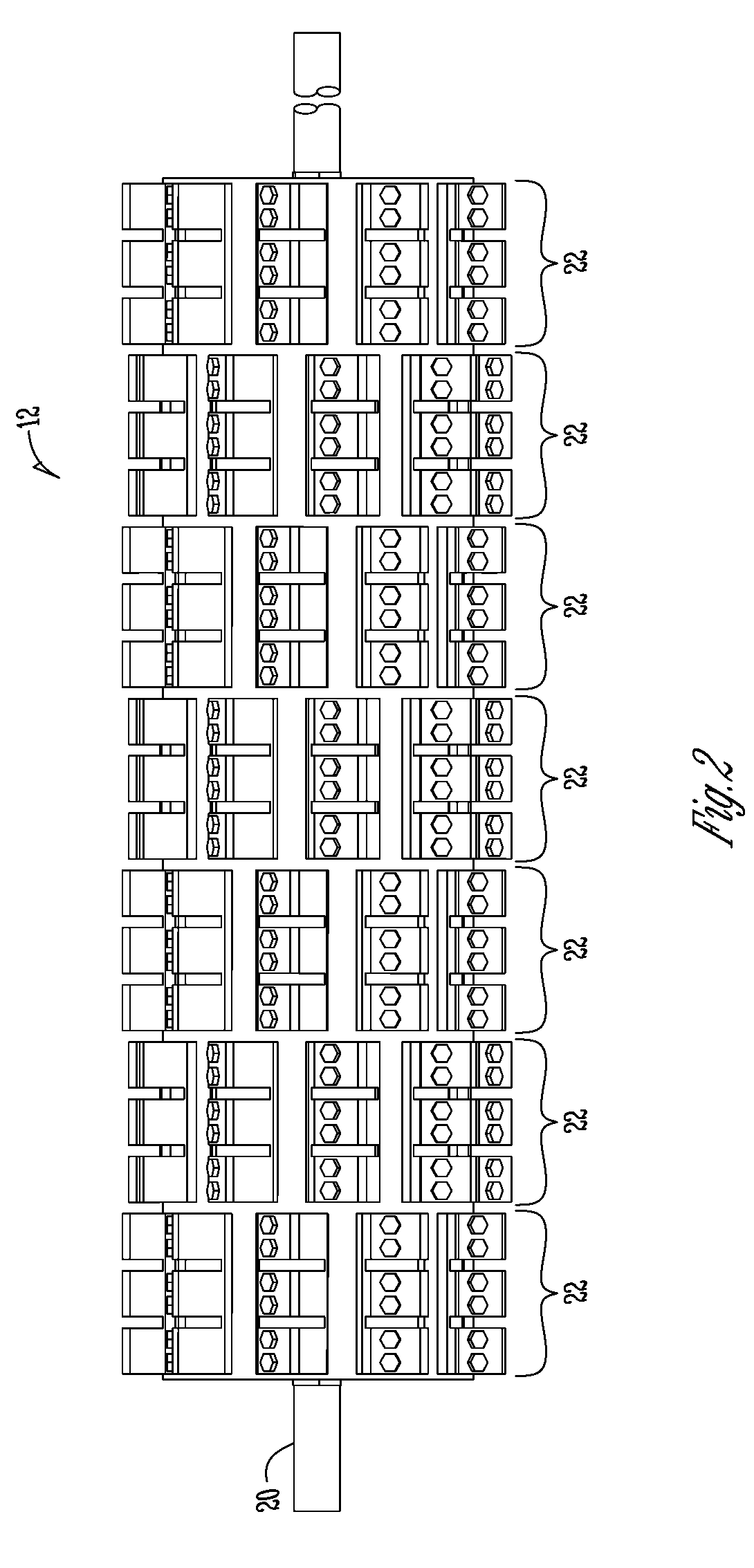

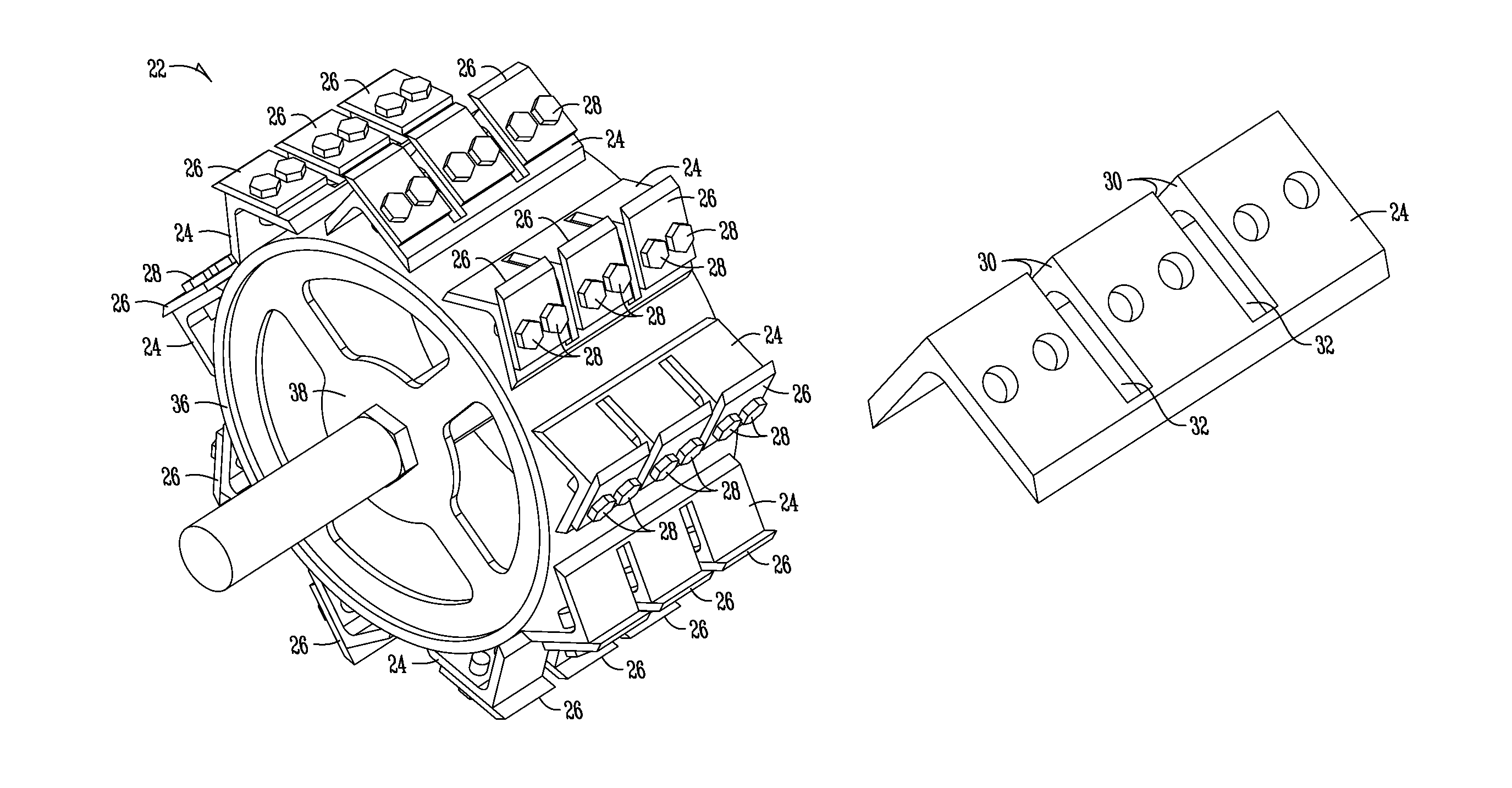

Double shear material chopper

InactiveUS20080268928A1Uniform cutting lengthReduced Power RequirementsMowersCuttersEngineeringCombine harvester

A material chopper for chopping a material is provided. The double shear chopper may include a counter shear bar, a plurality of stationary knives associated with the counter shear bar, a shaft, at least one rotor section operatively connected to the shaft, each of the at least one rotor section configured to rotate with the shaft, at least one knife holder in each of the at least one rotor section, at least one knife operatively connected to each of the at least one knife holder, and slots in each of the at least one knife holder, wherein edges of the slot provide counter shear surfaces for the plurality of stationary knives. The material chopper may be added to or incorporated into a harvesting machine such as a combine.

Owner:IOWA STATE UNIV RES FOUND

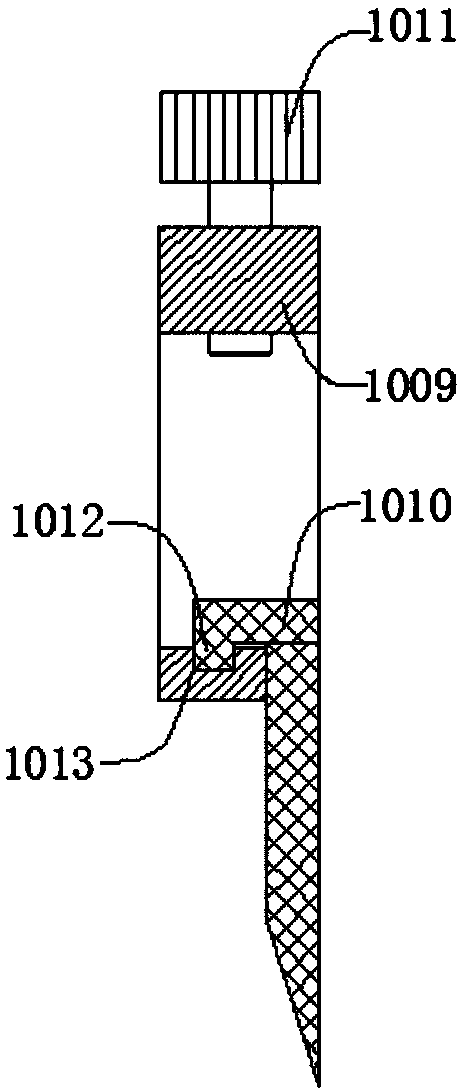

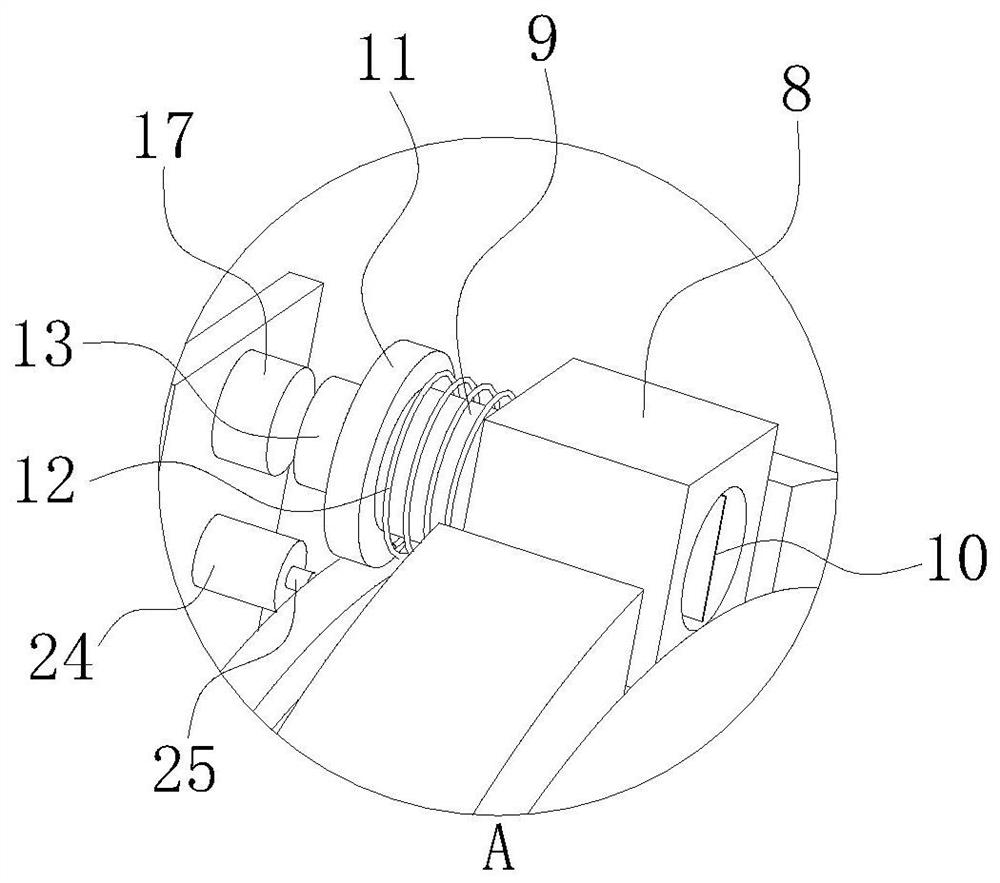

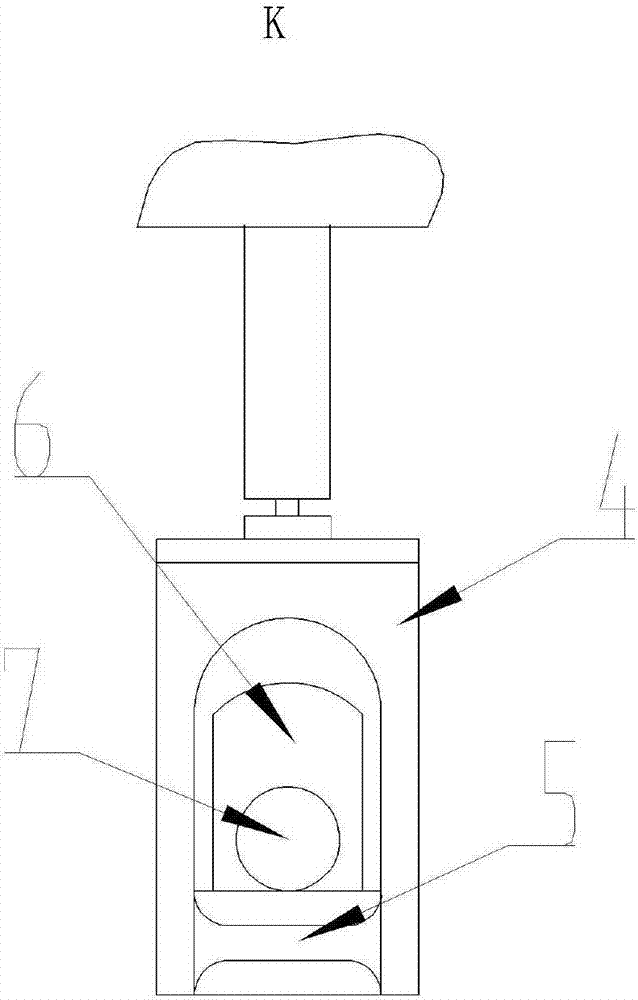

Adjustable cutting knife

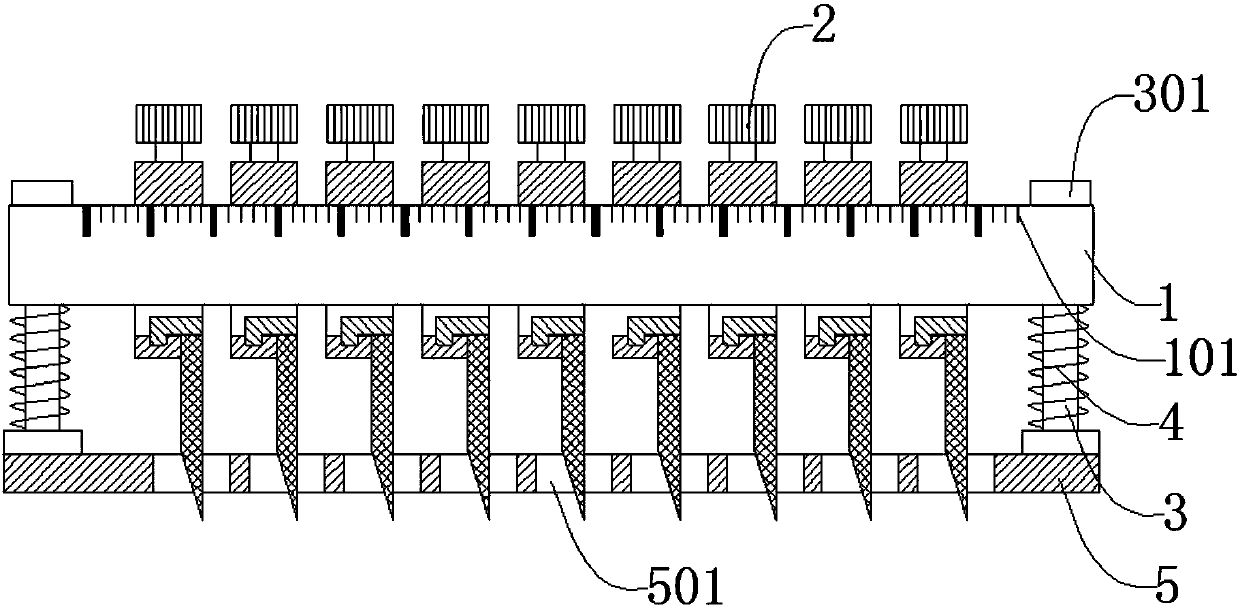

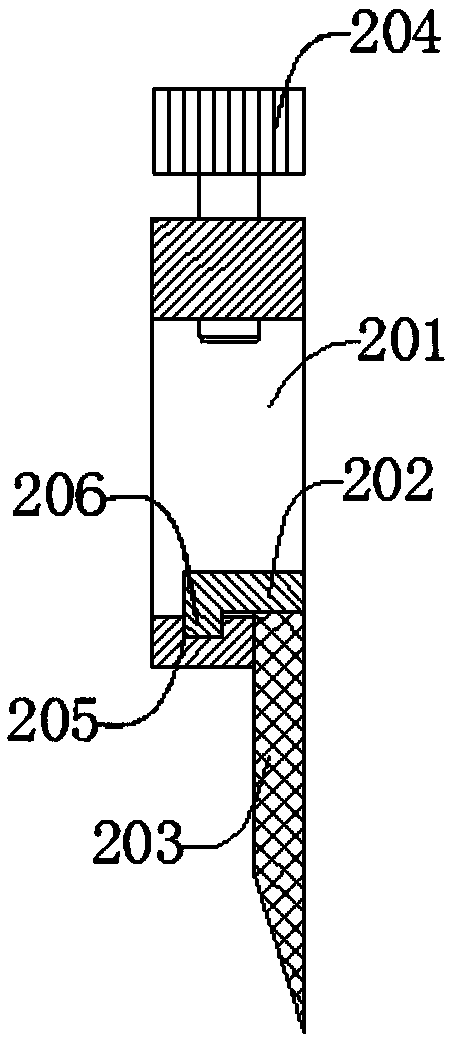

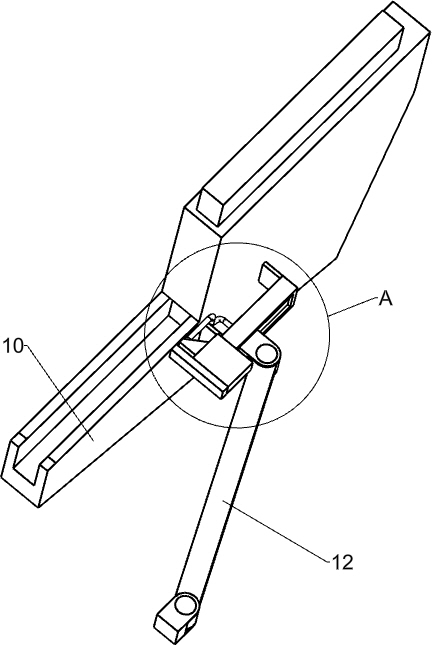

PendingCN107932575APrevent movementAdjustable cutting lengthMetal working apparatusEngineeringSlide plate

The invention discloses an adjustable cutting knife, which comprises a sliding plate, a knife mechanism, a guide rod, a spring, and a pressure plate. The adjustment screw is loosened, and the distance between the knife mechanisms is manually adjusted. The distance between the two cutter mechanisms can be intuitively obtained. When the set distance is reached, just lock the adjusting screw. When working, connect the device with the driving mechanism. When the driving mechanism operates, the pressing plate first contacts the material to be cut. With the further action of the driving mechanism, the spring is compressed, the sliding plate moves down along the guide rod, and the cutter passes through the pressing plate The adjustment groove on the upper cuts off the material to be cut. The structure of the device is simple, not only the cutting length is uniform, but also the cutting length is adjustable. At the same time, through the pre-pressing of the over-pressing plate, the movement of the material to be cut is effectively prevented and the cutting accuracy is improved.

Owner:安徽九华峰生物科技有限公司

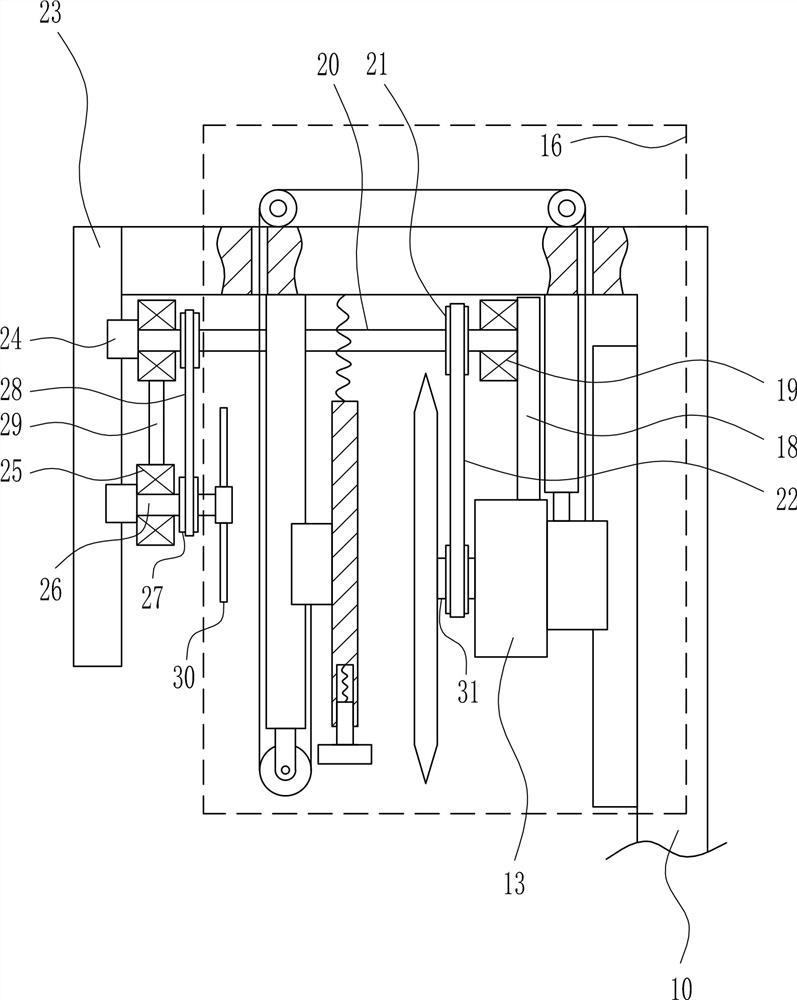

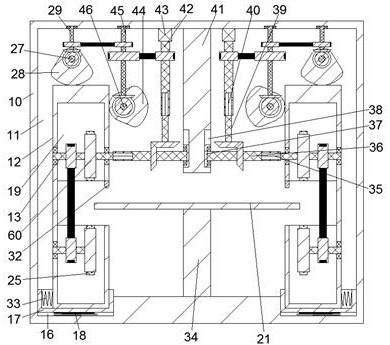

Continuous cutting-off mechanism

The invention discloses a continuous cutting-off mechanism. The continuous cutting-off mechanism comprises a bottom plate, a speed-regulating motor, a rotating shaft, a cam, a guide wheel, a connecting plate, first guiding rods, a guiding block, a C-shaped frame, a cutting-off mechanism body and first springs. The speed-regulating motor drives the cam through the rotating shaft to rotate, and thecam pushes the guide wheel to move downwards, so that the first guiding rods move downwards along the guiding block and accordingly drive the cutting-off mechanism body fixedly connected with C-shapedframe to move downwards; at the moment, the first springs are compressed, a pressing plate makes contact with a to-be-cut material firstly and rotates continuously along with the cam, second springsare compressed, a sliding plate moves downwards along second guiding rods, and cutters penetrate through regulating grooves formed in the pressing plate to cut off the to-be-cut material; and when thecam returns, the first springs return to drive the cutting-off mechanism body to reset, and the actions are repeated till cutting-off operation is completed. The continuous cutting-off mechanism is simple in structure and can conduct cutting-off operation continuously; not only is the efficiency high, but also the cutting-off length is adjustable and uniform; and meanwhile, through pre-pressing of the pressing plate, moving of the to-be-cut material is prevented effectively, and thus the cutting-off precision is improved.

Owner:安徽九华峰生物科技有限公司

Apparatus and method for cutting lawns using lasers

InactiveUS7919723B2Overcome problemsUniform cutting lengthCrop conditionersMowersVegetationMarine engineering

The laser lawn cutting system of the present invention consists of an array or grid of laser heads distributed across a lawn. The laser heads may be permanently fixed above the surface of the lawn, or preferably mounted underneath the surface of the lawn and designed to pop up at the time of cutting. If mounted underneath the surface of the lawn, solenoids may be used to move the laser heads above the surface. Other mechanical devices could also be used to cause the laser heads to move above the surface of the lawn. Preferably, the laser heads will be distributed across the lawn in a grid or matrix, such that the laser light generated by the rotating laser head sweeps across the lawn in overlapping arcs to cut the vegetation. The system may also be used to melt snow or kill insects.

