Large-core-diameter wire harness user-defined cutting and rolling equipment

A self-defined, large core diameter technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of low work efficiency, high labor intensity, waste of cable raw materials, etc., and achieve uniform cutting length , increase work efficiency, improve the effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are intended to illustrate the invention, but not to limit the scope of the invention.

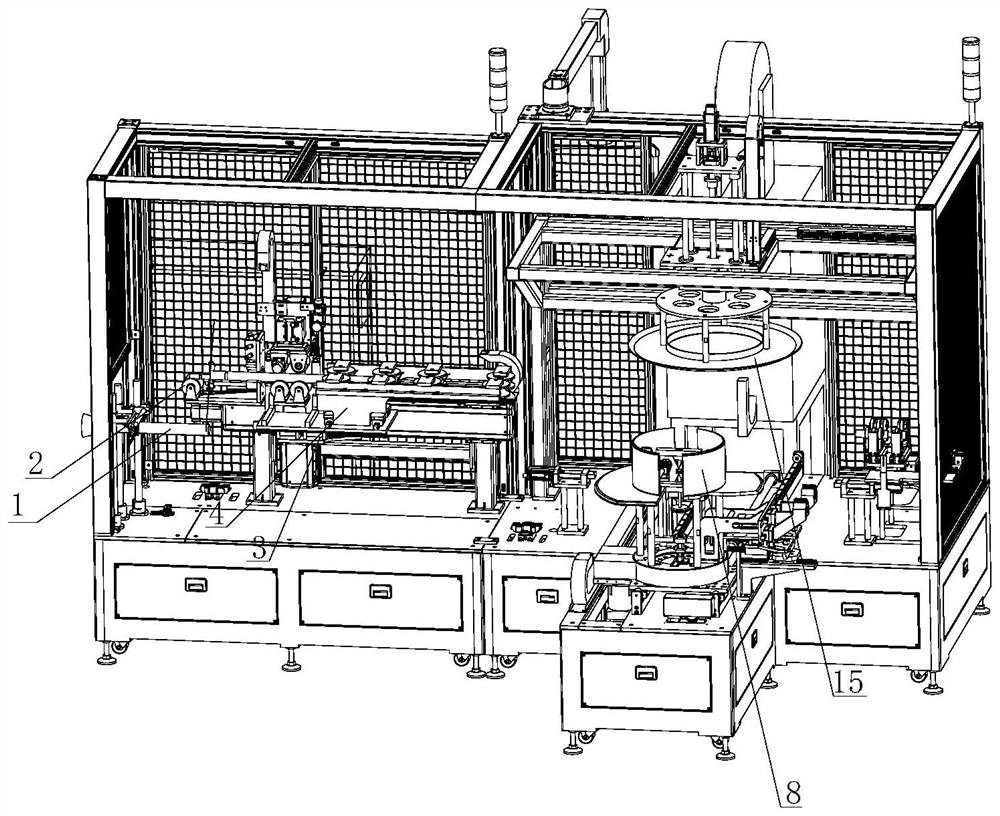

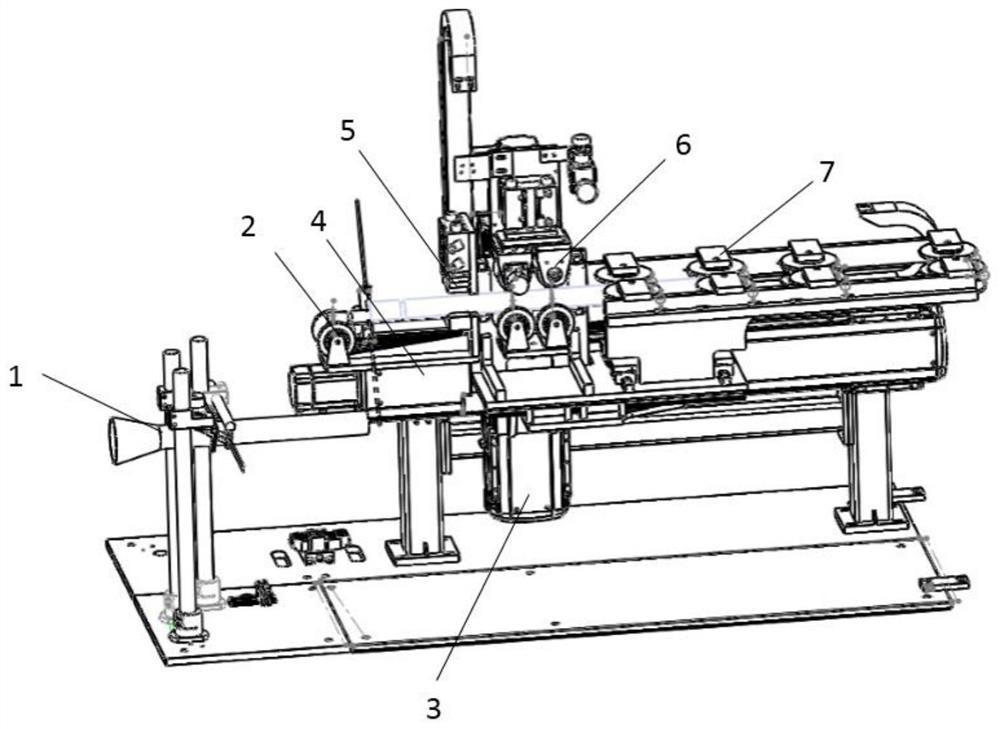