Owner:RENEWABLE THERMODYNAMICS LLC

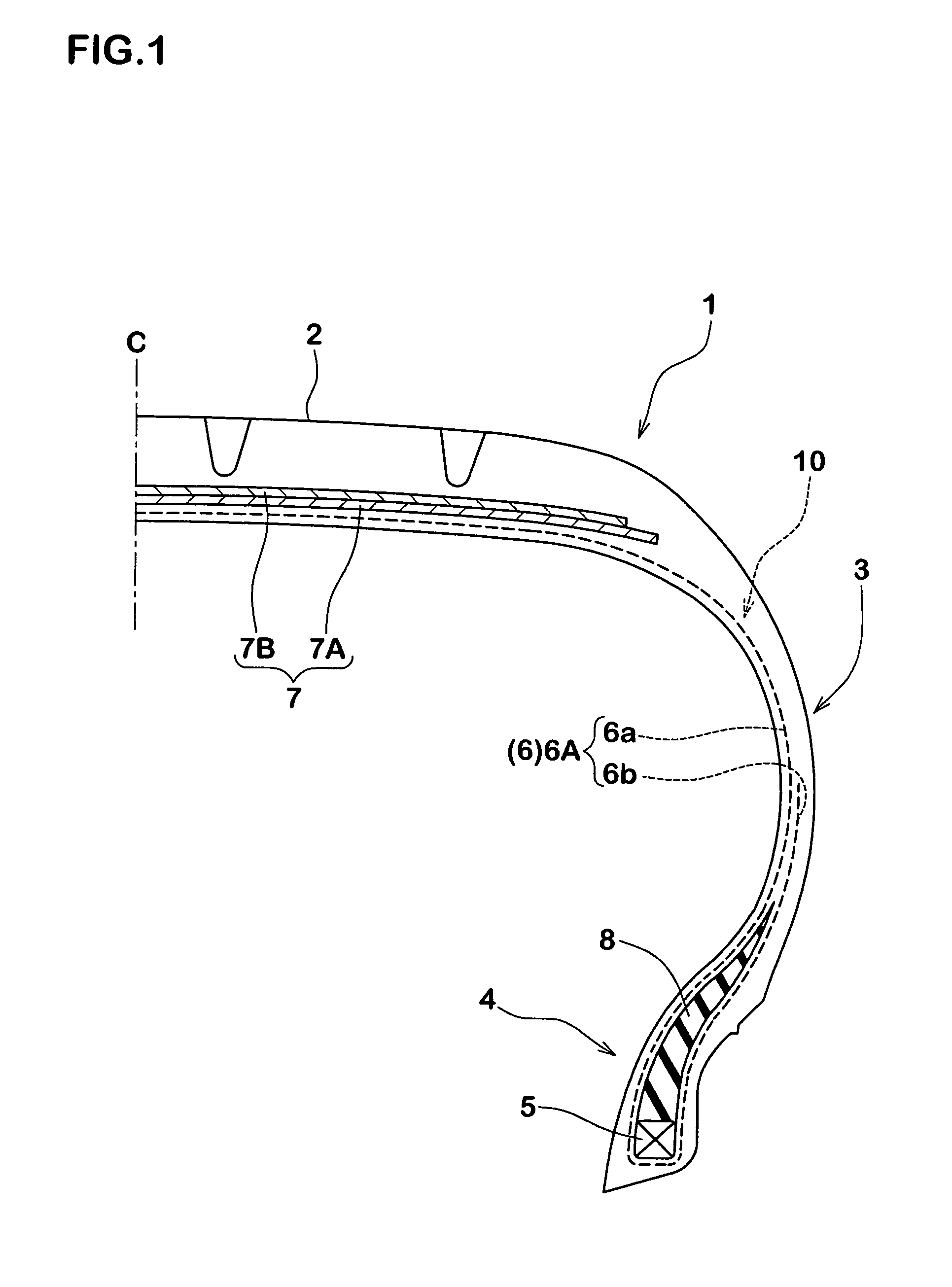

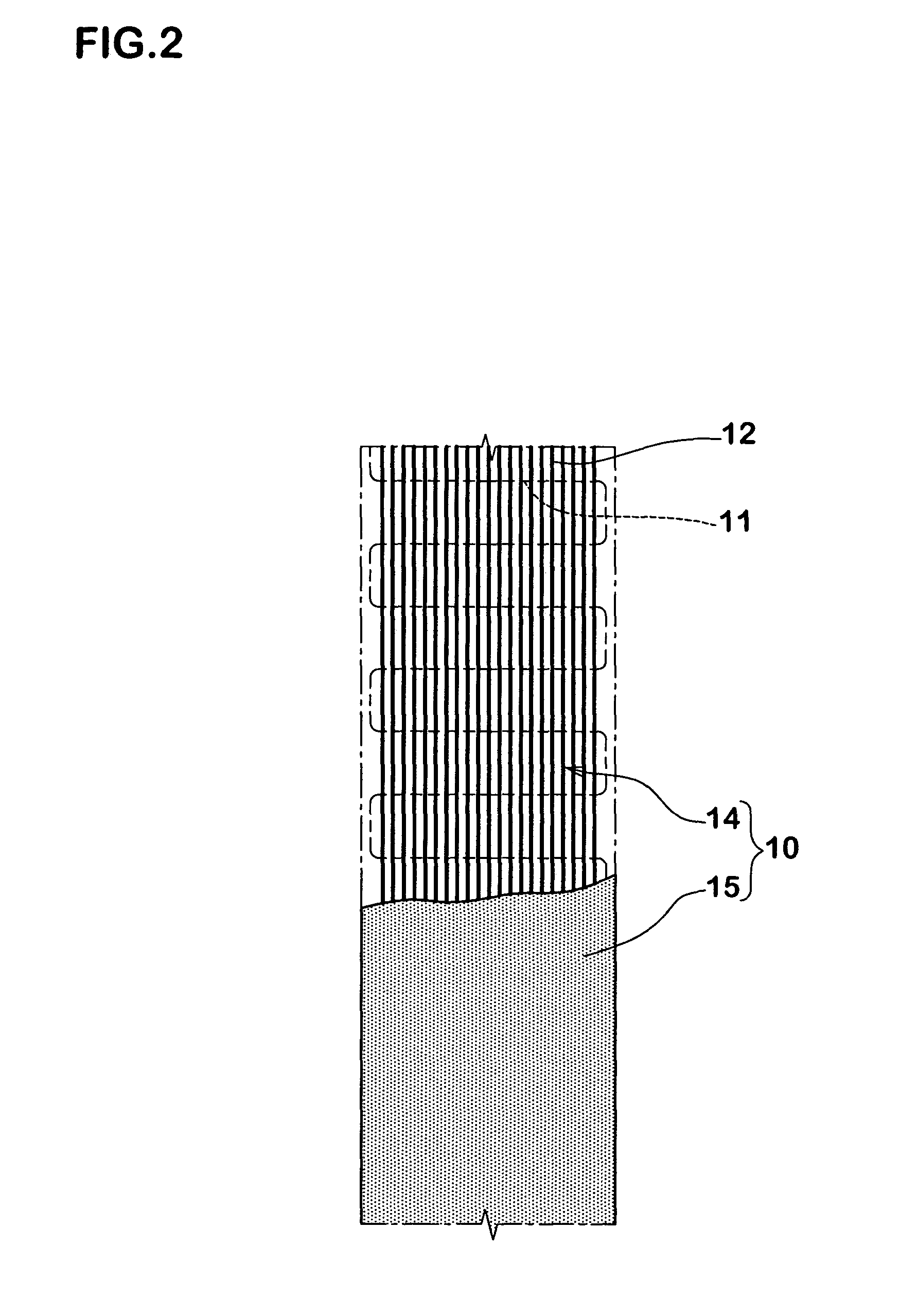

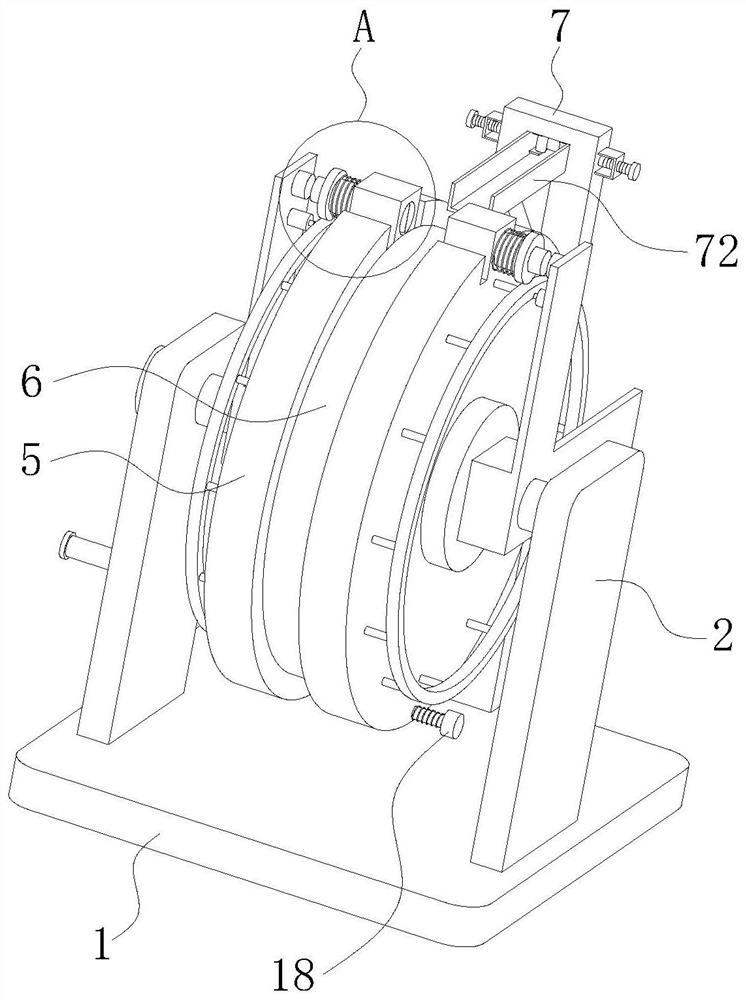

Method of manufacturing fabric with rubber for tire

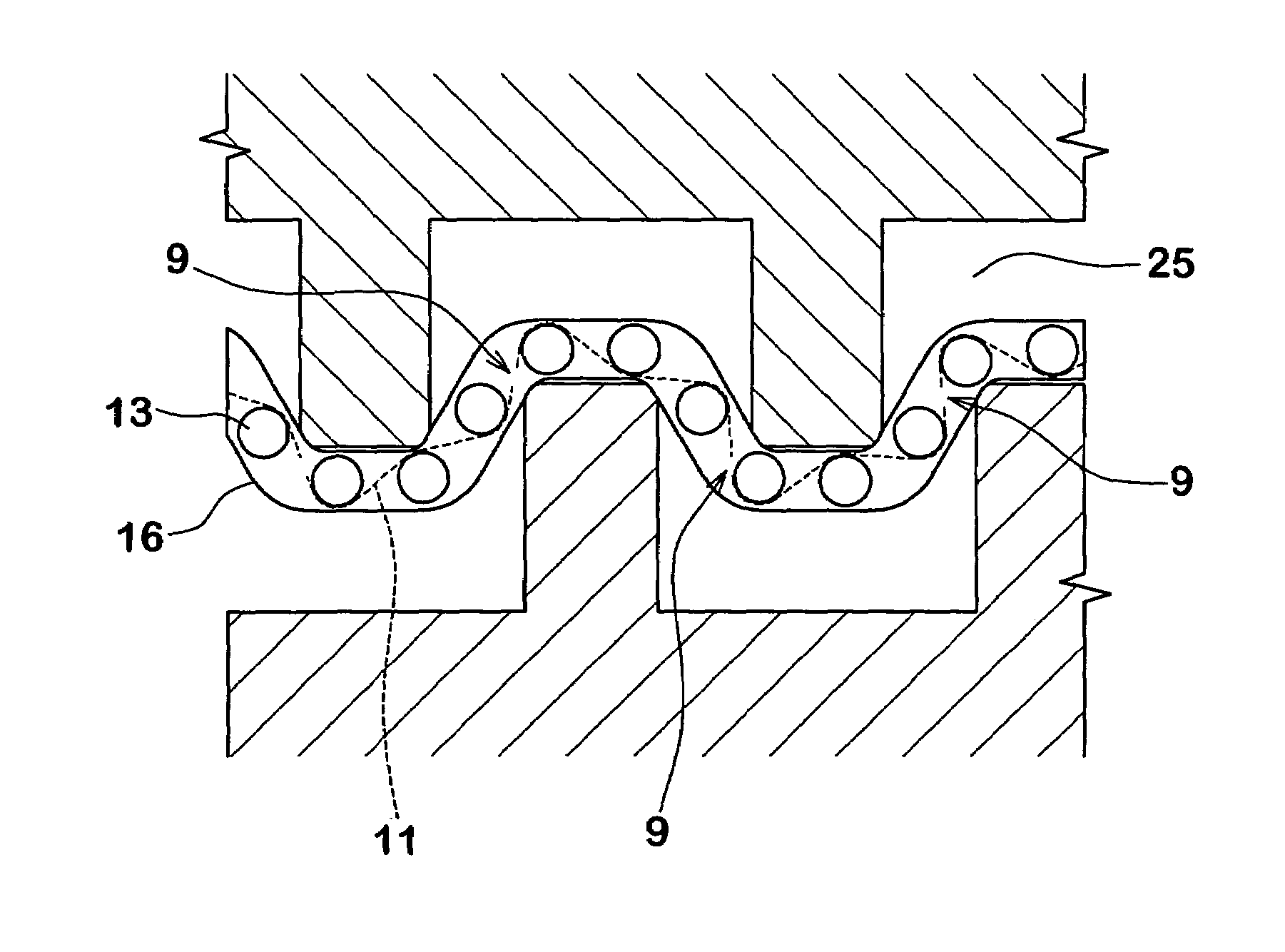

InactiveUS7115181B2Improve evenlyUniform cutting lengthLamination ancillary operationsSevering textilesGroove widthInsertion depth

A method of manufacturing a rubber coated fabric for a tire which includes a weft cutting step of cutting a weft of the rubber coated fabric base substance using a cutting device at a cut pitch Cp of two to five times an arrangement pitch P of a warp. The cut ductility of the weft is set between 5 and 20%. The cutting device utilizes first and second rollers in which the peripheral protrusions and the peripheral grooves are alternately formed. Groove widths W1 and W2 of the peripheral grooves of the first and second rollers are set between 2.0 and 5.0 mm, protruding widths T1 and T2 of the peripheral protrusions of the first and second rollers are set to 0.25 to 0.5 times the groove widths W1 and W2, and the insertion depths h1 and h2 of the peripheral protrusions to the peripheral grooves are set between 2.0 and 4.0 mm.

Owner:SUMITOMO RUBBER IND LTD

Waste cable cut-off type stripping device

ActiveCN111817215AEffective guidanceAvoid skewBasic electric elementsApparatus for removing/armouring cablesHydraulic cylinderEnvironmental engineering

The invention relates to the technical field of waste cable treatment and further discloses a waste cable cut-off type stripping device. The device comprises a bottom plate and a top plate, wherein asupporting column is fixedly installed between the top of the bottom plate and the bottom of the top plate, a lead cover is fixedly installed between the middles of the two supporting columns on the right side, guide wheels are fixedly mounted on an inner top wall and an inner bottom wall of the lead cover, a cutting base is fixedly installed at the top of the bottom plate, an L-shaped frame is fixed to an upper end of a left side wall of the cutting base, a sleeve is fixedly installed at a top end of the L-shaped frame, a hydraulic cylinder is fixedly installed at the bottom of the top plate,a fixing base is fixedly installed at an output end of the hydraulic cylinder, and a cutter is fixedly installed at the bottom of the fixing base. The waste cable cut-off type stripping device solvesproblems that an existing waste cable stripping device is simple in structure and easy to break during stripping, and the other whole cable is inconvenient to strip and collect.

Owner:ANHUI ZHONGRUN CABLE GRP SHARES CO LTD

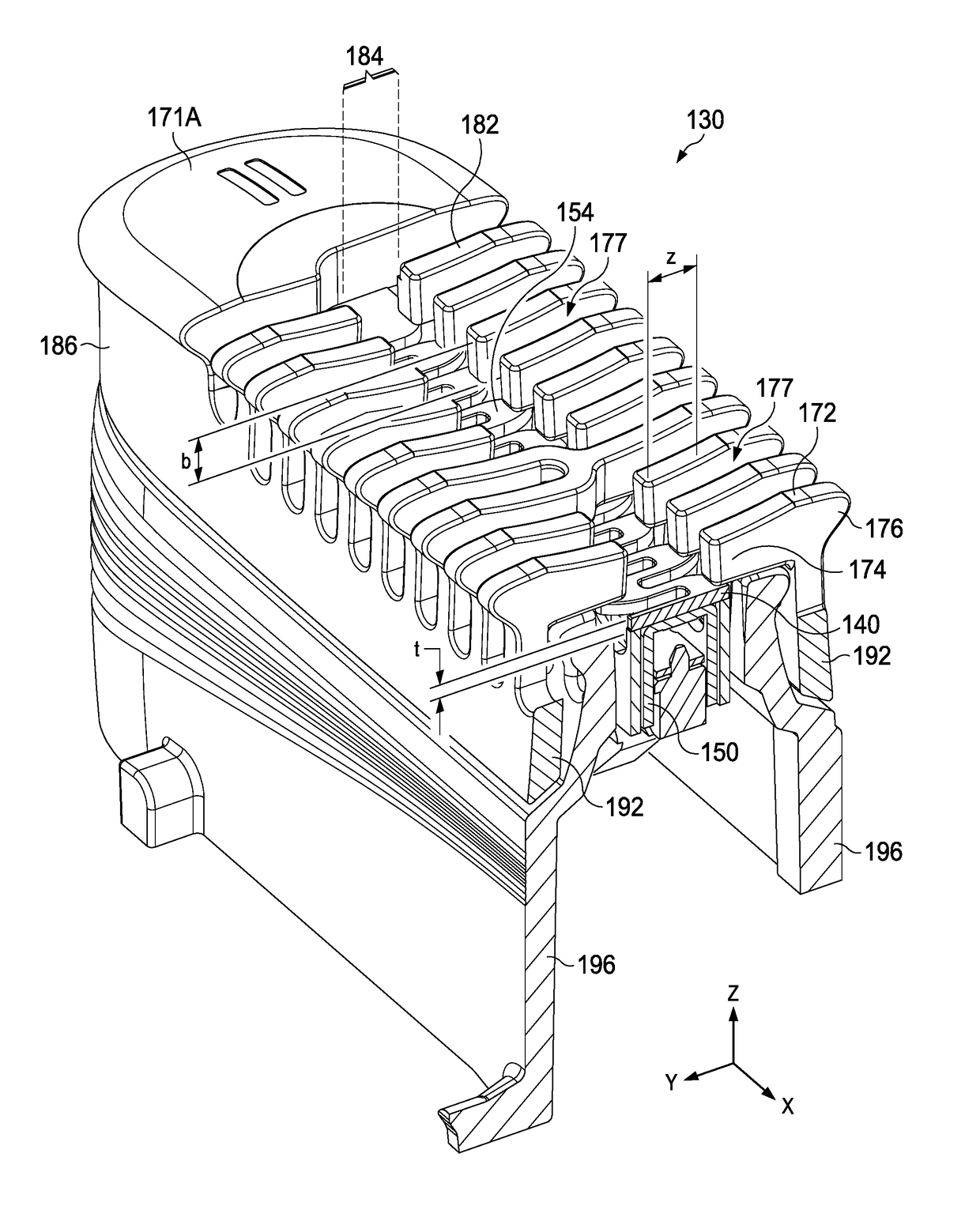

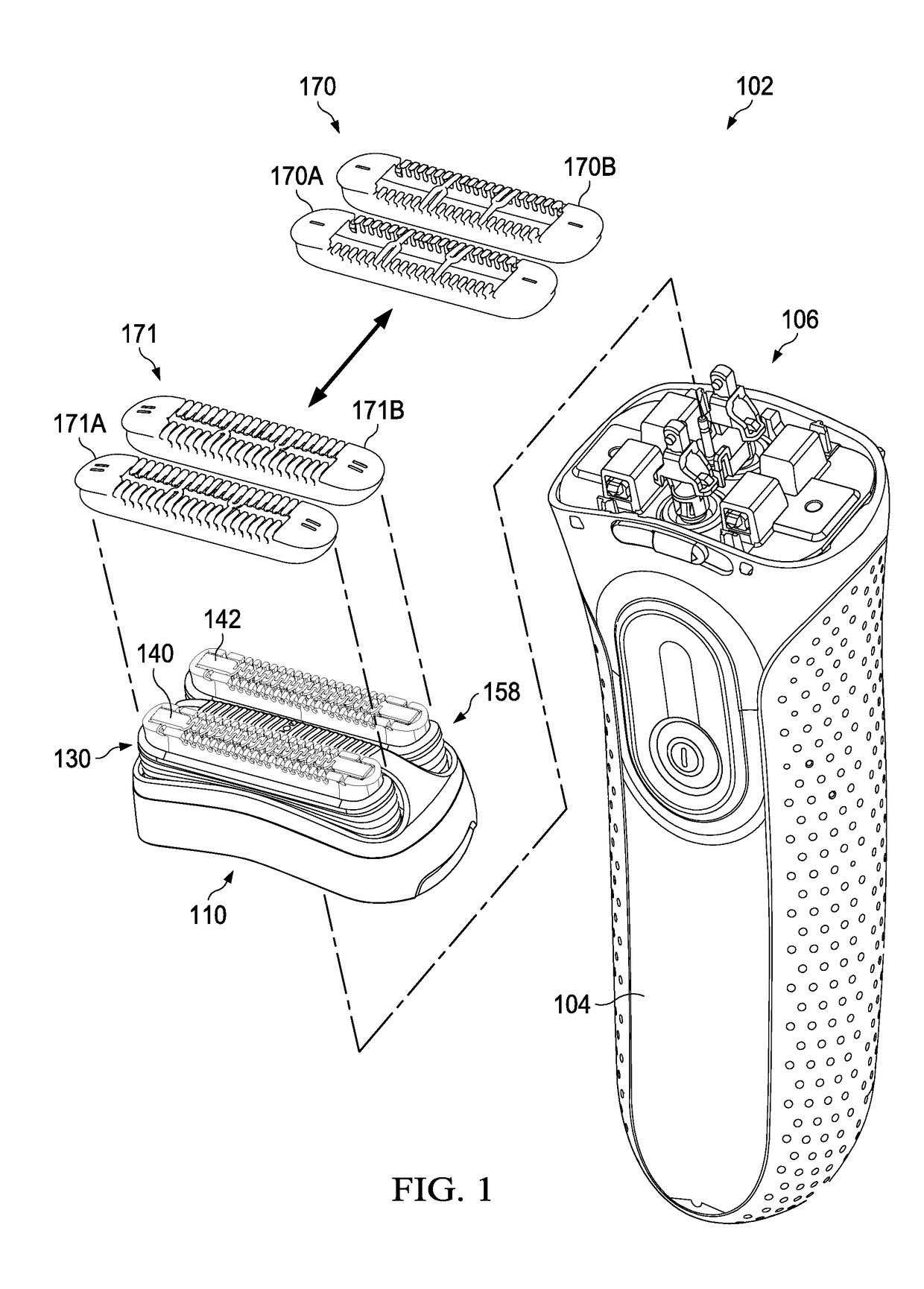

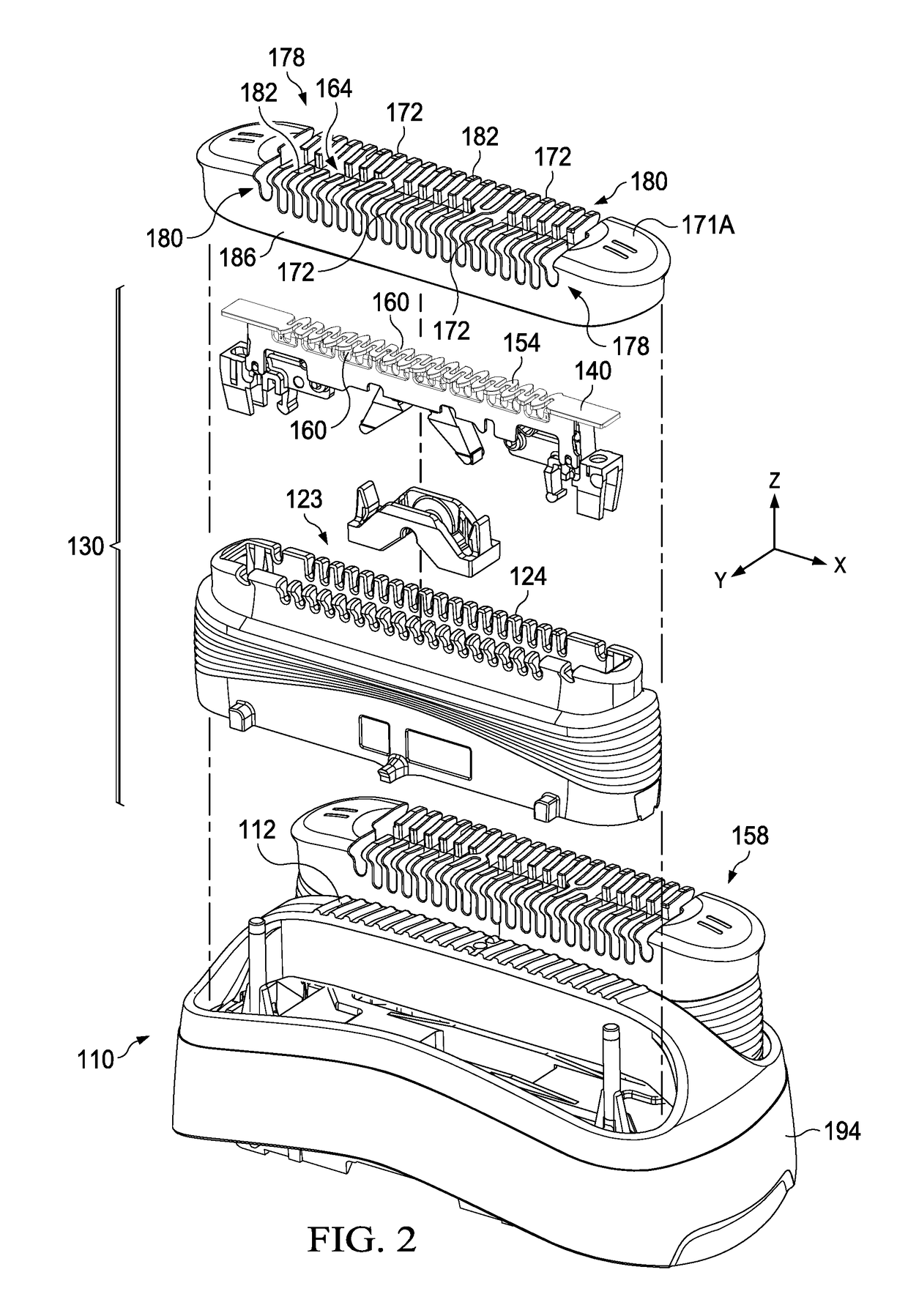

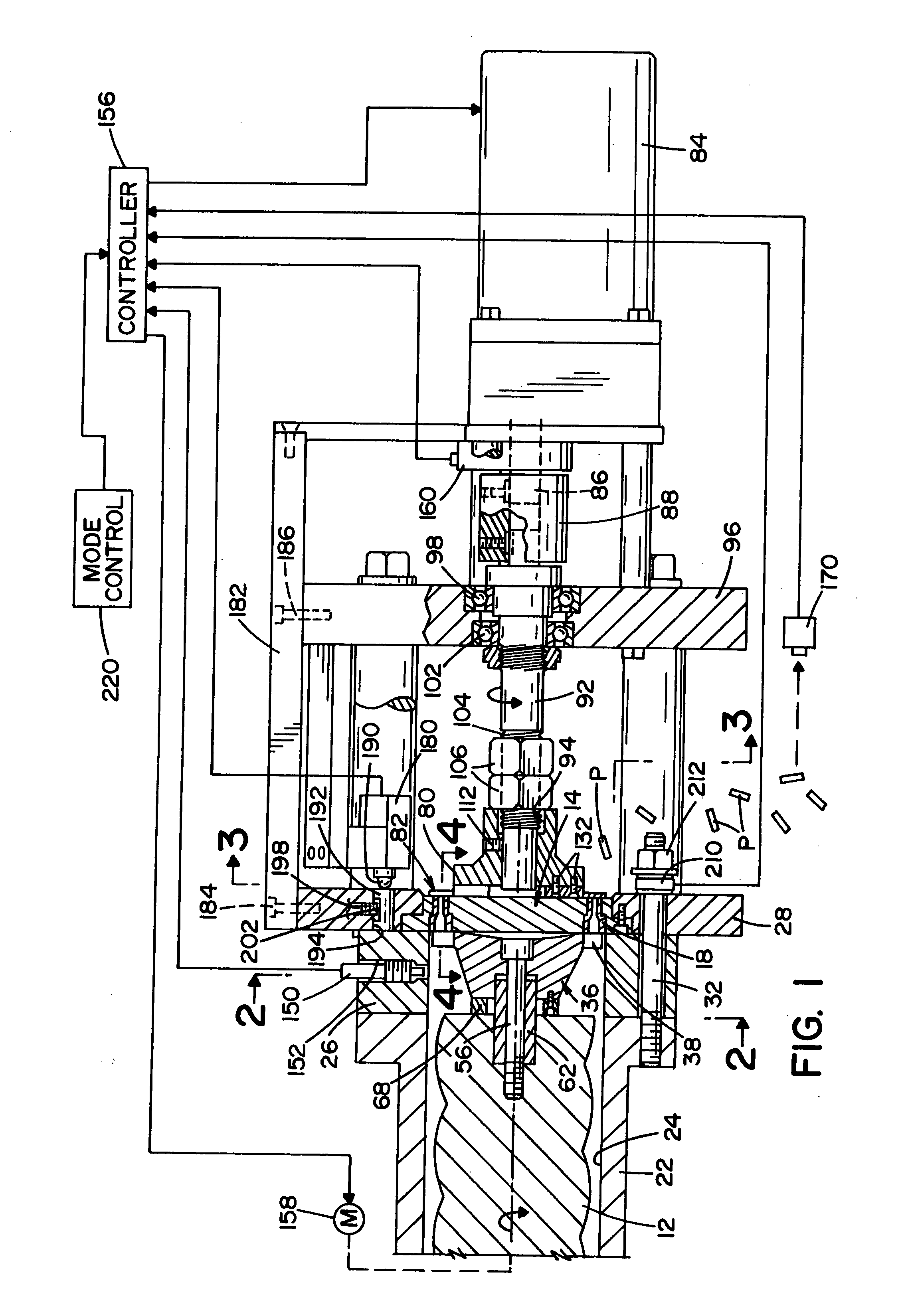

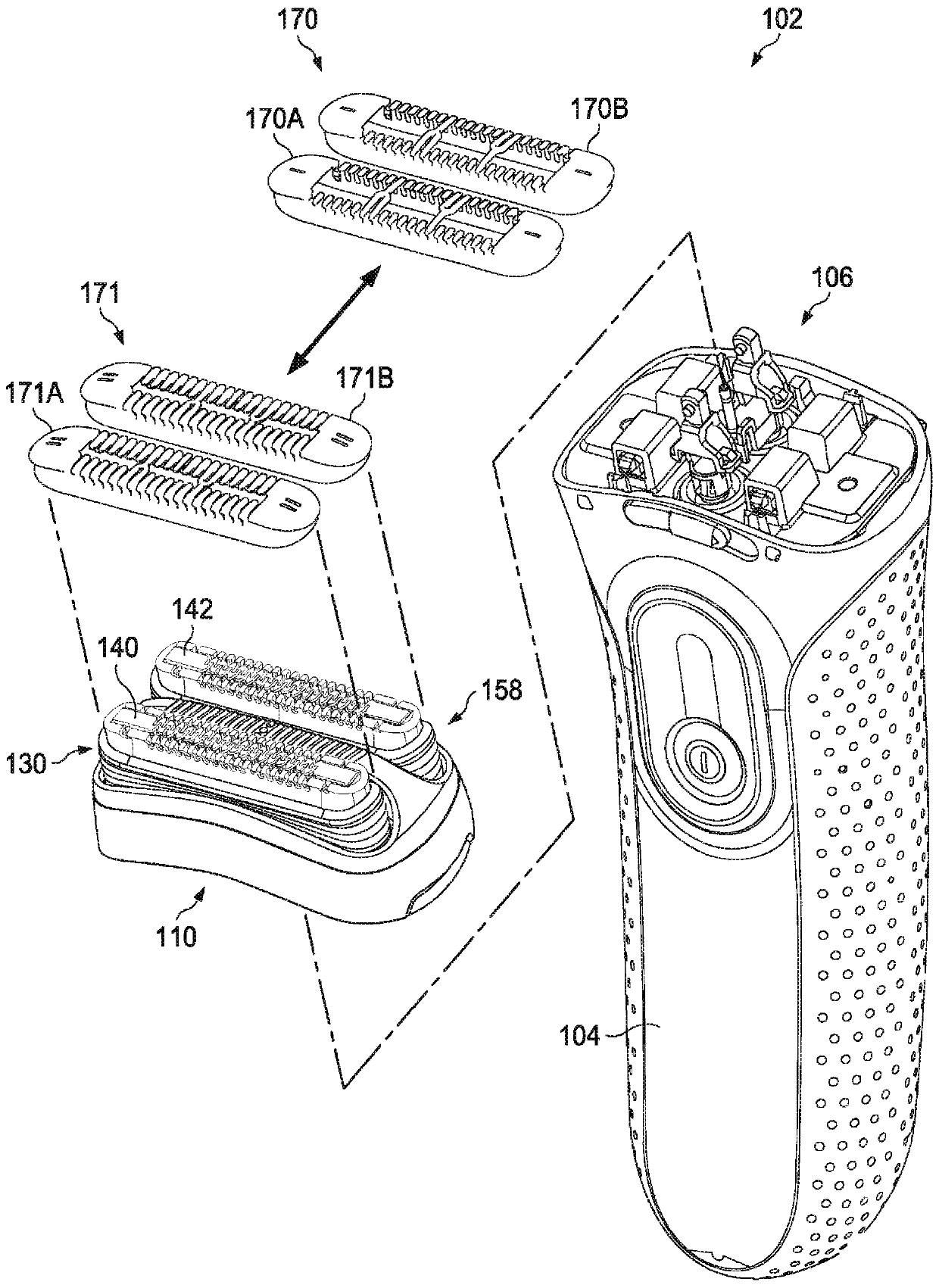

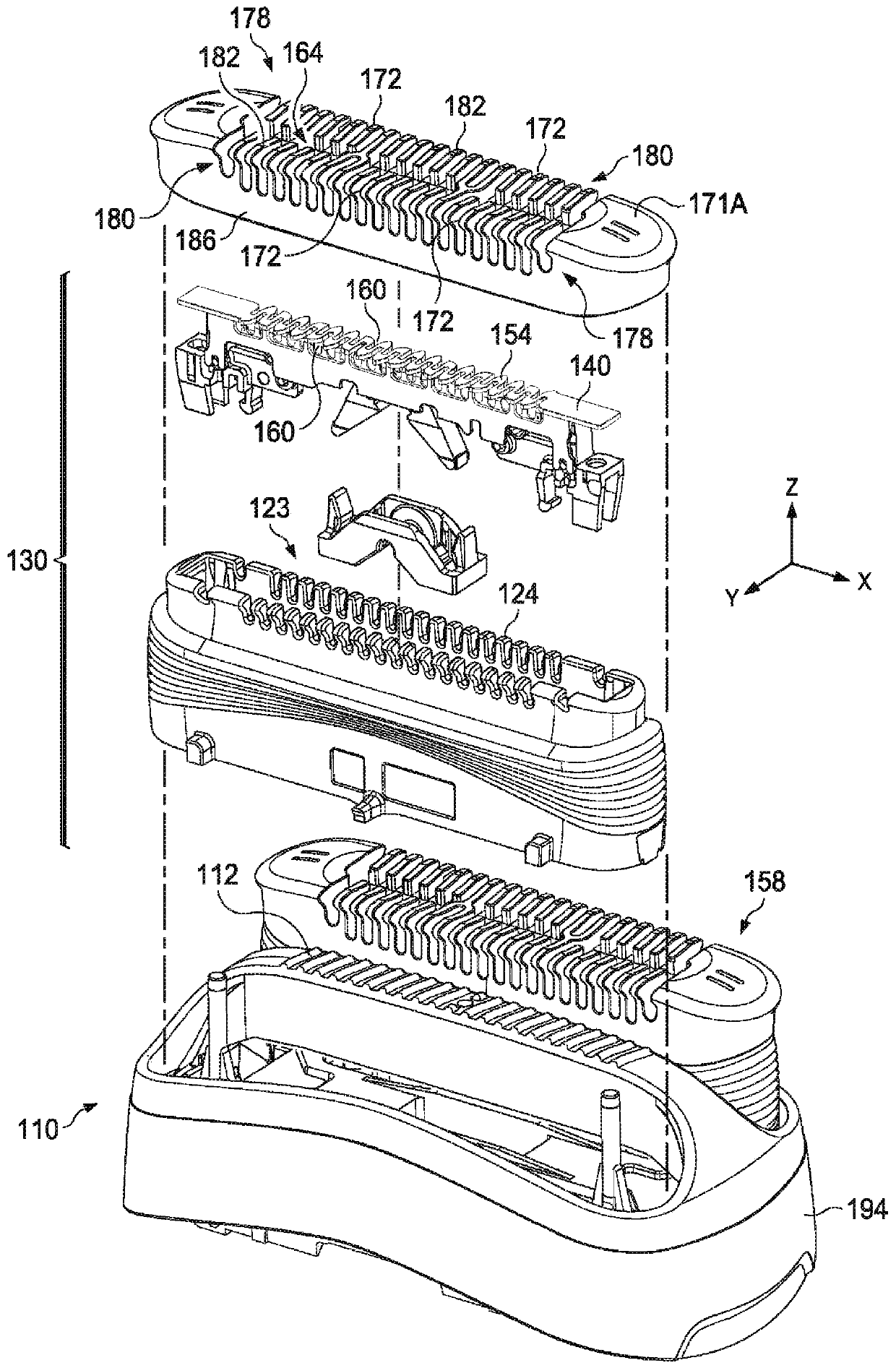

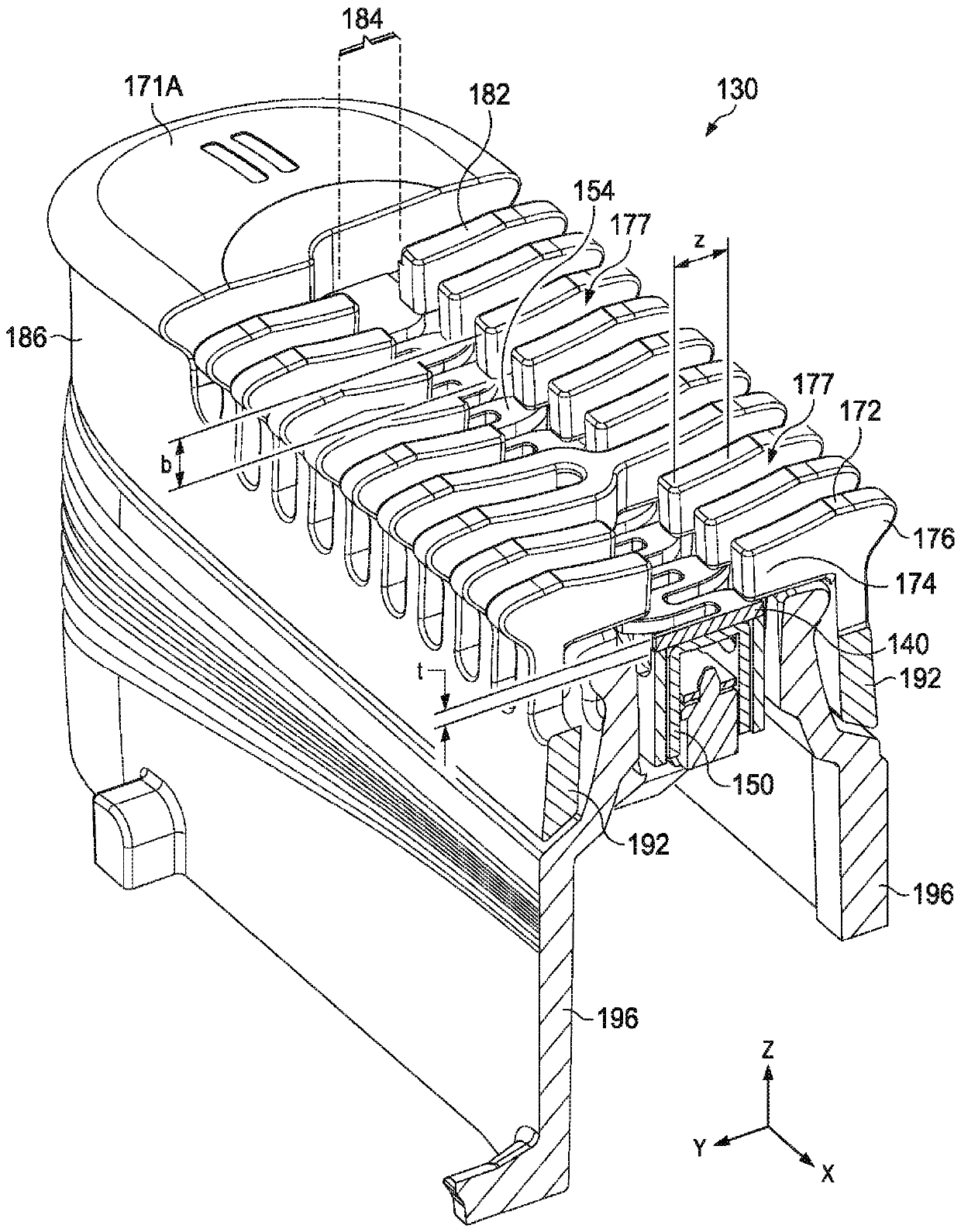

Beard trimmer

ActiveCN109789585AIncrease contact surfaceEasy to handleMetal working apparatusSkin contactMechanical engineering

The invention discloses a beard trimmer which has a handle 104, a motor 106 and a removable head portion 110. The head portion has first long hair cutter unit 130 for trimming the hair length that isprovided with a non-foil type outer cutter 140 and an inner cutter 150. A first comb unit 171A is provided having comb elements 178 located adjacent to multiple cutting slots 160 of the outer cutter.One comb element is provided on each of the opposite sides of the outer cutter. Each comb element provided with a row of comb teeth 172 and comb slots 177 separating the comb teeth from another. Eachof the comb teeth has a tooth skin contact surface 182 which is located on an elevated upper level relative to a cutter skin contact surface 154 of the outer cutter.

Owner:BRAUN GMBH

Double shear material chopper

A material chopper may include a counter shear bar, a plurality of stationary knives associated with the counter shear bar, a shaft, at least one rotor section operatively connected to the shaft, each of the at least one rotor section configured to rotate with the shaft, at least one knife holder in each of the at least one rotor section, at least one knife operatively connected to each of the at least one knife holder, and slots in each of the at least one knife holder, wherein edges of the slot provide counter shear surfaces for the plurality of stationary knives. The material chopper may be added to or incorporated into a harvesting machine such as a combine.

Owner:IOWA STATE UNIV RES FOUND

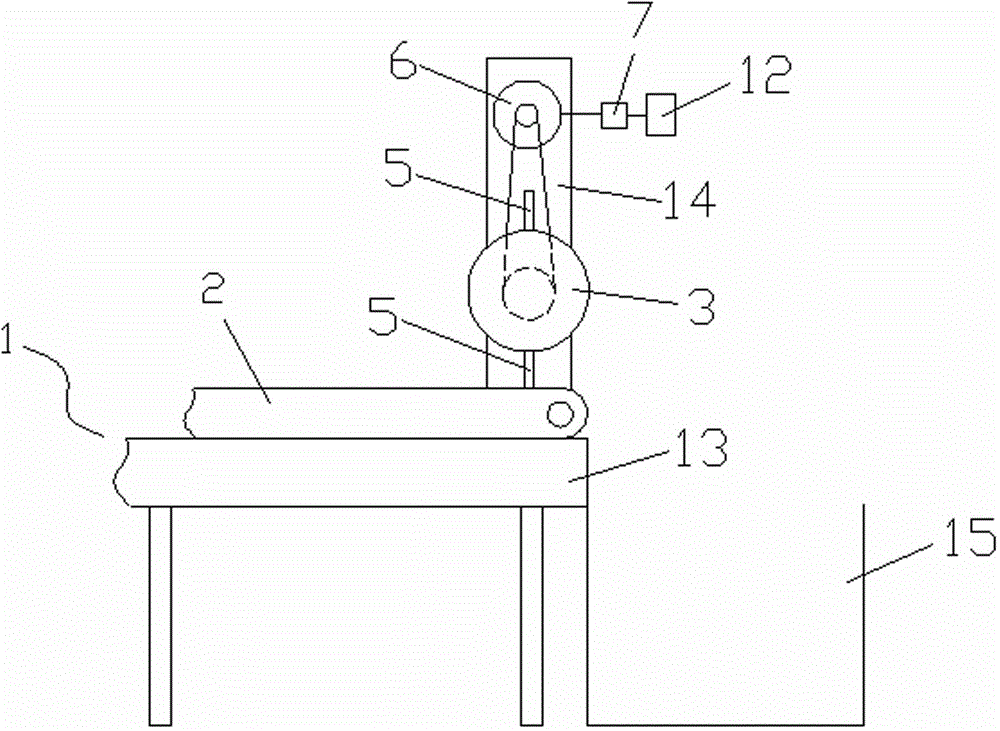

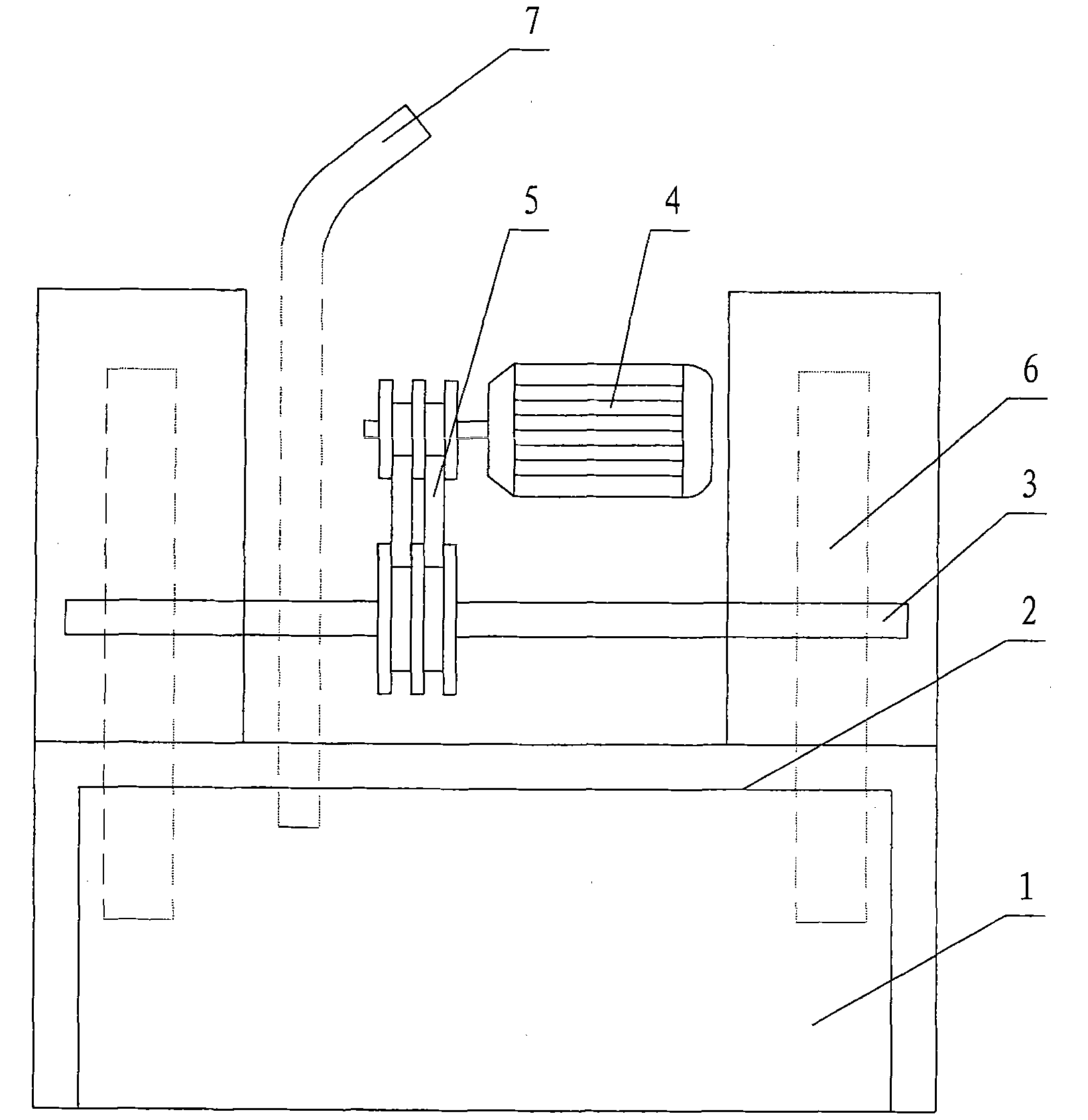

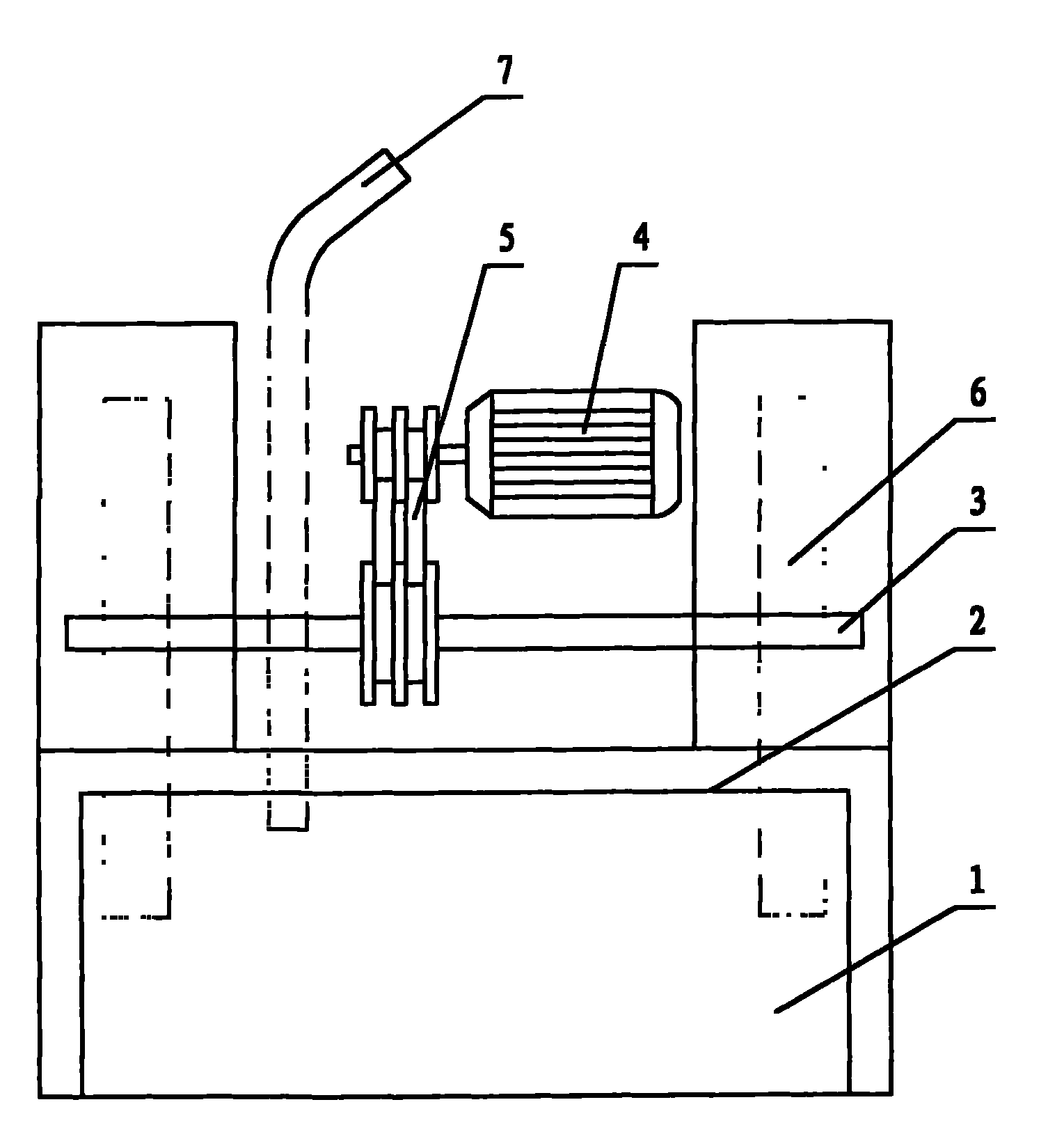

Cloth cutting machine

The invention relates to a cloth cutting machine, which comprises a rack and a delivery mechanism mounted on the rack, wherein the rack is also provided with a cutter head and a limit device; at least two cutters are uniformly fixed on the periphery face of the cutter head; the middle of the cutter head is connected with a motor; the limit device comprises an air cylinder and a limit plate which is connected with an air cylinder arm of the air cylinder; a sensor is arranged at the lower end of the limit plate; the limit plate is vertical to the delivery mechanism; the delivery mechanism, the air cylinder and the sensor are all connected with a controller. The cloth cutting machine has the advantages that the structure is simple, the use is convenient, the operation is stable and reliable, the occurrence of misoperation is avoided, the safety is ensured, the cutting length of cloth is uniform by means of the limit plate, the waste of the cloth is avoided, the working efficiency is improved, and the enterprise cost is reduced.

Owner:WUJIANG XILI MACHINERY FACTORY

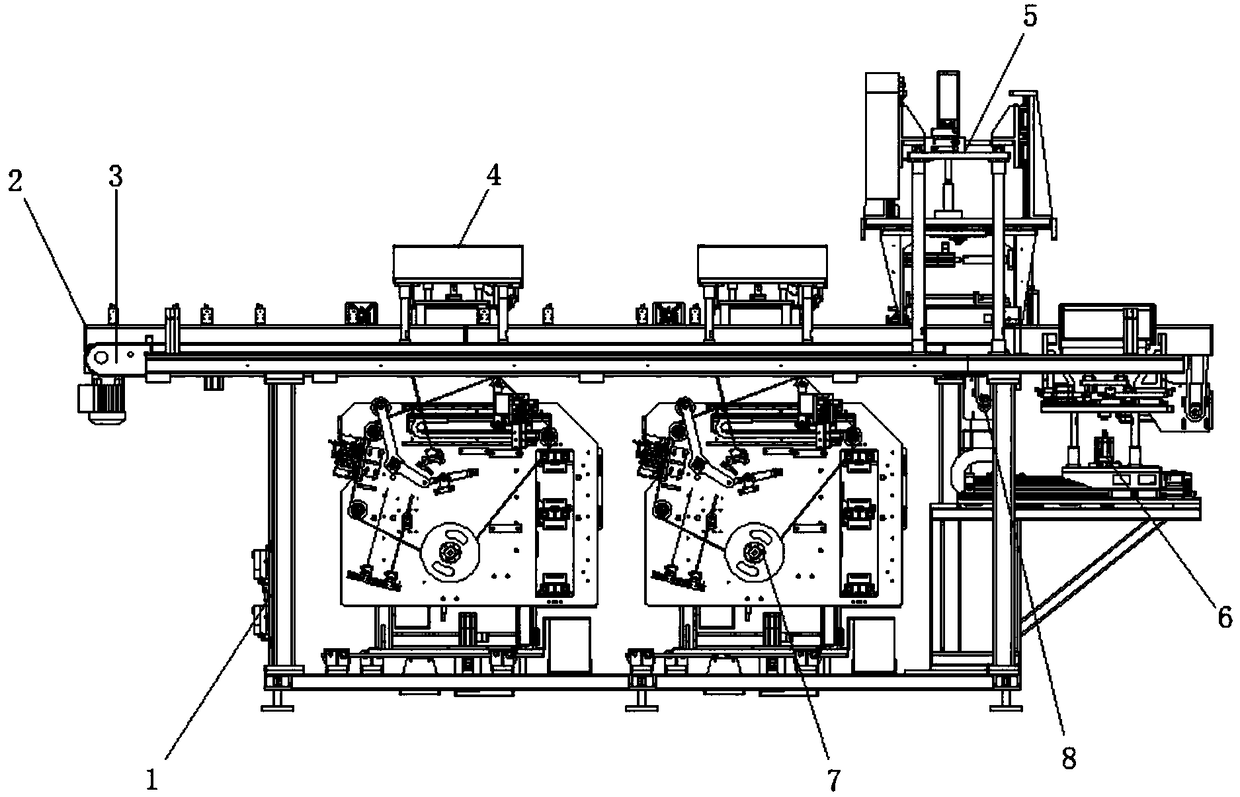

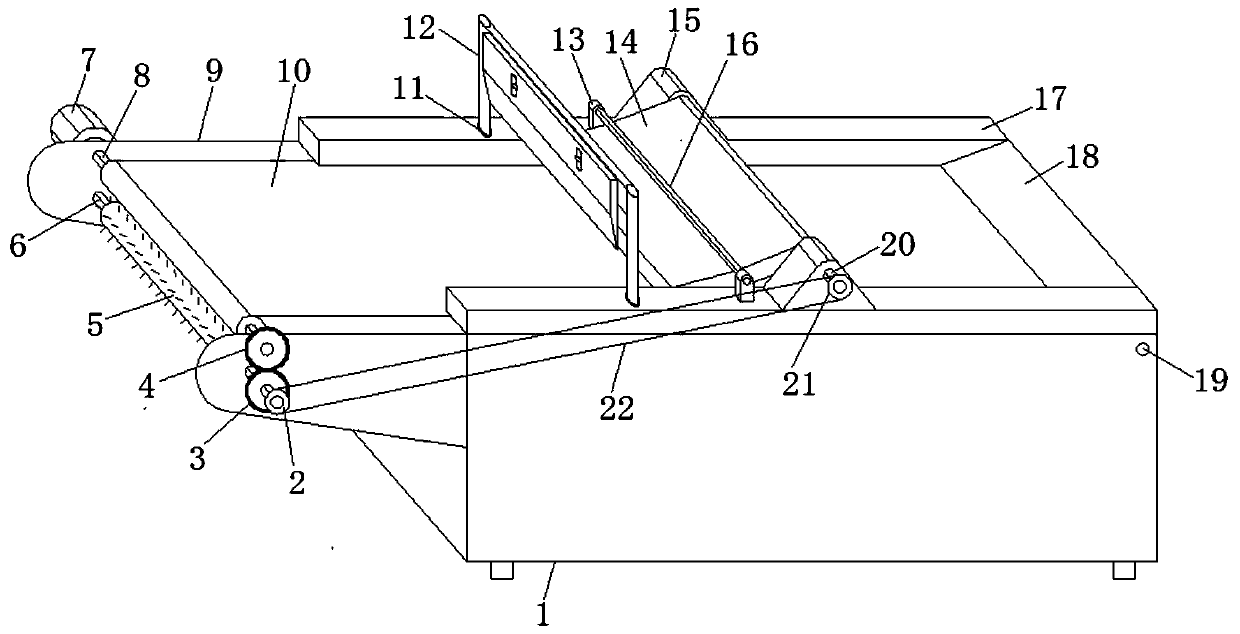

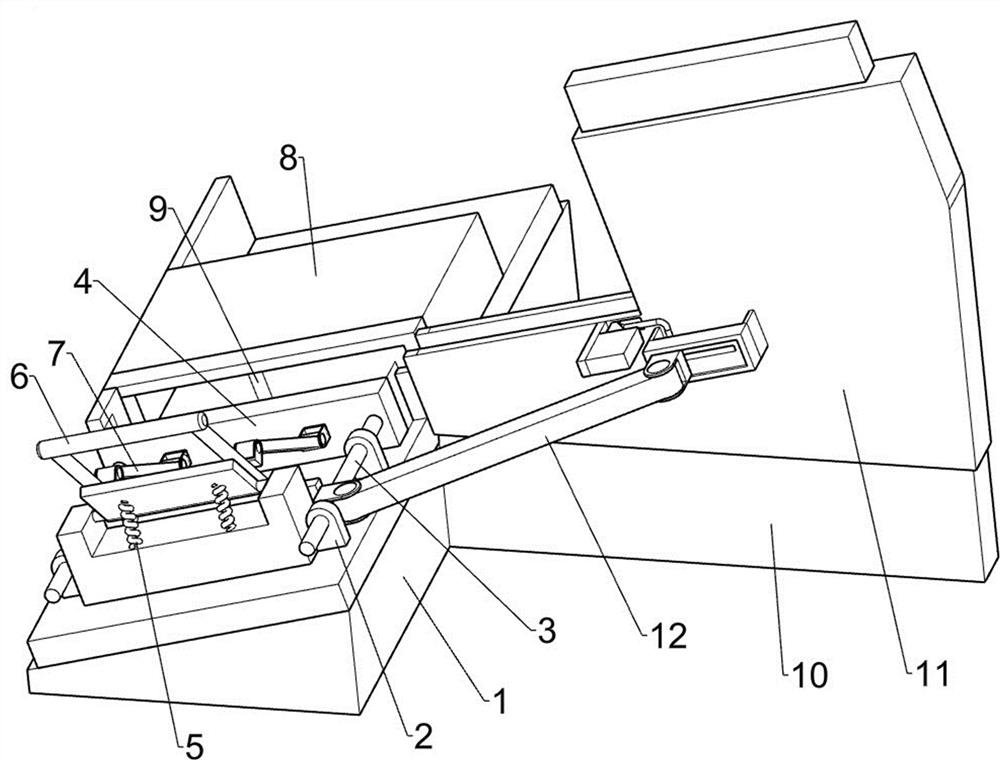

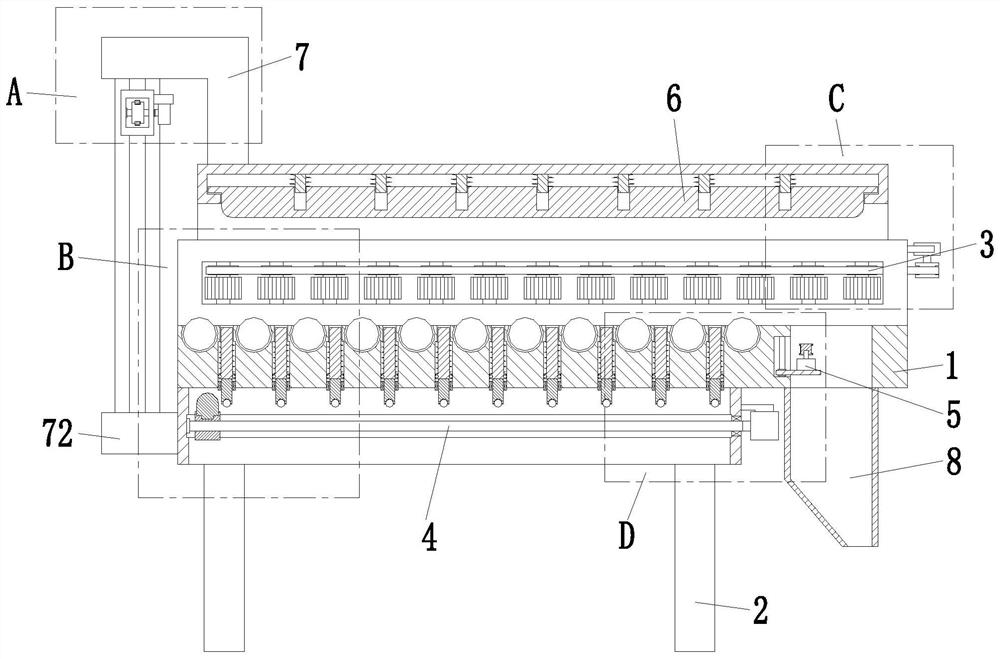

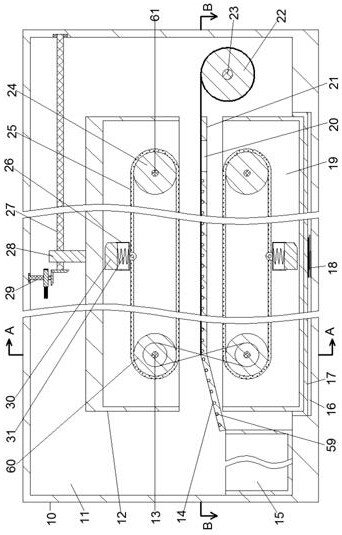

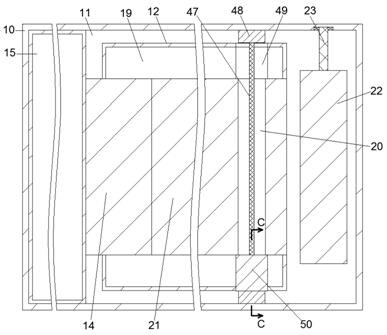

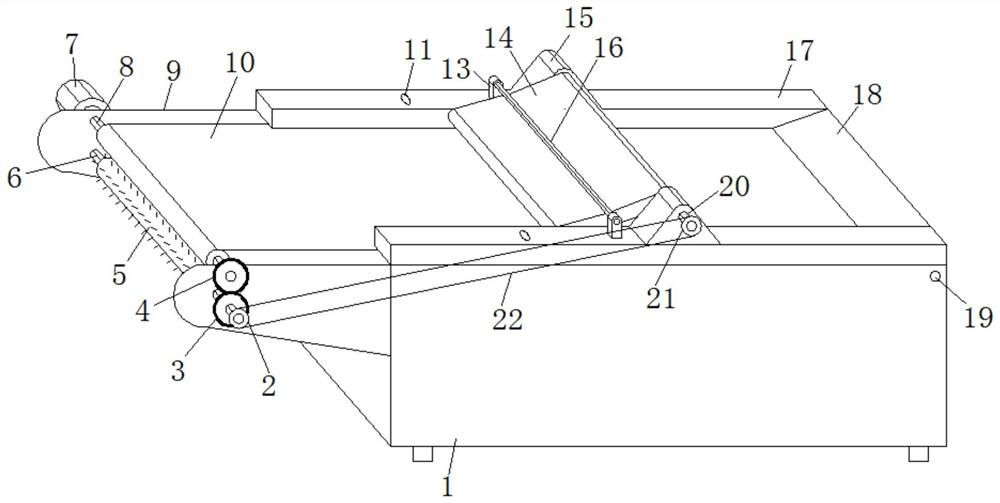

Automatic film pasting device for battery module heat-conducting film

ActiveCN108539244AUniform cutting lengthEasy to grabPrimary cell manufactureAssembling battery machinesFailure rateHeat conducting

The invention discloses an automatic film pasting device for a battery module heat-conducting film. The device comprises a main frame. The main frame is used for bearing each component of a battery module conveying roller way and a battery module NG conveying roller way, a battery module positioning mechanism, a battery module carrying and overturning mechanism, a battery module translation mechanism, and a heat-conducting film pasting mechanism. The heat-conducting film pasting mechanism is positioned below the battery module conveying roller way, and the heat-conducting film pasting mechanism is used for performing film pasting on a battery module conveyed by the battery module conveying roller way. The provided device is high in automation degree, uniform in cutting length of the heat-conducting film, and good in consistency. The device has no apparent bubbles after pasting, and is capable of effectively reducing the manpower, reducing the cost, and improving the productivity. The management is convenient through the reliable stability, and a failure rate is reduced.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

Cloth cutting machine

The invention relates to a cloth cutting machine, which comprises a rack and a delivery mechanism mounted on the rack, wherein the rack is also provided with a cutter head and a limit device; at least two cutters are uniformly fixed on the periphery face of the cutter head; the middle of the cutter head is connected with a motor; the limit device comprises an air cylinder and a limit plate which is connected with an air cylinder arm of the air cylinder; a sensor is arranged at the lower end of the limit plate; the limit plate is vertical to the delivery mechanism; the delivery mechanism, the air cylinder and the sensor are all connected with a controller. The cloth cutting machine has the advantages that the structure is simple, the use is convenient, the operation is stable and reliable, the occurrence of misoperation is avoided, the safety is ensured, the cutting length of cloth is uniform by means of the limit plate, the waste of the cloth is avoided, the working efficiency is improved, and the enterprise cost is reduced.

Owner:WUJIANG XILI MACHINERY FACTORY

Dried beancurd sticks capable of being quickly soaked and making method thereof

The invention discloses a making method of dried beancurd sticks capable of being quickly soaked. The method comprises the following steps of 1, milk making, wherein soybean milk is placed in a pot for milk boiling, and after the soybean milk is boiled, milk boiling continues for 20 minutes; 2, peeling, wherein skin peeling is conducted for the first time when the soybean milk is boiled for 20 minutes, and then skin peeling is carried out once every 10-15 minutes; 3, baking, wherein soybean milk skins peeled in the second step are baked in the environment of 100 DEG C, after drying, high-temperature steam is used for softening dried beancurd rolls, and the dried beancurd rolls are cut into short strips to obtain the dried beancurd sticks capable of being quickly soaked. The dried beancurdsticks can be softened after being soaked for 10 minutes through cover sealing, a person can eat the dried beancurd sticks whenever he / she wants, early soaking is not needed, and the dried beancurd sticks are convenient to eat.

Owner:江西高安市惠而美食品有限公司

Extrusion molding processing machine and method for manufacturing sealing rubber strip

InactiveCN113071085ARapid coolingUniform cutting lengthMetal working apparatusComposite materialWater pipe

The invention belongs to the technical field of rubber strips, and particularly relates to an extrusion molding processing machine and method for manufacturing a sealing rubber strip. When the sealing rubber strip is subjected to fixed-length cutting in the extrusion process of the sealing rubber strip, the length of the rubber strip cut by a cutting blade every time is equal to the arc length between a clamping mechanism and the cutting blade along the circumferential surface of the disc, and due to the fact that the arc length between the clamping mechanism and the cutting blade along the circumferential surface of the disc is constant, the length of the rubber strip cut every time is uniform. When the sealing rubber strip is cooled in the extrusion process of the sealing rubber strip, cooling water in a cooling water pipe, an annular water pipe and a cooling water tank can be exchanged, so that the cooling effect of the cooling water in the cooling water tank is ensured, and rapid cooling of the sealing rubber strip is realized.

Owner:刘斌

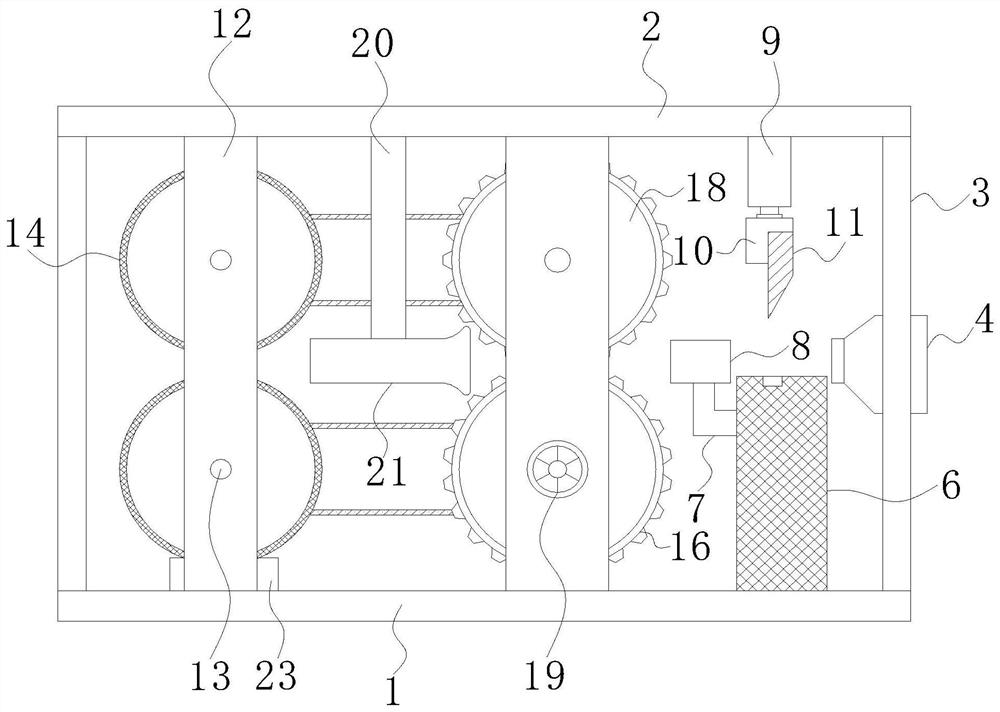

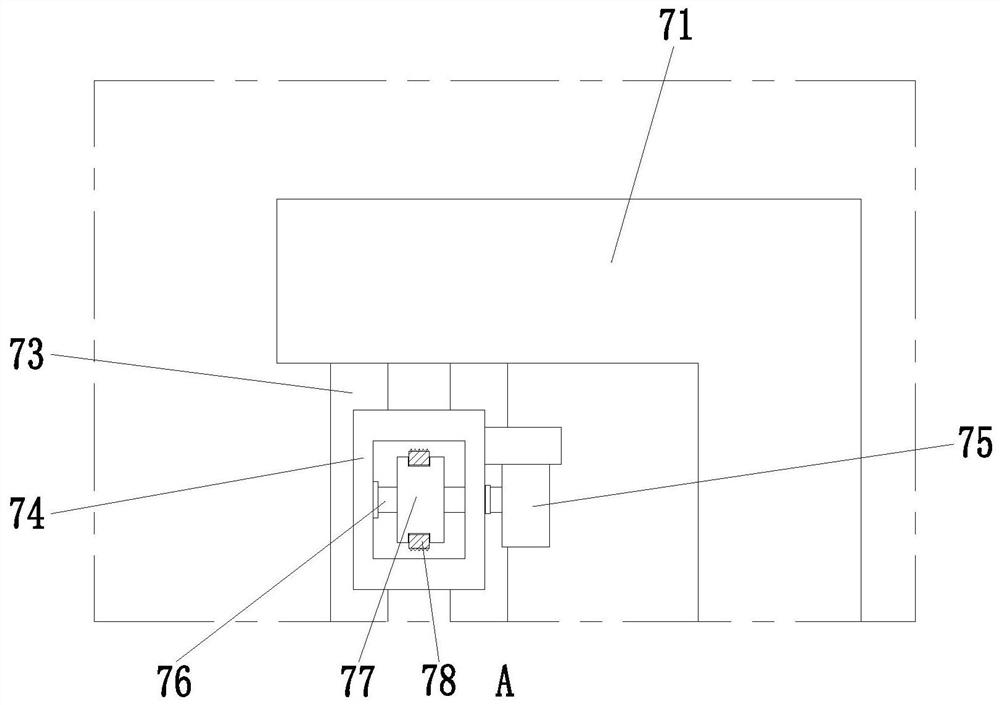

Cutting equipment for hardware pipe fitting

ActiveCN107813006AUniform cutting lengthAvoid spendingTube shearing machinesShearing machine accessoriesTransfer mechanismAirbag

The invention relates to the field of pipe fitting cutting, in particular to cutting equipment for a hardware pipe fitting. The cutting equipment comprises a supporting table, a collection box, a first gear, a clamping mechanism, a transferring mechanism, a cutting mechanism and an abutting mechanism; the first gear is an incomplete gear; the clamping mechanism comprises a first clamping unit anda second clamping unit; the first clamping unit comprises a first clamping block and a protruding block fixedly connected with the first clamping block; the second clamping unit comprises a second clamping block and an airbag; the transferring mechanism comprises an adjusting rod, a supporting strip and a rotating rod; the cutting mechanism comprises a second rack, a second gear, a third rack anda cutter; and the abutting mechanism comprises an air cylinder, an abutting strip and abutting blocks. When the technical scheme is adopted, the problem that the hardware pipe fitting is likely to deform in the fixing process is avoided effectively, meanwhile, it can be guaranteed that the cutting lengths of the hardware pipe fitting are uniform, and the problem that the end, making contact with the ground firstly, of the hardware pipe fitting is prone to being damaged is solved effectively.

Owner:华汉致信(宁波)供应链管理有限公司

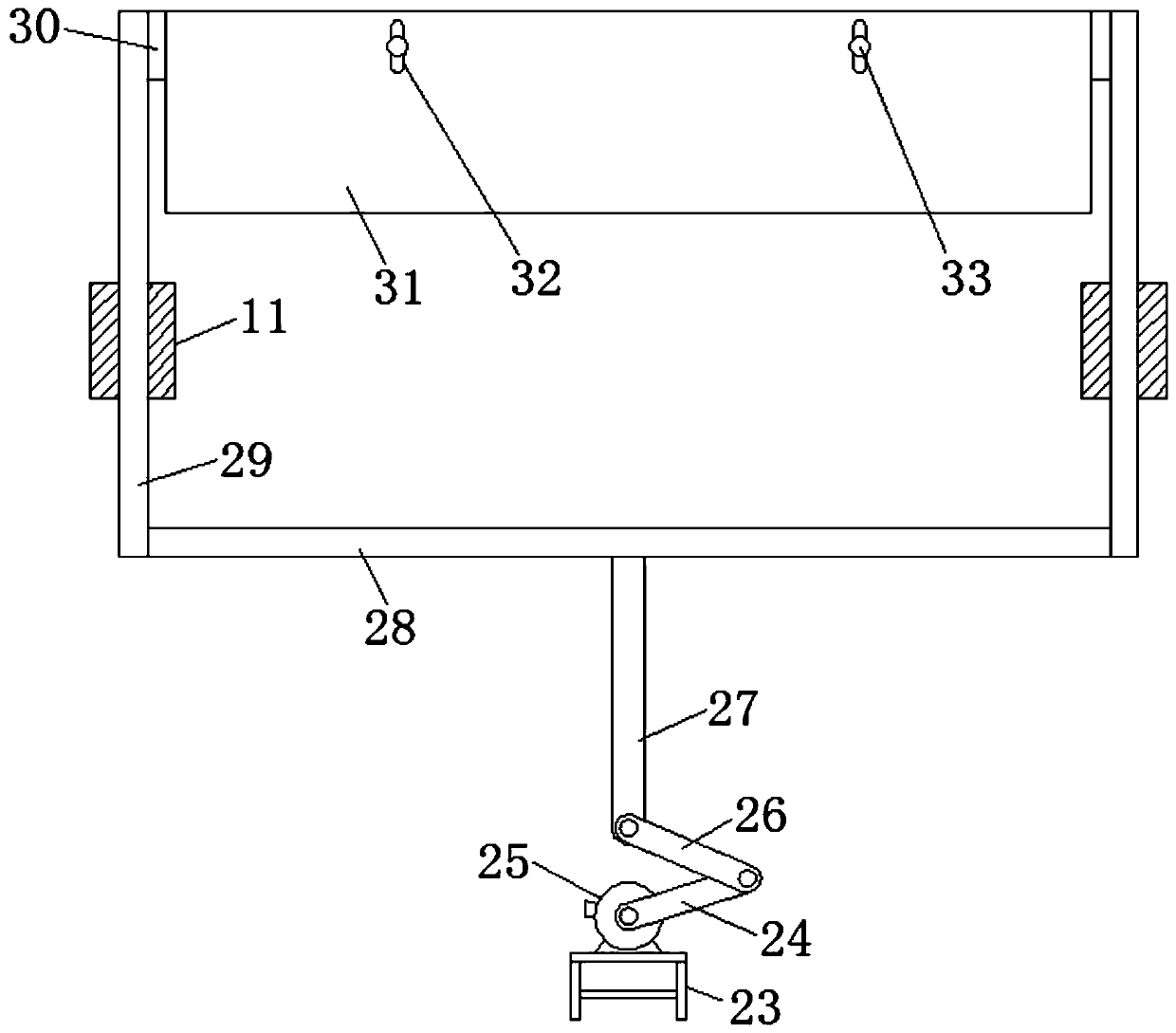

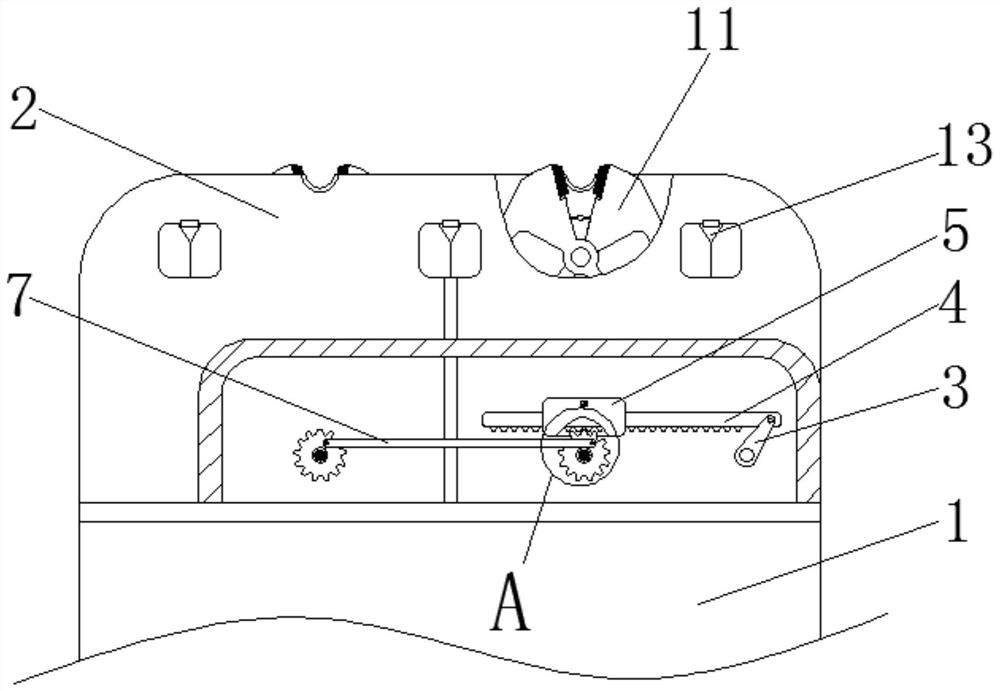

Equal-length cutting device for building small brick strips

InactiveCN111645177AUniform cutting lengthImprove the quality of workAuxillary shaping apparatusBrickArchitectural engineering

The invention relates to a cutting device, and particularly relates to an equal-length cutting device for building small brick strips. The equal-length cutting device for the building small brick strips can replace manual work to cut the small brick strips into the required length, the cutting length of the small brick strips is uniform, and the working quality is high. The equal-length cutting device for the building small brick strips comprises a mounting base, a pushing assembly and a cutting assembly, wherein the pushing assembly is mounted on the mounting base and is pushed in a rotatingmode, and the cutting assembly is mounted on the mounting base and conducts cutting in a pushing mode. According to the equal-length cutting device for the building small brick strips, the small brickstrips needing to be cut can be pushed into the device to be cut through the pushing assembly, the small brick strips can be cut through the cutting assembly, thus the cutting length of the small brick strips is more uniform, and the working quality of people is improved; and the small brick strips needing to be cut can be placed through a placing frame, thus the small brick strips needing to becut do not need to be placed into the device manually any more, and manpower is saved.

Owner:马桂莲

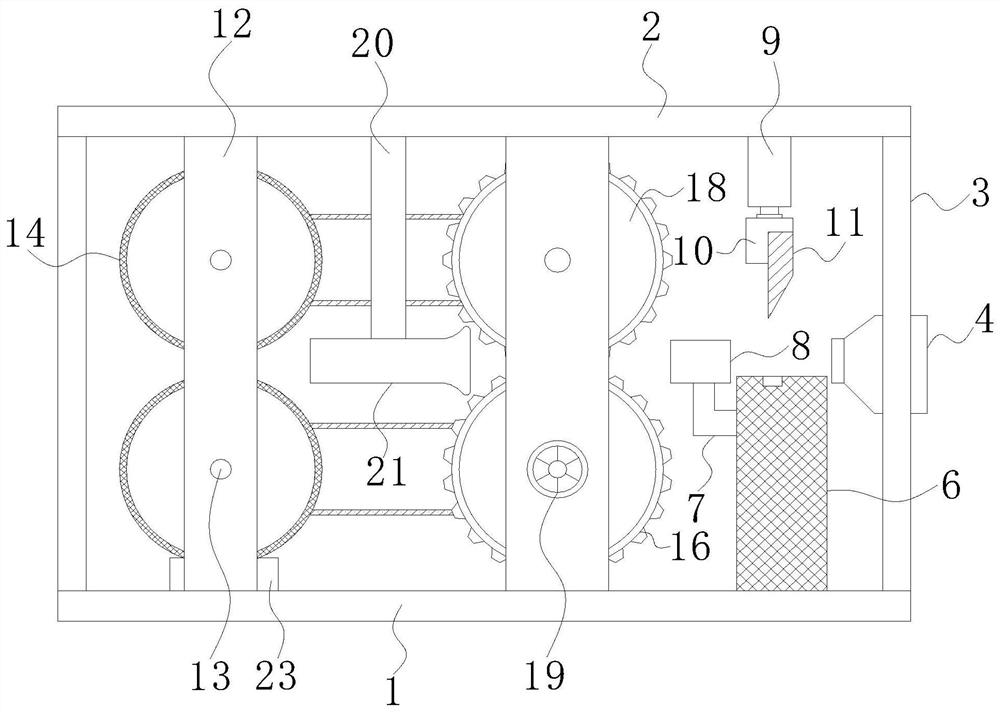

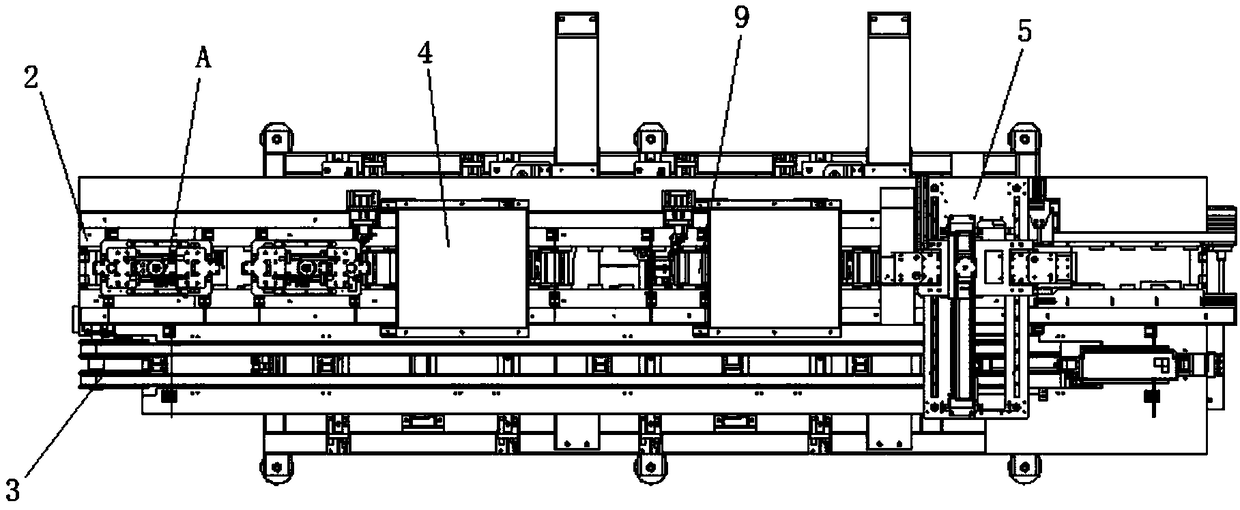

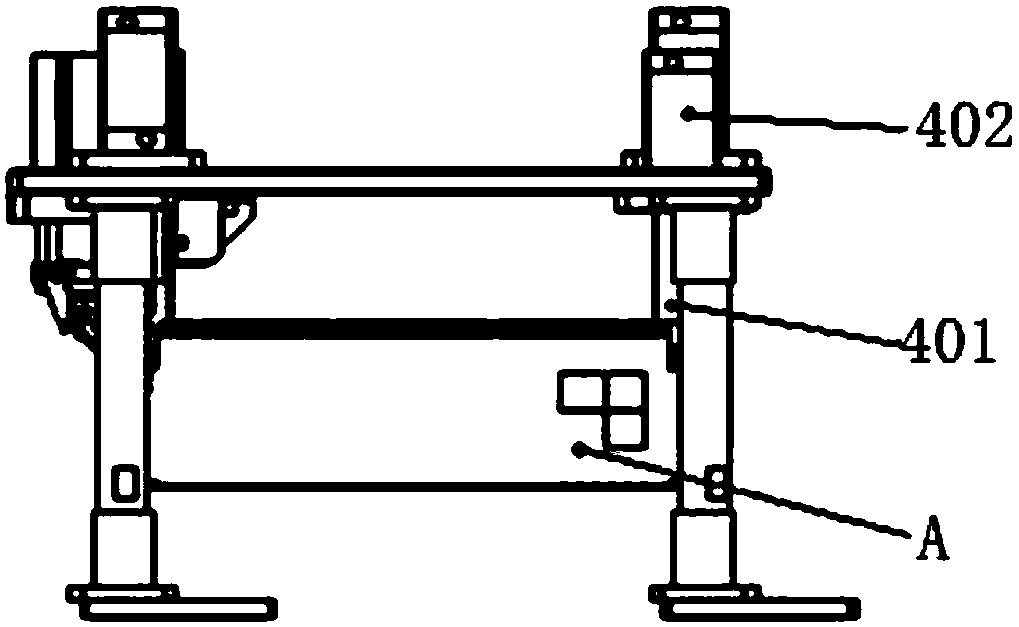

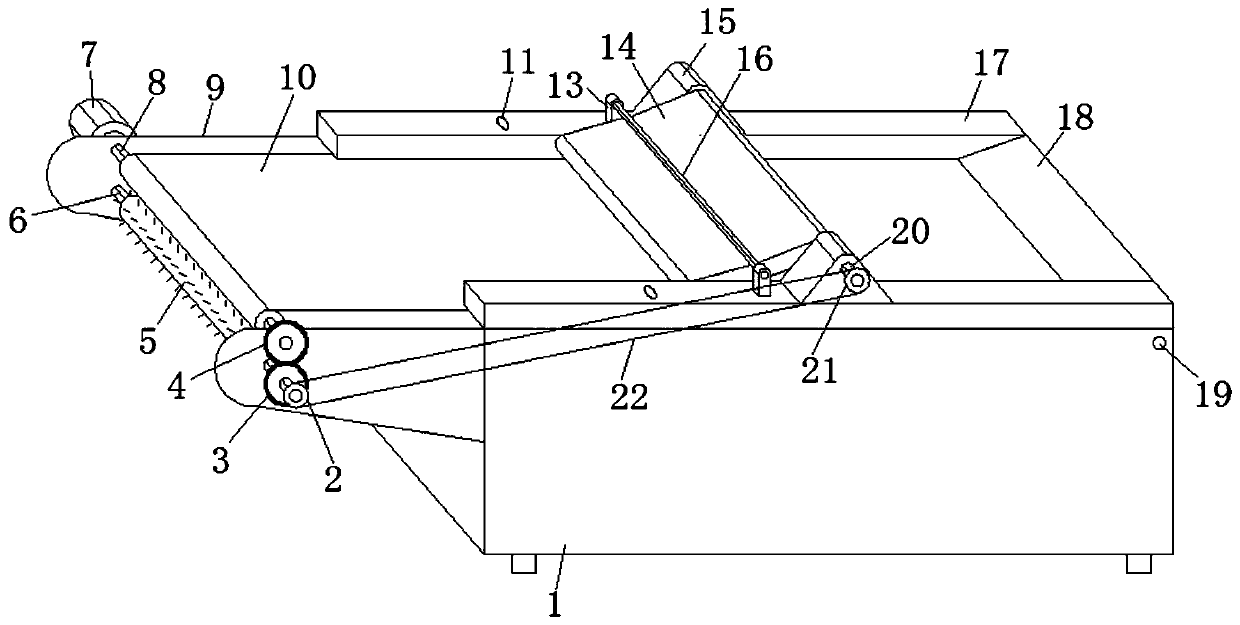

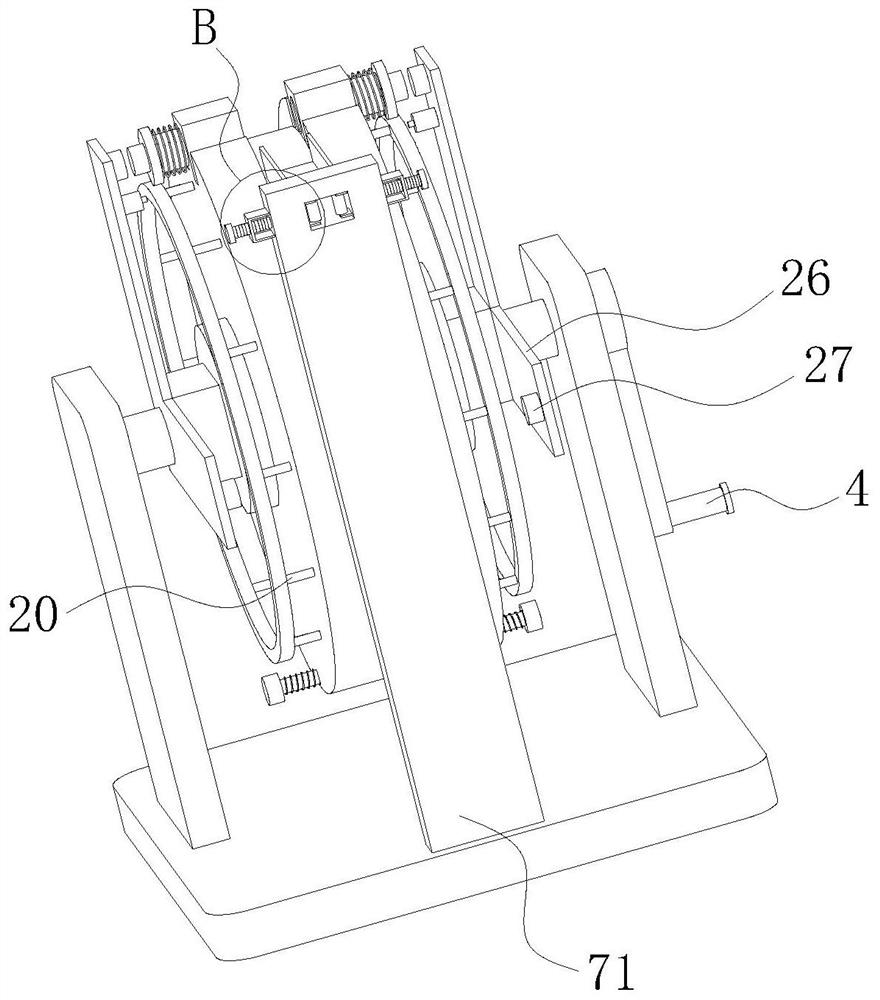

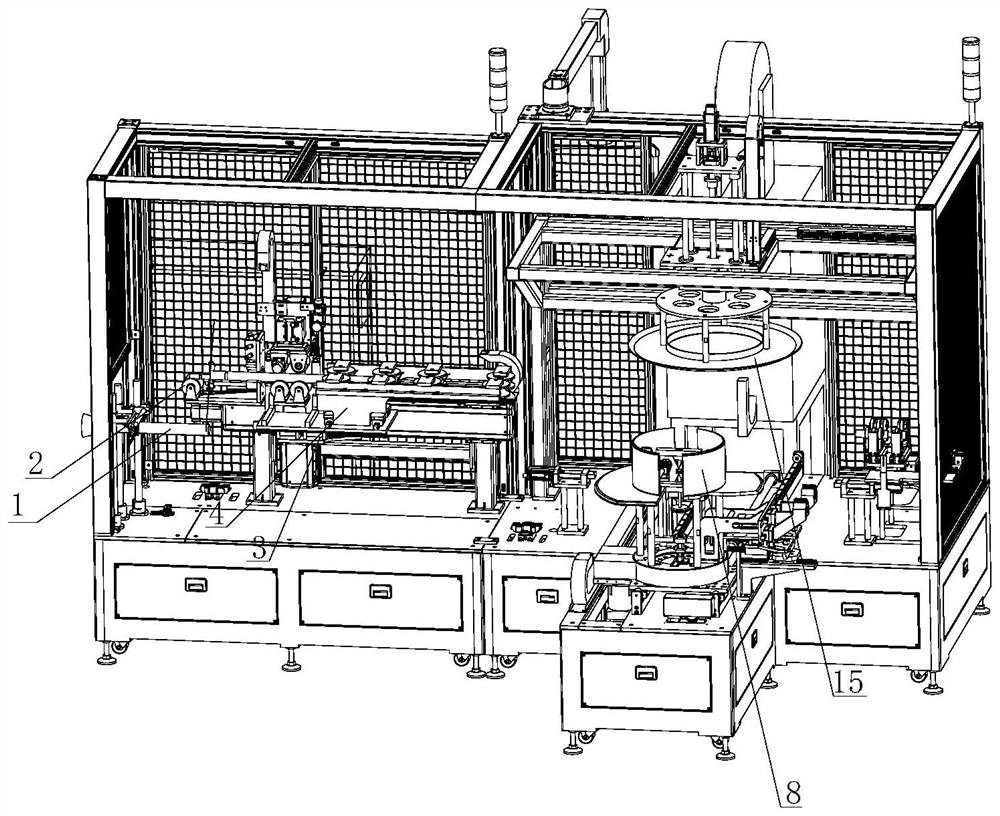

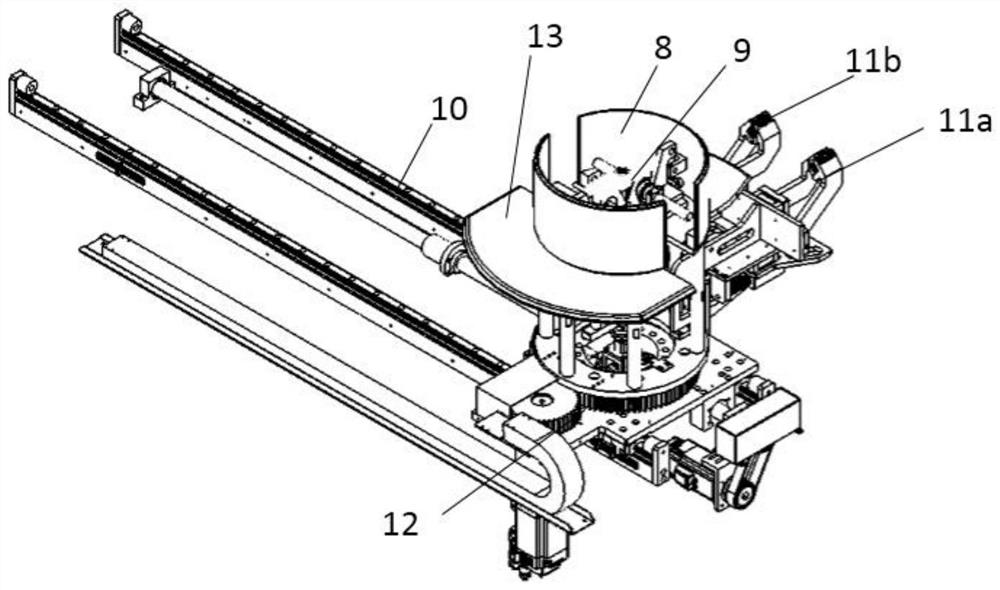

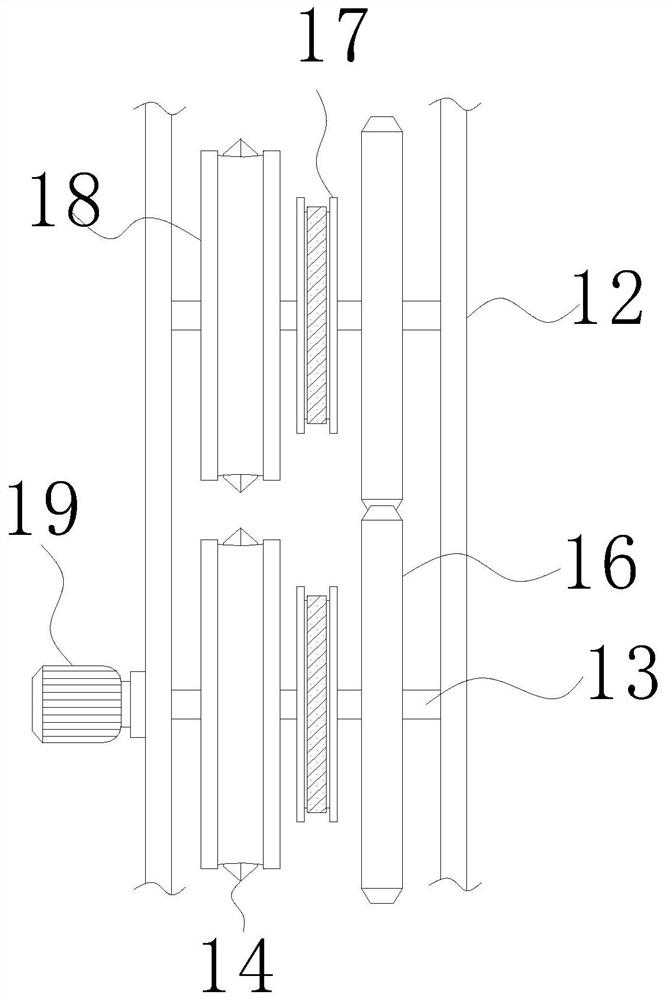

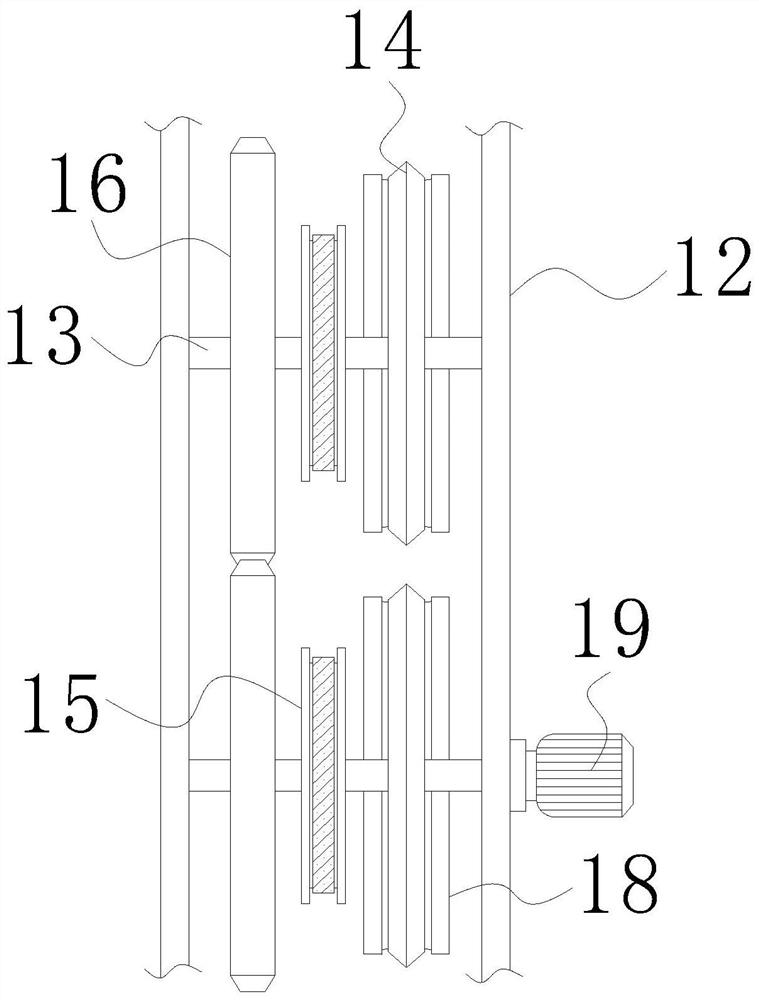

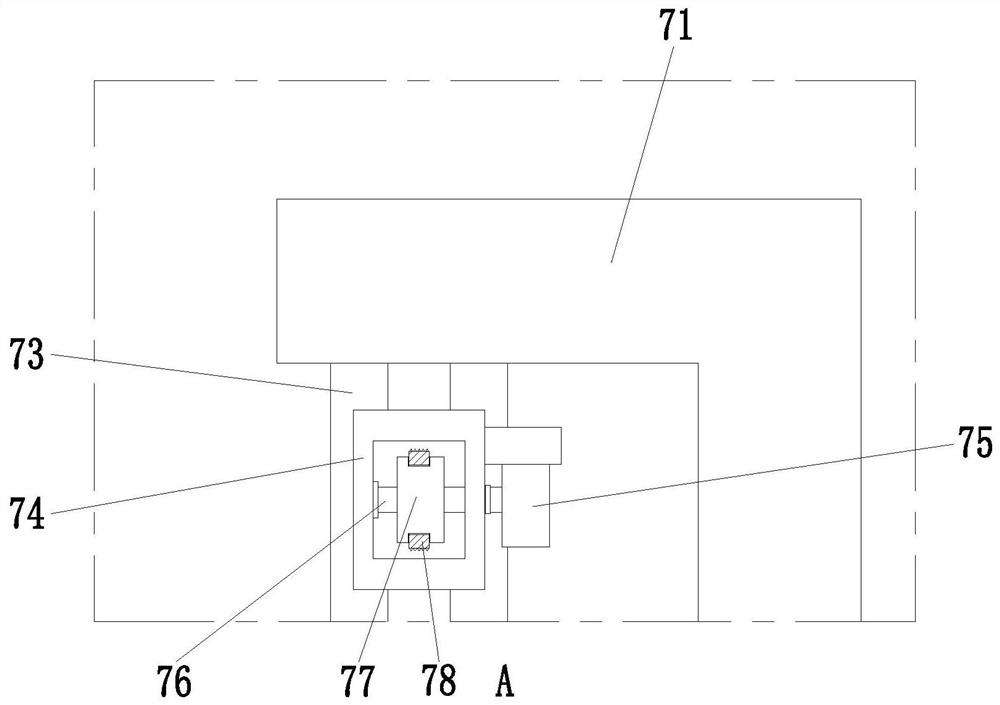

Large-core-diameter wire harness user-defined cutting and rolling equipment

PendingCN114194936AUniform cutting lengthImprove work efficiencyFilament handlingBrakeControl engineering

The invention relates to the technical field of cable processing, in particular to large-core-diameter wire harness user-defined cutting and rolling equipment which is compatible with cables with various wire diameters, so that the cutting length of the cables is uniform and can be customized, the working efficiency of cable cutting is improved, and the practicability is improved; comprising a machine table, a robot, a wire feeding mechanism and a wire winding and packaging and upper rotating mechanism, and the wire feeding mechanism and the wire winding and packaging and upper rotating mechanism are all installed on the machine table; the wire feeding mechanism comprises a rack, a wire inlet guide mechanism, a roller, a first sliding table module, a second sliding table module, a band-type brake, a rubber coating roller, a guide roller and a sensor, the rack is installed on the machine table, the wire inlet guide mechanism is installed on the rack, the first sliding table module is installed on the rack, the second sliding table module is installed on the first sliding table module, the roller is installed on the rack, and the guide roller is installed on the rack. The band-type brake is installed on the second sliding table module, the sensor is fixed through the band-type brake, and the rubber coating roller is installed on the first sliding table module and rotates relative to the first sliding table module.

Owner:利捷得(苏州)自动化有限公司

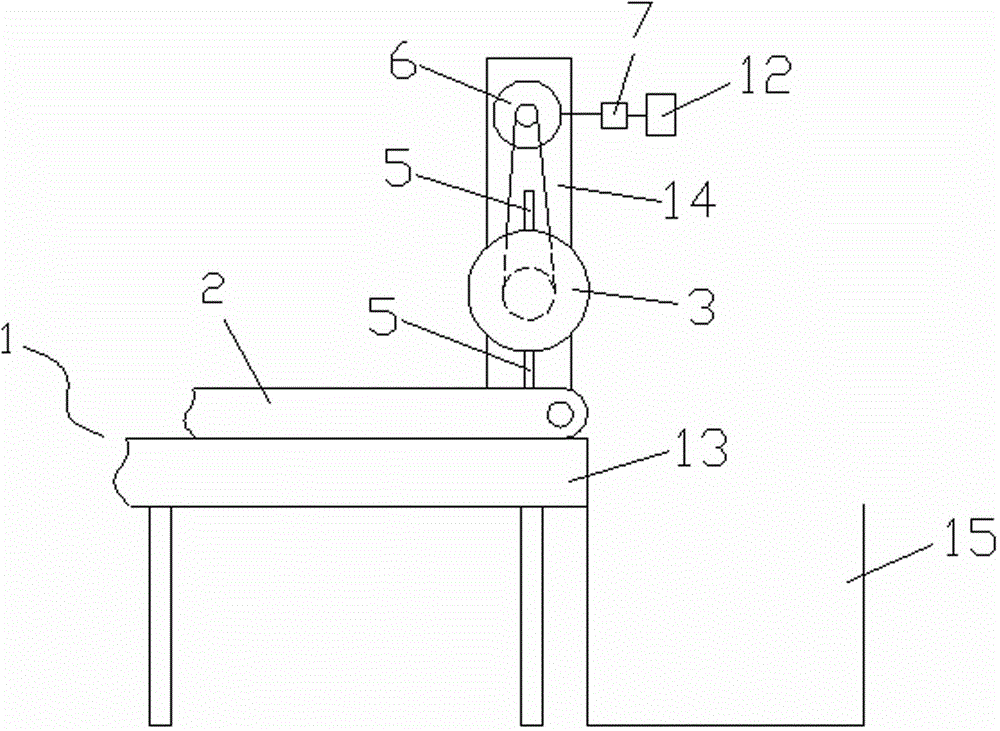

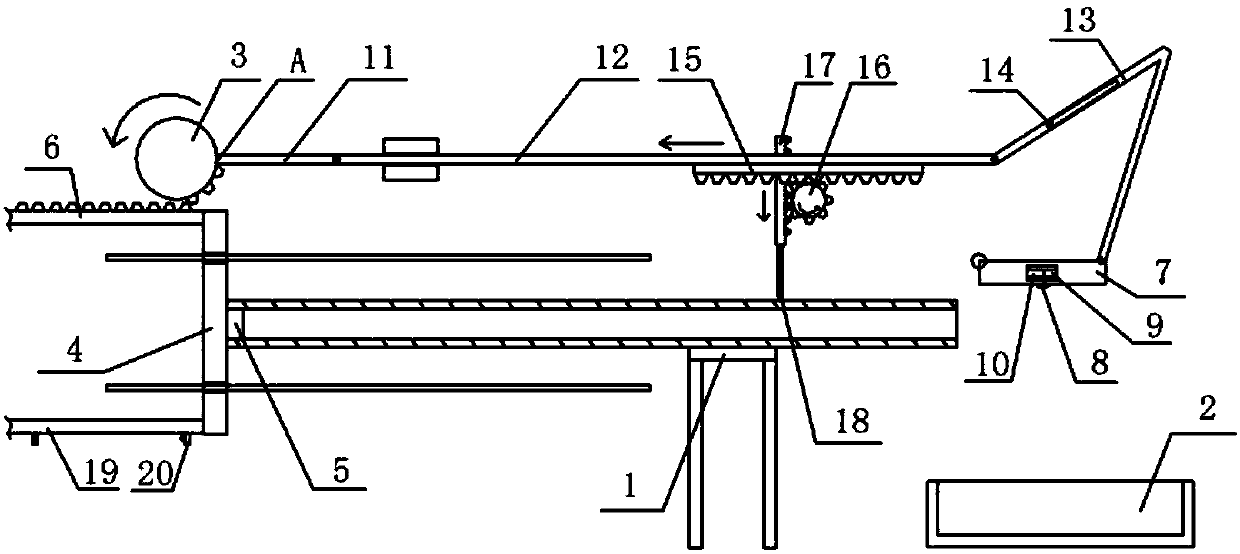

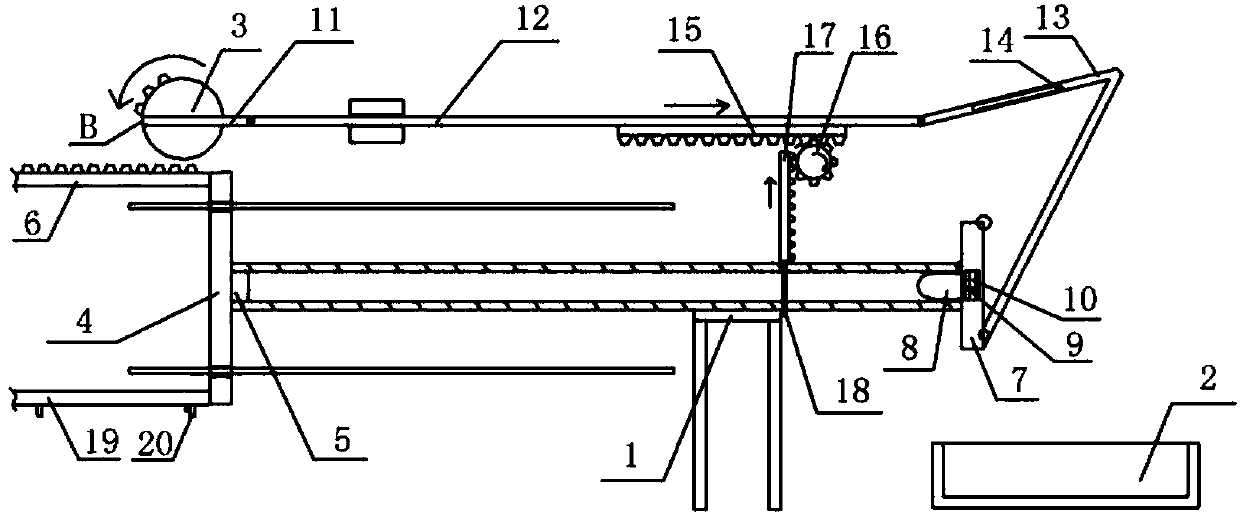

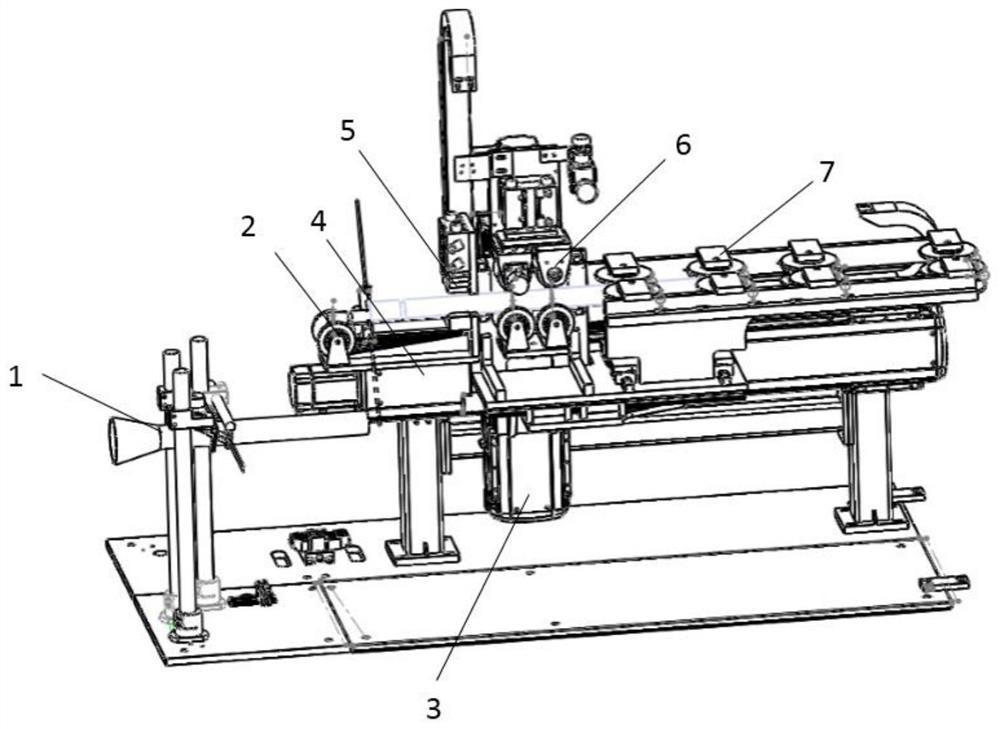

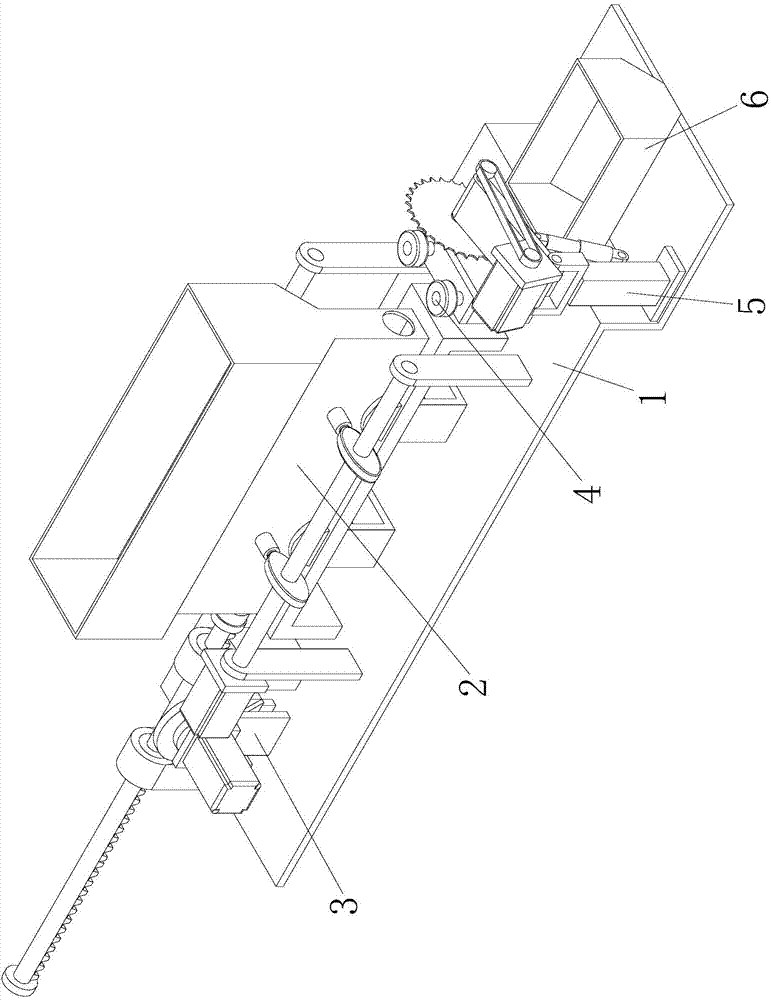

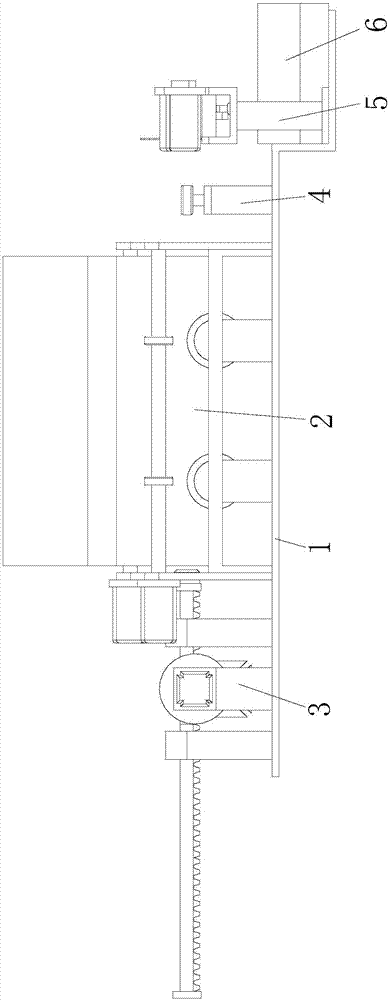

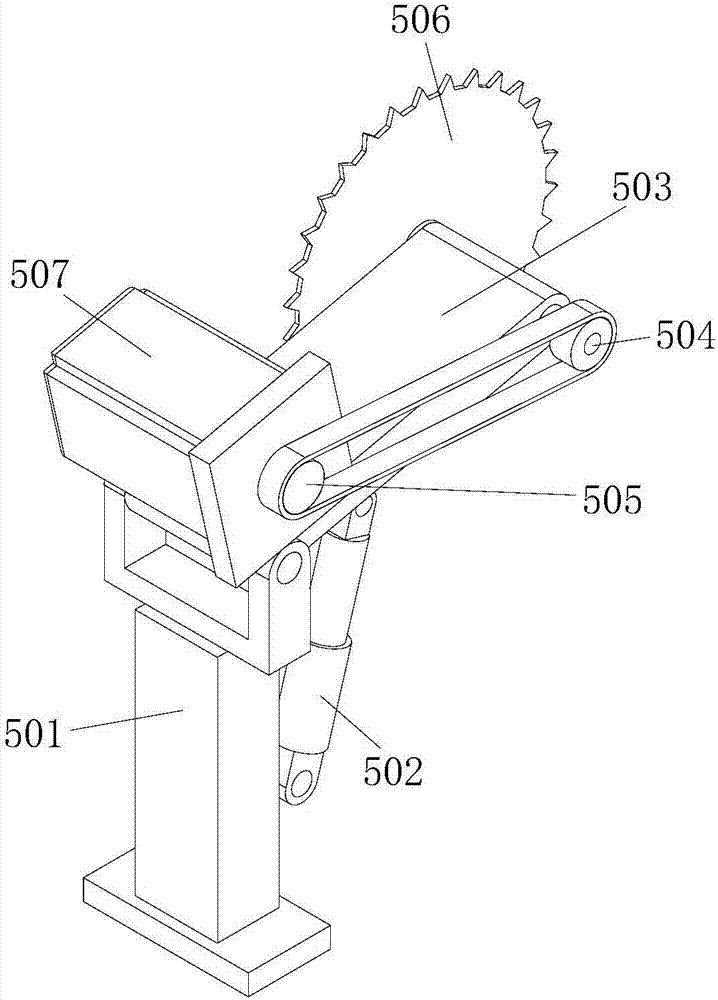

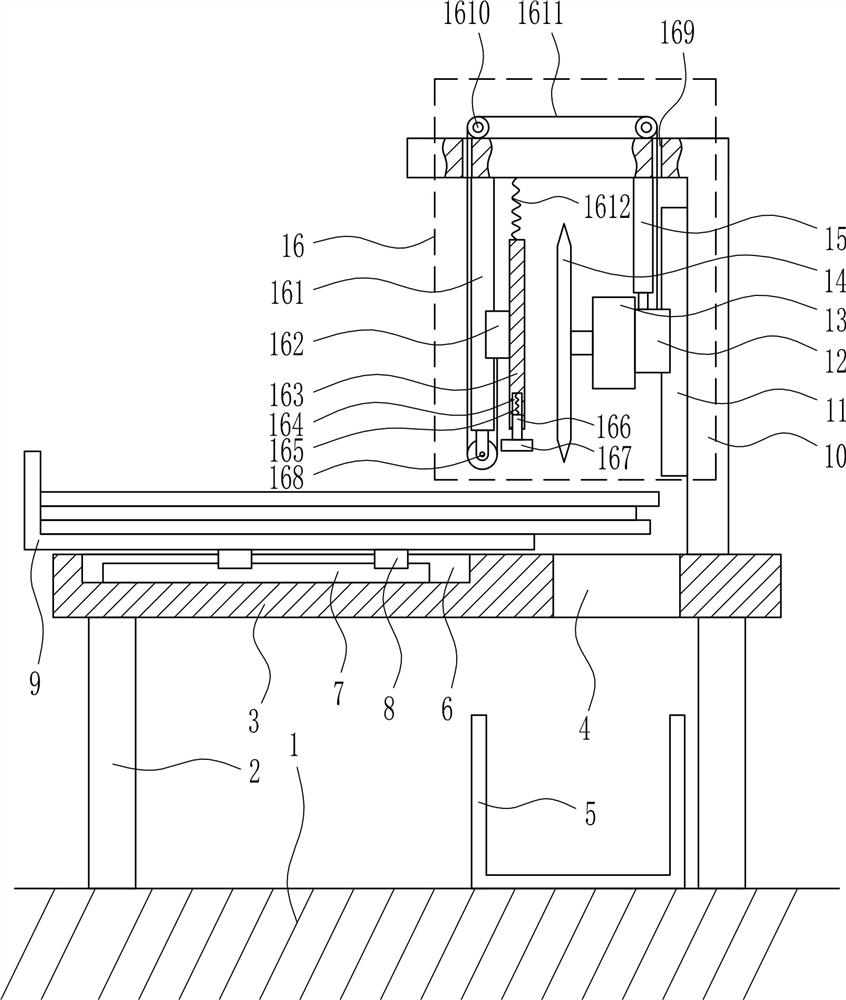

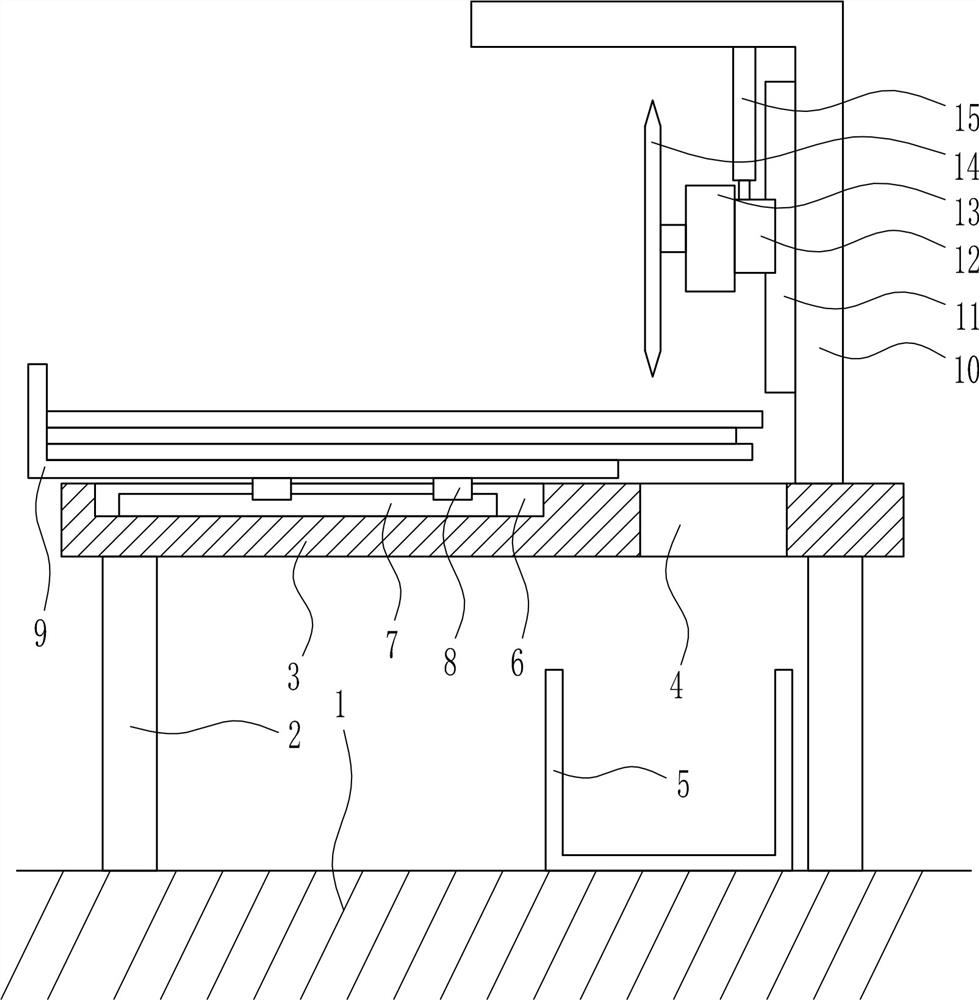

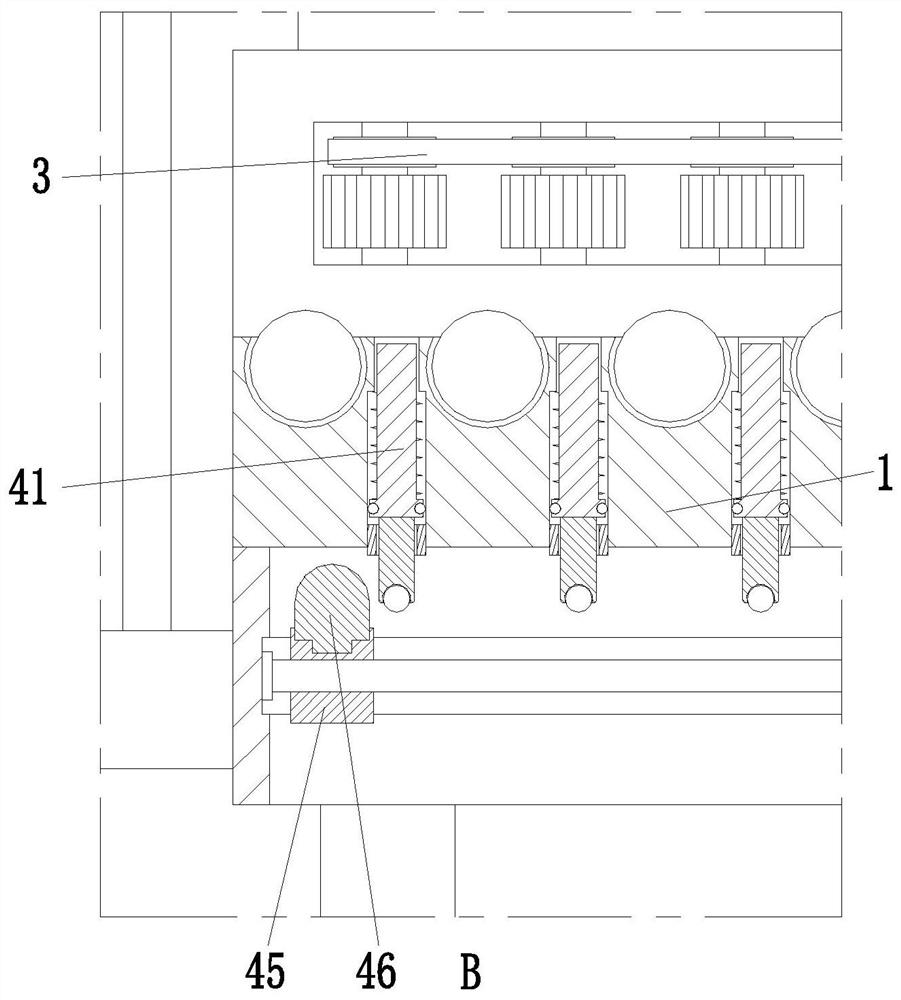

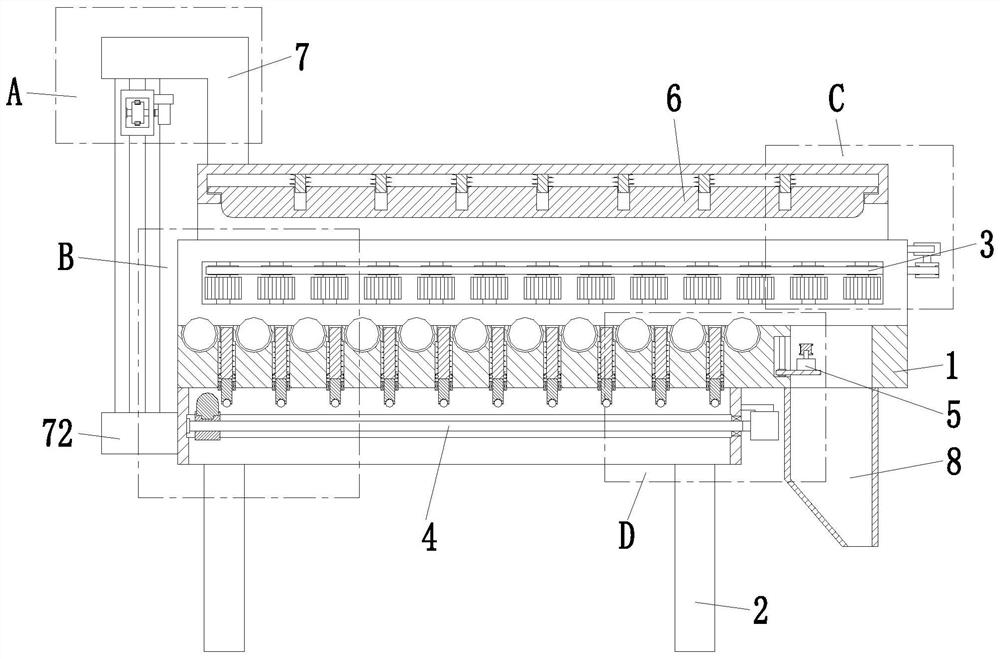

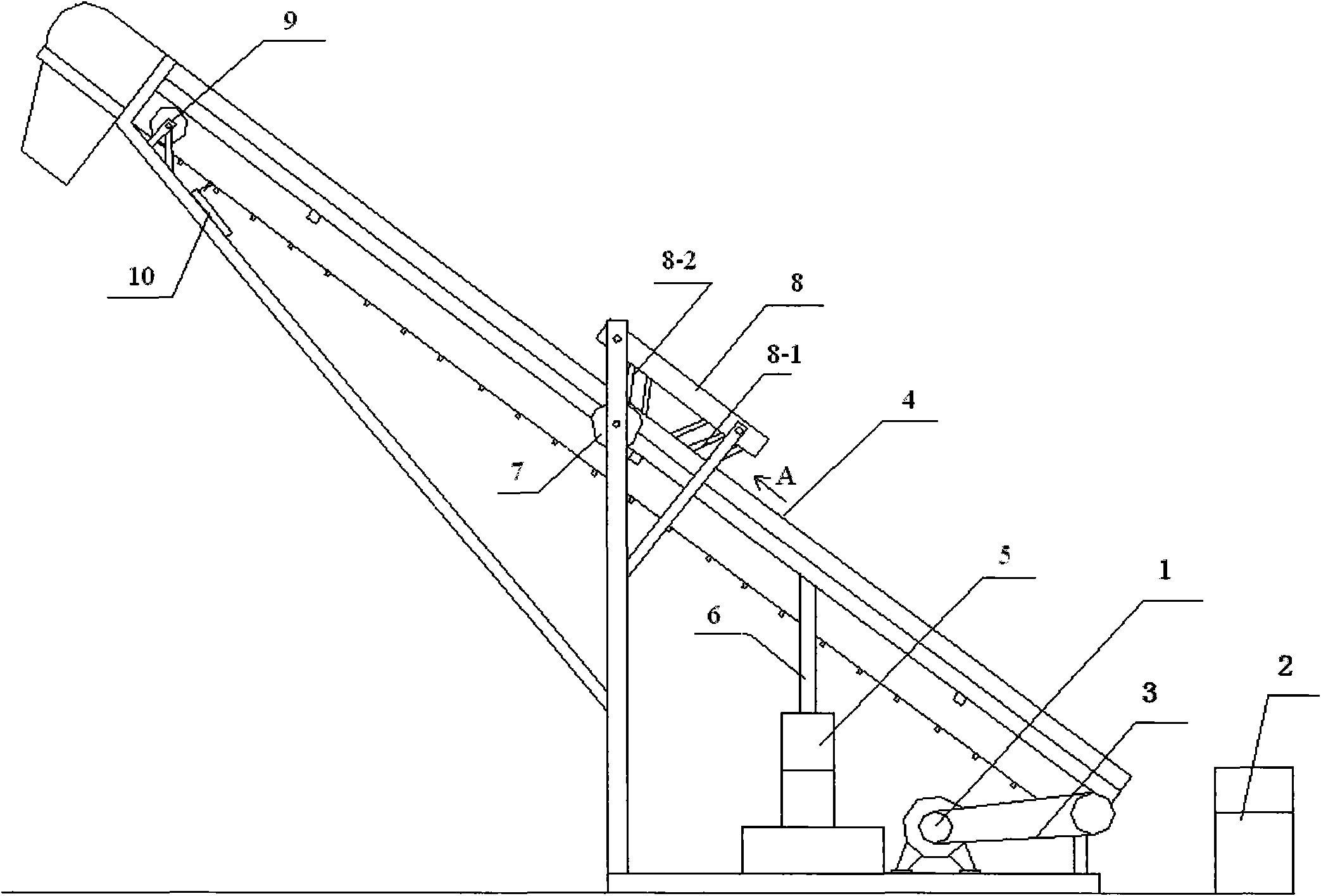

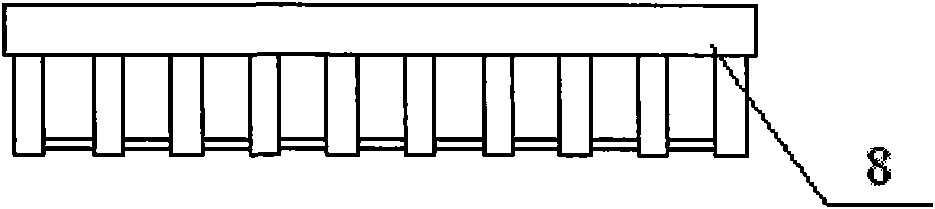

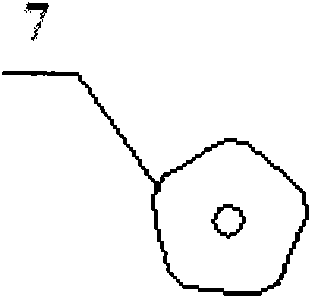

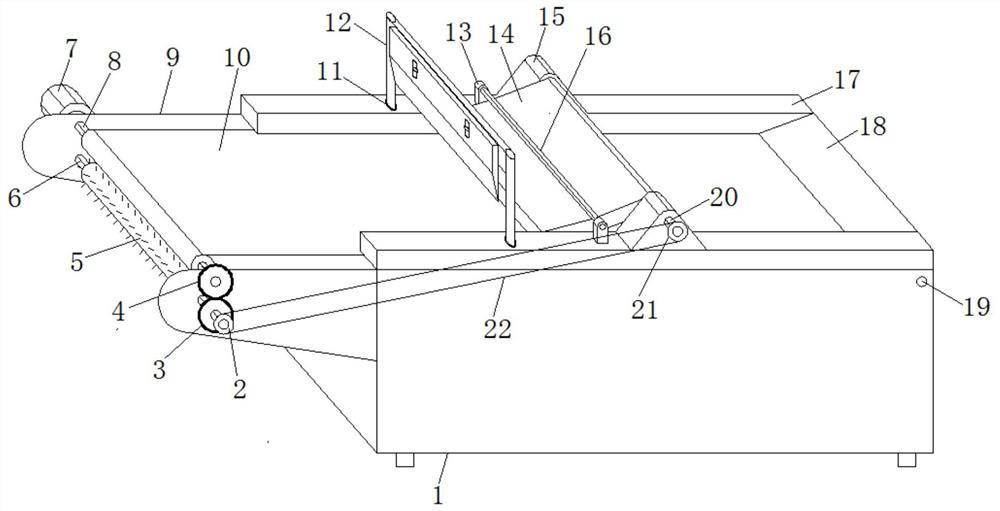

A feeding device for an electric heating tube

ActiveCN105269070BIncrease productivityReasonable structural designMetal sawing devicesMetal working apparatusHydraulic cylinderElectric machinery

The invention discloses a blanking device for electric heating pipes. The blanking device comprises a bottom plate, wherein a feeding device is mounted on the upper end surface of the bottom plate, and a push device is mounted on the front side of the feeding device; a limiter is mounted behind the feeding device and comprises a base, and limiting wheels are mounted at the left end and the right end of the base; a material storage tank is mounted behind the limiter, and a cutting device is mounted at the right end of the material storage tank and comprises a support frame; the left end of the support frame is articulated with a hydraulic cylinder, and the top end of the support frame is articulated with a long rod; a cutting motor is mounted on the long rod, a cutting shaft is mounted at the top end of the long rod, and a cutting blade is mounted at the left end of the cutting shaft. The blanking device has the advantages of being reasonable in structural design, low in production and manufacture cost and convenient to use, can automatically cut the electric heating pipes, replaces manual cutting, is high in degree of automation, improves the production efficiency of the electric heating pipes, and saves manpower and material resources. The push device is utilized to discontinuously push out the electric heating pipes, so that the uniform cutting length is ensured, and the cutting quality is ensured.

Owner:WUHU TAINENG ELECTRIC APPLIANCES

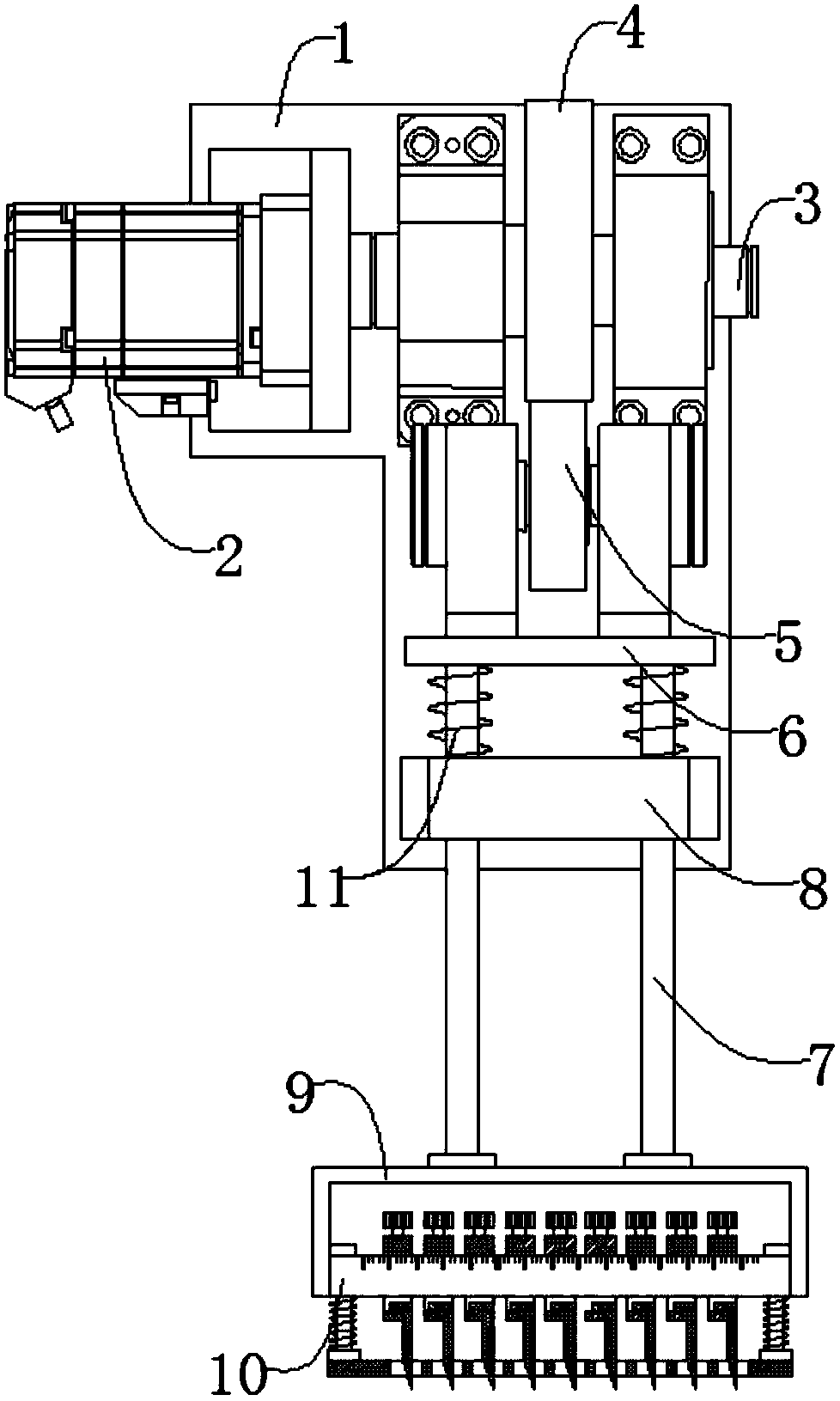

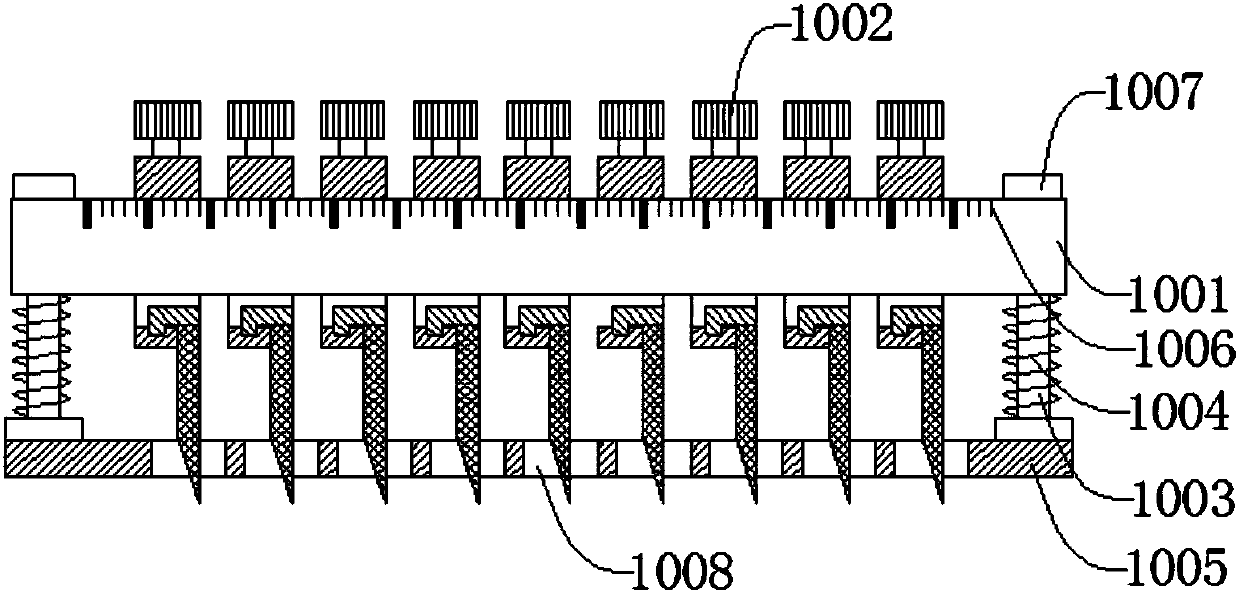

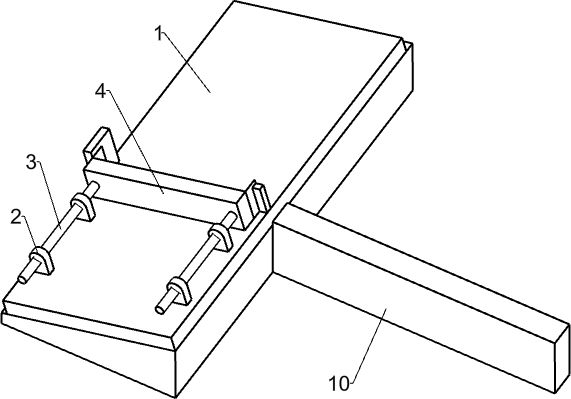

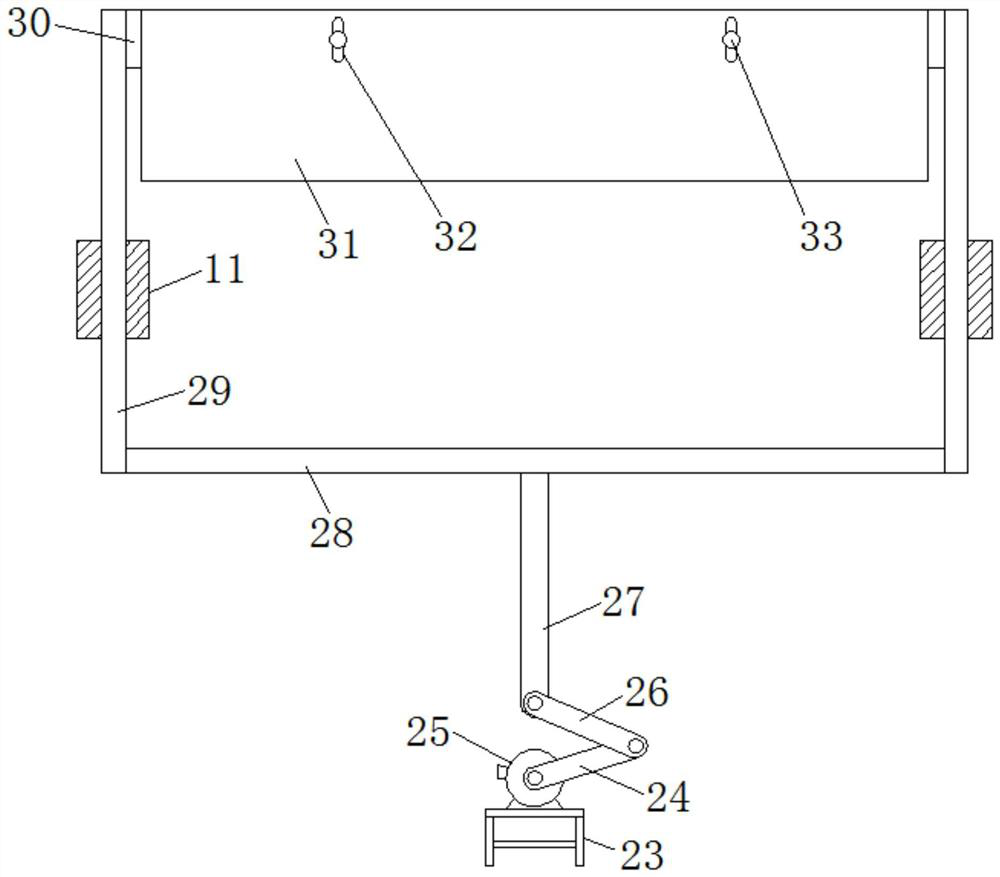

A device for simultaneous cutting of multiple planks for suspension bridge construction

ActiveCN108312237BEasy to cutFor precise cuttingGripping devicesClamping devicesArchitectural engineeringMechanical engineering

The invention relates to a cutting device, in particular to a simultaneous cutting device for a plurality of planks used in the construction of a suspension bridge. The technical problem to be solved by the present invention is to provide a simultaneous cutting device for multiple wooden boards for suspension bridge construction that can cut multiple wooden boards at the same time and have uniform cutting lengths. The invention provides such a device for simultaneously cutting a plurality of wooden boards for suspension bridge construction, which includes a support board, a first placing board, a collecting frame, a first slide rail, a first sliding block, a second placing board, a mounting frame, a second Slide rails, second sliders, etc.; left and right symmetrical support plates are arranged on the ground, a first placement plate is arranged on the top of the support plate, a first through hole is opened on the right part of the first placement plate, and the first through hole is placed on the ground below the first through hole. There are collection boxes. The present invention achieves the effect that multiple planks can be cut at the same time, and the cutting length is uniform. The present invention can lay flat through the second placing plate, which is convenient for cutting by the cutting wheel. The cutting is more precise.

Owner:广东捷标网信息科技有限公司

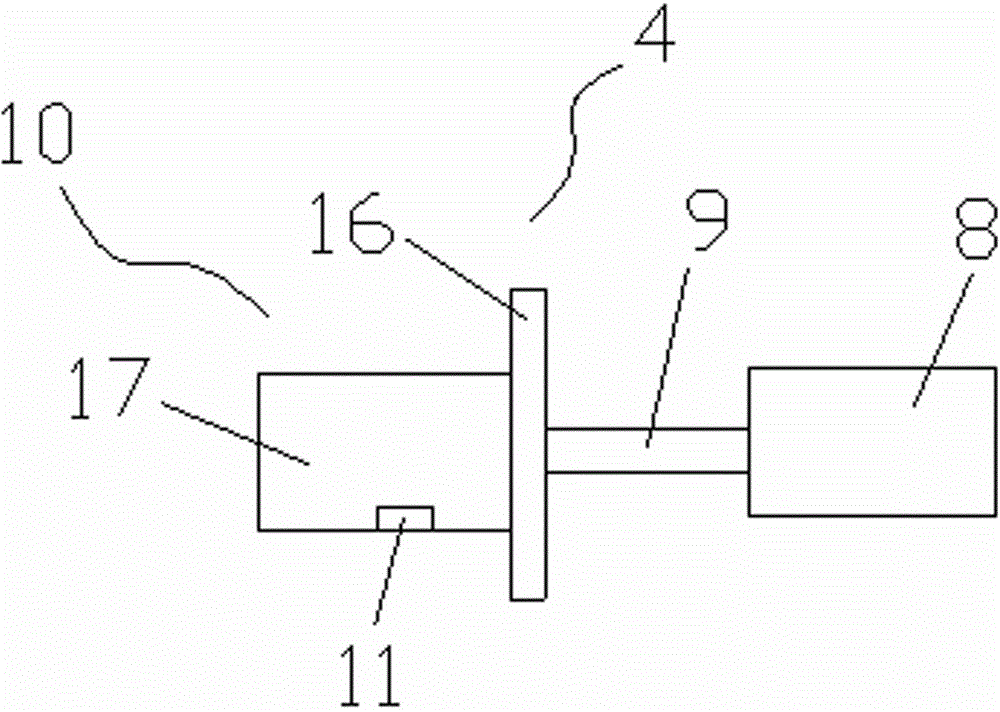

Reciprocating bean curd roll segmenting device

PendingCN107457808ASimple structureEasy to operateMetal working apparatusSoybean productAgricultural engineering

The invention belongs to the field of bean product processing, and in particular, relates to a reciprocating bean curd roll segmenting device. The device consists of a frame, a sensor, a cutter, a bean curd roll molding pipe and a reciprocating mechanism, and is characterized in that the sensor and a sensor fixed plate are fixed together; the sensor fixed plate is fixed on the frame; the cutter is fixed on the vertical side surface of the lower end of a cutter rest; the edge surface of the cutter is parallel to the axial end surface of the bean curd roll molding pipe, and forms a gap with the same; the horizontal surface at the lower end of the cutter rest is connected with the reciprocating mechanism; the reciprocating mechanism is connected with the frame; and the distance from the sensor to the section of the bean curd roll molding pipe determines the length of cut sections of bean curd rolls. The device has the characteristics of simple structure, convenience in operation, high production efficiency, uniform segmenting lengths and adaption to large-scale production.

Owner:HENAN JINPAI IND

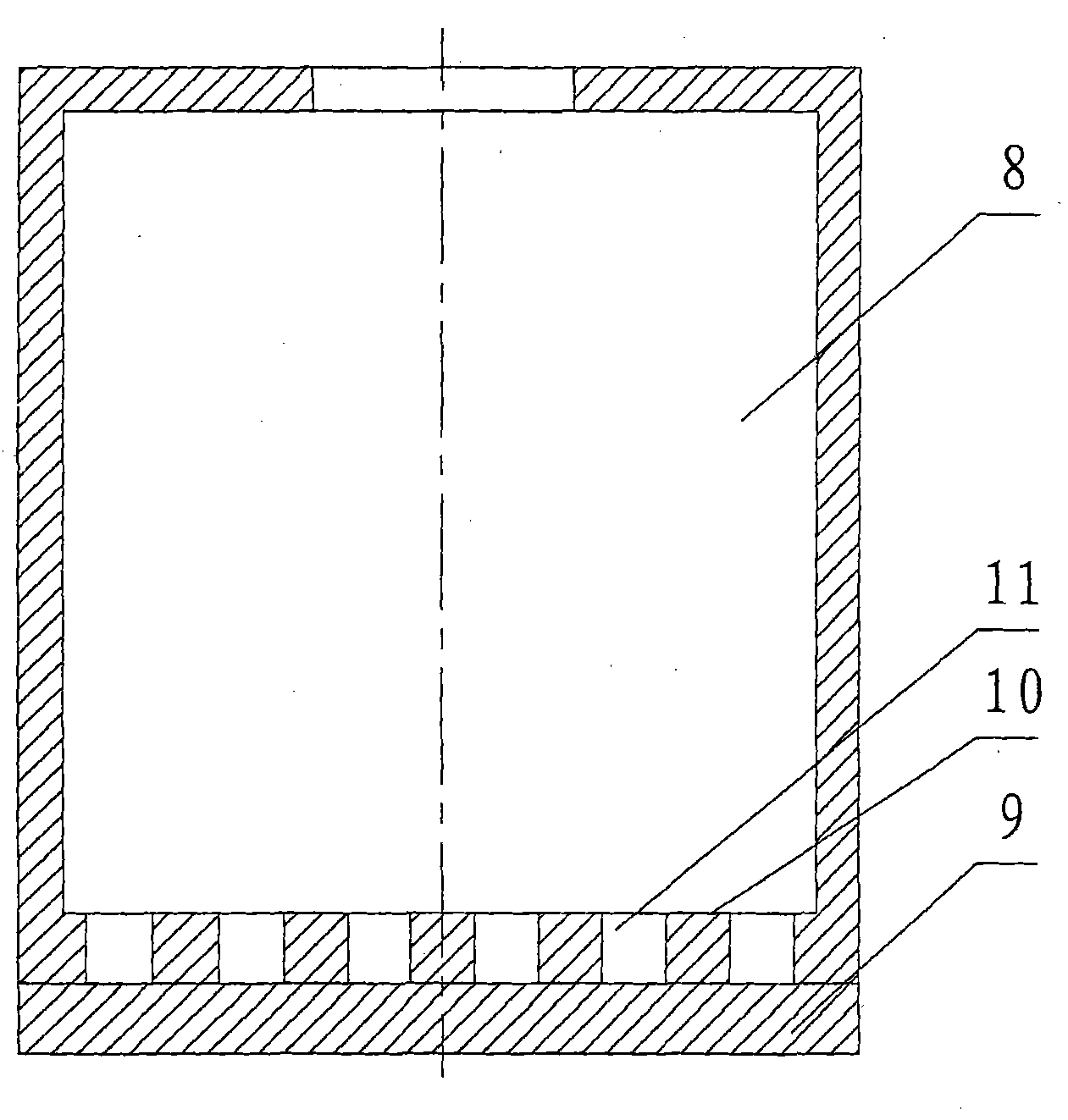

Process method for manufacturing steel shot by using bead wire of waste tire

InactiveCN102139471ASimple production processIncrease productivityAbrasive feedersEngineeringSteel belt

The invention relates to a process method for manufacturing steel shots by using bead wires of waste tires; the process method comprises the following steps: (1) wire dividing: each 6 to 7 bead wires of the tires with the diameters of below 1000mm are bonded in a row and then are added together layer by layer so as to form a circular ring formed by a multilayer steel belt, and the steel belt is formed by lengthwise unfolding the circular ring; the bead wires of the tires with the diameters of below 1000mm are lengthwise unfolded to form a single steel wire; (2) section cutting: the steel belt or the steel wire is fed into a special-purposed section cutting machine in a double-roll feeding mode and is cut into steel wire sections with consistent length; (3) degumming: a spiral feed extrusion machine is used for removing rubber adhered to the sections; (4) circle throwing: two-stage throwing is adopted during circle throwing; (5) the steel shots after the secondary throwing are sieved; and (6) packaging and storing. Metal abrasives produced by the process method have high quality and long service life and are suitable for cleaning and dust removal for the surfaces of various workpieces; and the production environment is safe and clean.

Owner:TIANJIN XINCHAO AST STEEL & ABRASIVE FOUNDRY

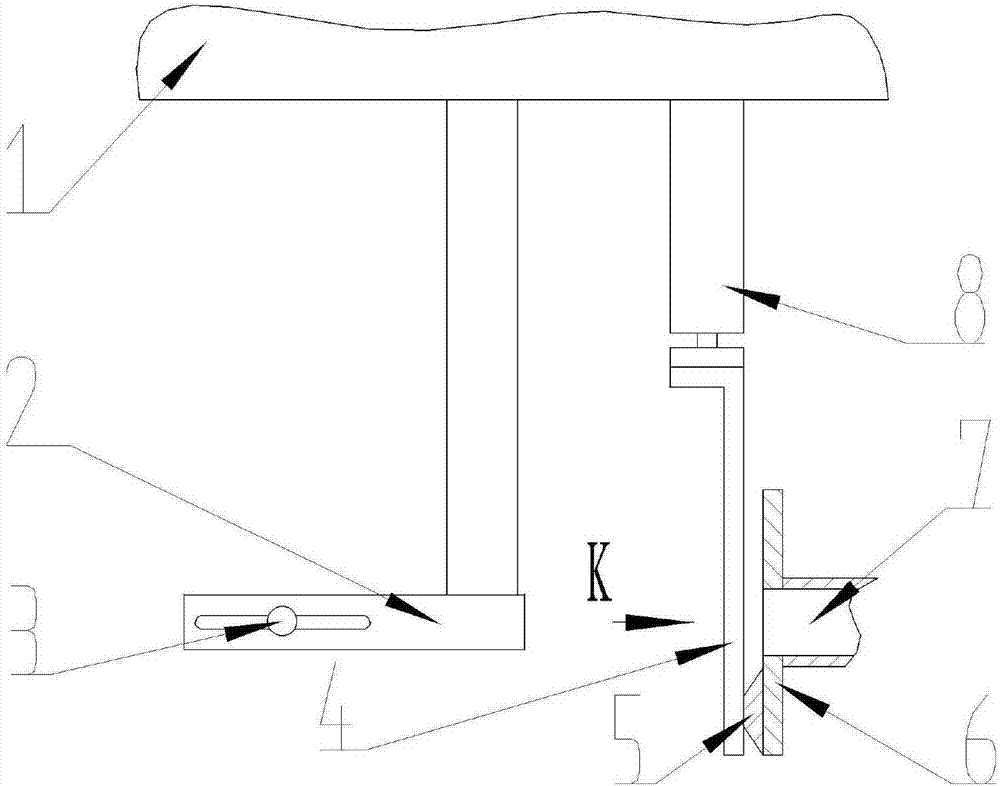

A kind of waste cable cut-off stripping device

ActiveCN111817215BEffective guidanceAvoid skewBasic electric elementsApparatus for removing/armouring cablesHydraulic cylinderEngineering

The invention relates to the technical field of waste and old cables, and discloses a waste and old cable cutting-type stripping device, which includes a bottom plate and a top plate, and a support column is fixedly installed between the top of the bottom plate and the bottom of the top plate, and the middle part of the two support columns on the right is A lead wire cover is fixedly installed between them, guide wheels are fixedly installed on the inner top wall and inner bottom wall of the lead wire cover, a cutting seat is fixedly installed on the top of the bottom plate, an L-shaped frame is fixed on the upper end of the left side wall of the cutting seat, and the L-shaped frame A sleeve pipe is fixedly installed at the top, a hydraulic cylinder is fixedly installed at the bottom of the top plate, a fixing seat is fixedly installed at the output end of the hydraulic cylinder, and a cutting knife is fixedly installed at the bottom of the fixing seat. The invention solves the problems that the existing waste cable stripping device has a simple structure, is easy to break during stripping, and is inconvenient to collect a whole cable stripping.

Owner:ANHUI ZHONGRUN CABLE GRP SHARES CO LTD

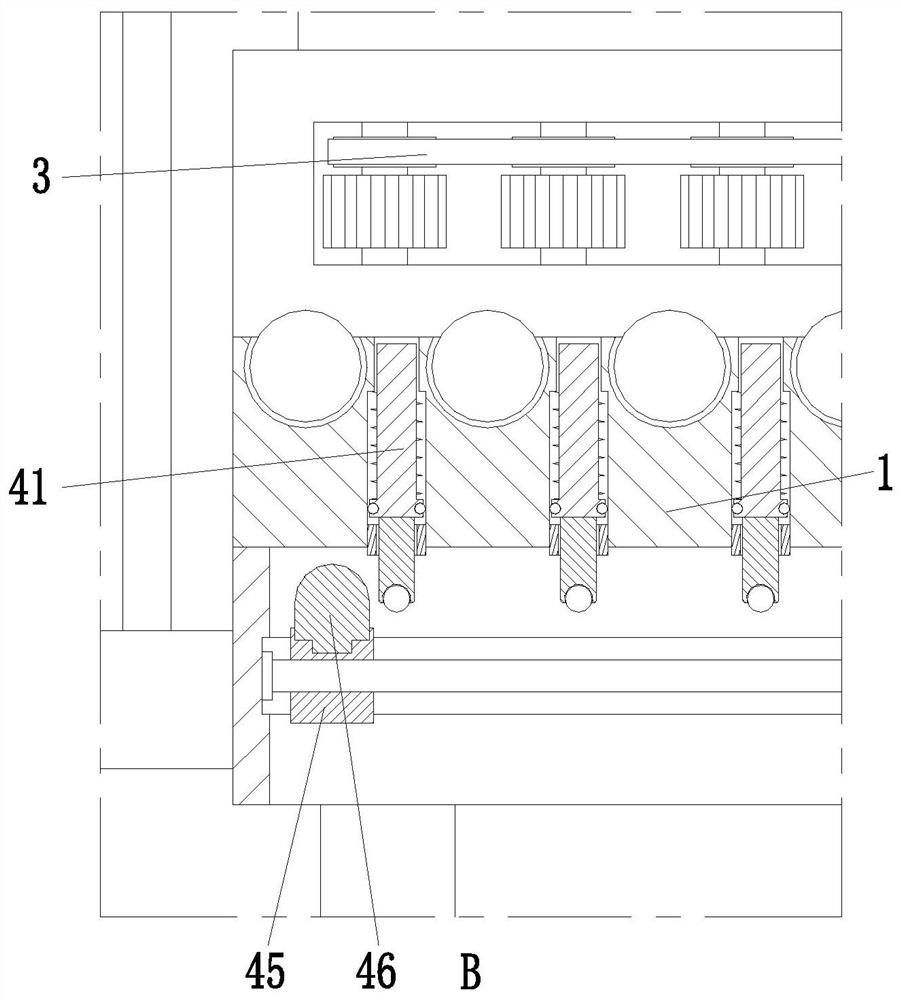

An automatic fixed-length cutting machine for pvc pipe

ActiveCN112388701BUniform cutting lengthRealize fixed length controlEdge grinding machinesMetal working apparatusLap jointMechanical engineering

The invention provides an automatic fixed-length cutting machine for pvc pipes, which includes a lap joint frame, a support rod, a moving device, a distance adjusting device, a grinding device, a limit device, a cutting device and a material guide pipe; In the process of fixed-length cutting, the cutting length of the pvc pipe is mainly uneven, which leads to the uneven length of the pvc pipe during installation and use, which makes it difficult to ensure the quality of the incision between the pipes, which in turn affects the installation and use of the pipes, and the existing cutting device has a During the cutting process of the pipe, it is difficult to keep the cut of the pipe flat, which affects the sealing performance of the pipe after installation and connection.

Owner:YANCHENG JIACHENG PLASTIC

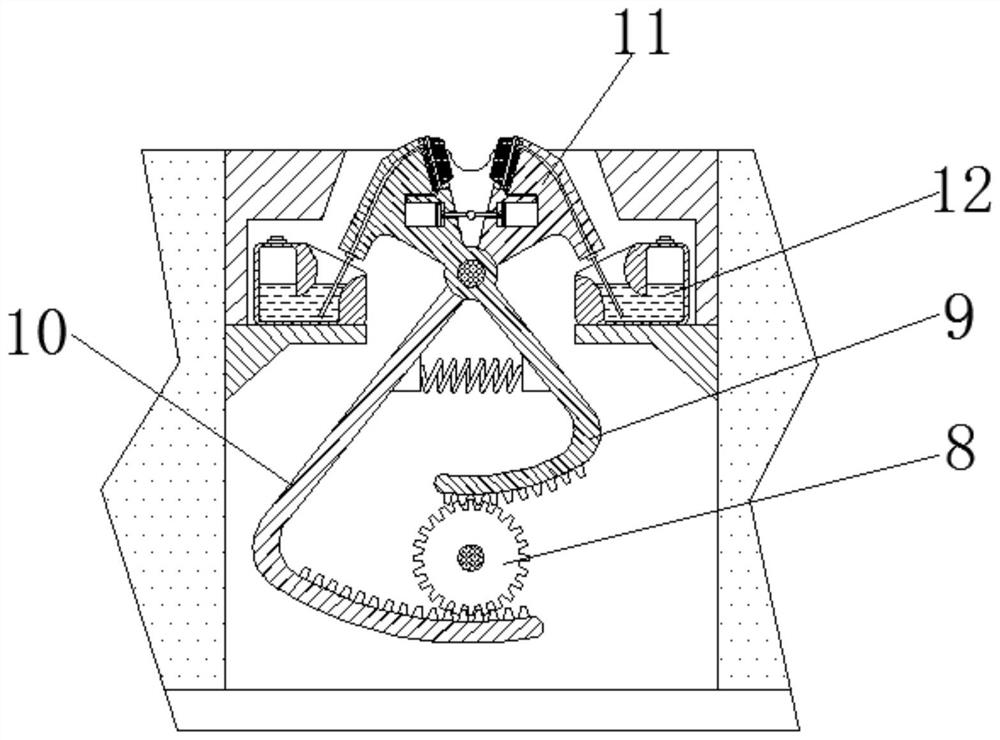

Shearing head of reinforcing steel bar batch shearing equipment for construction

InactiveCN112453276AUniform cutting lengthAchieve coolingMaintainance and safety accessoriesTool bitCrank

The invention relates to the technical field of reinforcing steel bar shearing equipment, and discloses a shearing head of reinforcing steel bar batch shearing equipment for construction. The shearinghead comprises a connecting seat, a mounting head is fixedly connected to the upper end of the connecting seat, a driving crank is arranged on the front side of the mounting head, a rack is movably connected to the tail end of the driving crank, a limiting sleeve sleeves the rack, and a shifting gear is arranged below the limiting sleeve and movably connected with a synchronous connecting rod. According to the shearing head of the reinforcing steel bar batch shearing equipment for construction, when shearing pliers are separated from the shearing position, a push rod connected between coolingpistons pulls the cooling pistons to generate negative pressure in a cavity, and a water drawing pipe absorbs water from a water tank and fills a coil pipe in a cooling groove to absorb heat generated by shearing reinforcing steel bars; and when a shearing wheel drives the shearing pliers to approach for shearing again, the push rod pushes the cooling pistons to extrude high-temperature cooling water, so that a high-temperature tool bit of the shearing plier is cooled through shearing action, and the service life of the tool bit and a fixing device thereof is prolonged.

Owner:黄婕妤

Automatic fixed-length cutting machine for PVC pipe

ActiveCN112388701AUniform cutting lengthGuaranteed cut qualityEdge grinding machinesMetal working apparatusGrindingLap joint

The invention provides an automatic fixed-length cutting machine for a PVC pipe. The automatic fixed-length cutting machine comprises a lap joint sleeve frame, a supporting rod, a moving device, a distance adjusting device, an opening grinding device, a limiting device, a cutting device and a material guide pipe. The automatic fixed-length cutting machine solves the problems that in the fixed-length cutting process of the PVC pipe, the cutting length of the PVC pipe is not uniform, so that the length of the PVC pipe is not uniform in the installation and using process, the notch quality between pipes is difficult to guarantee, installation and using of the pipes are affected, notches of the pipes are difficult to keep flat in the pipe cutting process of an existing cutting device, and therefore the sealing performance of the pipes after installation and connection is affected.

Owner:YANCHENG JIACHENG PLASTIC

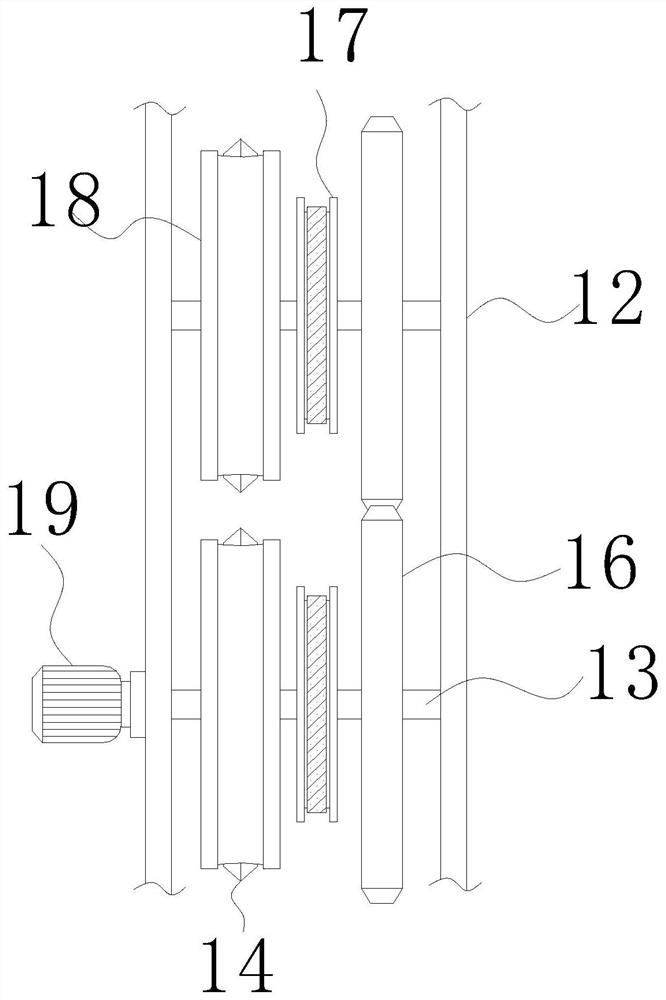

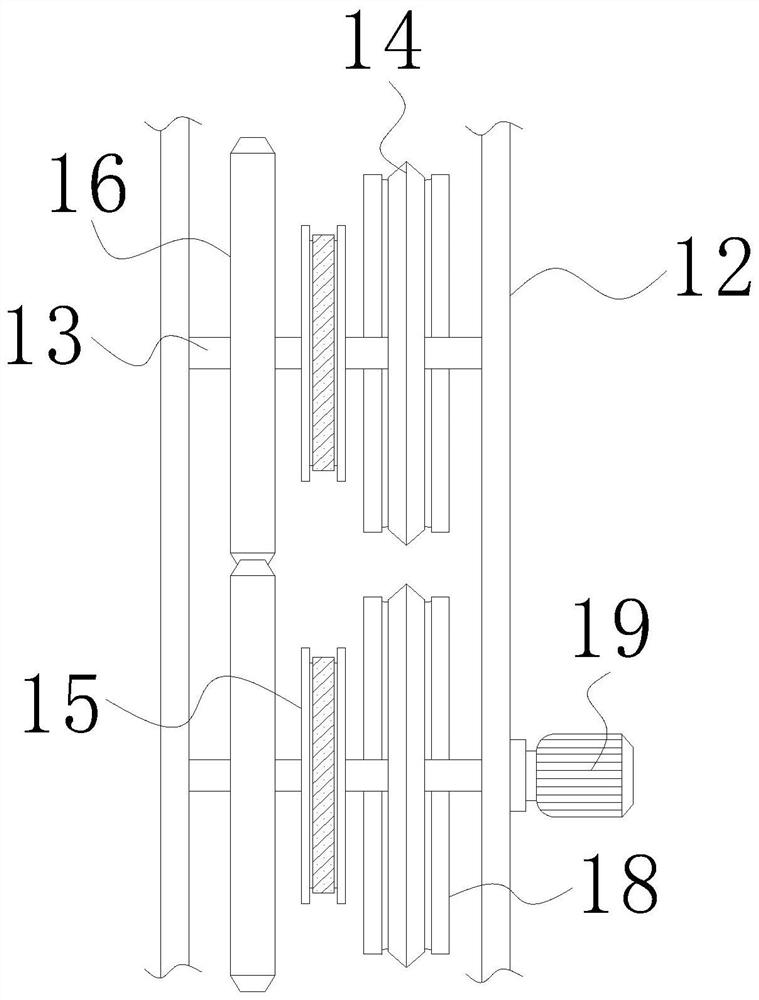

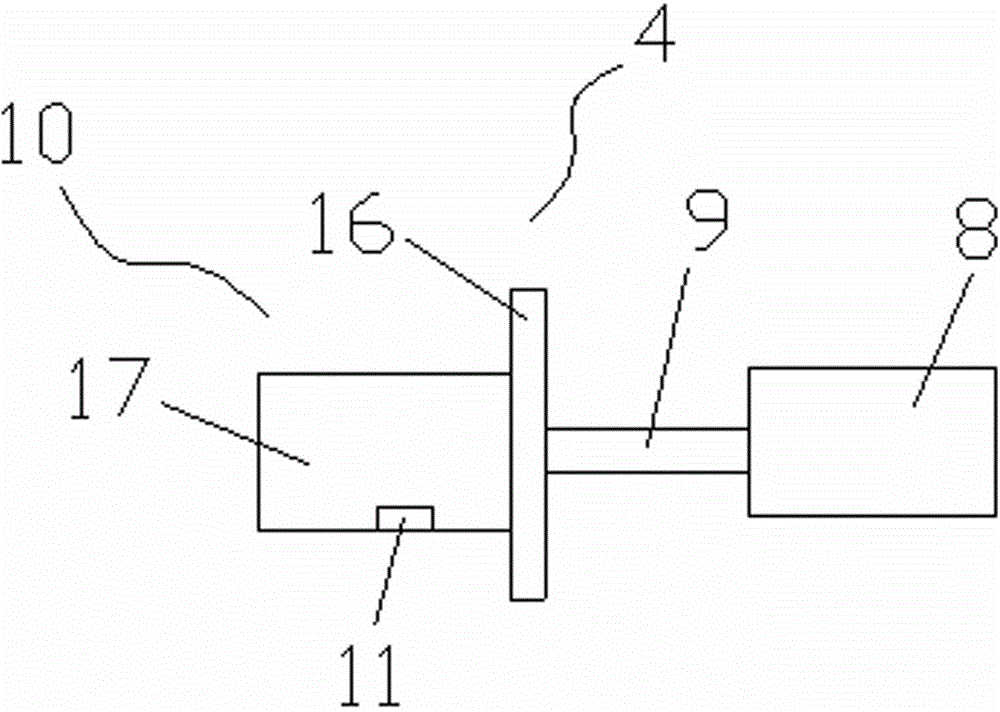

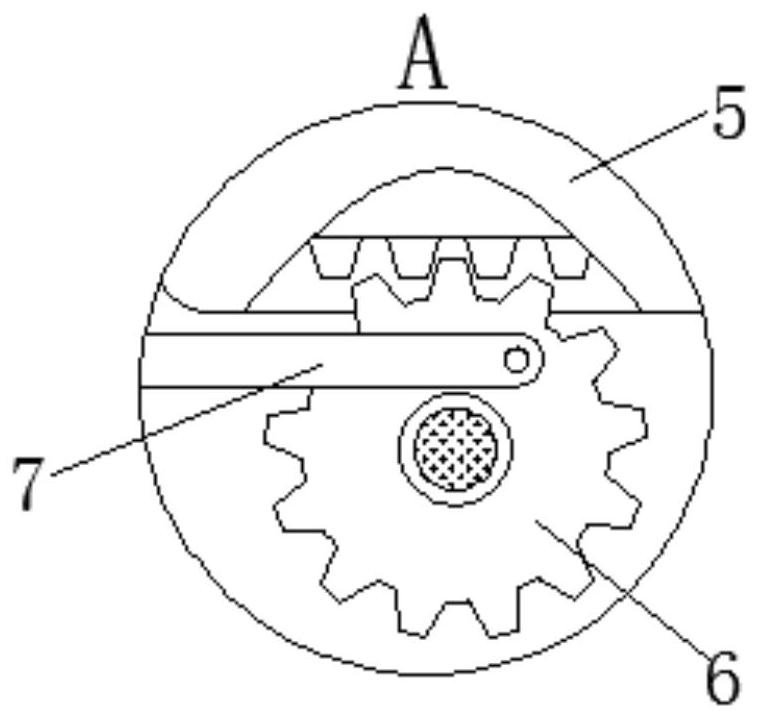

Transmission device capable of cutting fibrous raw material

ActiveCN101596725BUniform cutting lengthSmooth slidingMetal working apparatusMechanical engineeringRaw material

The invention discloses a transmission device, which is capable of cutting fibrous raw material and comprises a motor, a control device, a belt wheel and a track, wherein the control device drives the motor which drives the belt wheel; and the track covers the belt wheel and is characterized in that a hydraulic pressure device or a screw device is arranged below one end of the track and connectedwith the control device; a wave wheel is arranged below the track; a carding tool is arranged above the wave wheel and comprises two parts which are a comb at the front and a blade at the back; the blade is over against the wave wheel; an electromagnetic rotary drum is arranged below the other end of the track; and a brush is arranged below the electromagnetic rotary drum and contacted with the electromagnetic rotary drum. The transmission device transmits evenly, can automatically cut fibrous raw material into graininess and is beneficial to follow-up separation.

Owner:浙江省机电设计研究院有限公司

Cutting device for cloth processing

InactiveCN112144265ANeatly croppedUniform cutting lengthSevering textilesElectric machineryEngineering

The invention discloses a cutting device for cloth processing. The device comprises a main body; a working cavity is formed in the main body; an upper supporting rod and a lower supporting rod are fixedly installed on the upper end wall and the lower end wall of the working cavity respectively; conveying assemblies are symmetrically arranged on the front side and the rear side of the upper supporting rod; each conveying assembly comprises lifting grooves formed in the lower end wall of the working cavity in a front-back symmetrical mode; and lifting blocks connected with the lower end walls ofthe lifting grooves through lifting springs are arranged in the lifting grooves in a sliding mode. Clamping blocks on the upper side and the lower side are matched to pull cloth leftwards, the clothis stretched towards the front side and the rear side while being pulled leftwards to be flat, meanwhile the cut cloth is pushed leftwards into a discharging cavity, and after the cloth is pulled to the leftmost side, a cutting motor in a cutting block is started to drive the cutting block to slide backwards to cut the cloth.

Owner:玉环市迈远针织有限公司

A kind of bean curd stick that can be soaked quickly and its preparation method

The invention discloses a production method capable of quick soaking. The steps are as follows: step 1, making pulp, putting soybean milk in a pot to boil, and continuing to boil the soybean milk for 20 minutes after boiling; After boiling for 20 minutes, remove the skin for the first time, and then remove the skin every 10-15 minutes; step 3, bake, bake the soybean milk skin uncovered in step 2 at 100°C, and use it after drying The high-temperature steam softens the bean curd stick, cuts the bean curd stick into short strips to obtain the bean curd stick that can be soaked quickly. The bean curd stick of the present invention can be soaked for 10 minutes after being covered and soaked until softened, and can be eaten as soon as one wants to eat without soaking in advance, and is convenient to eat.

Owner:江西高安市惠而美食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com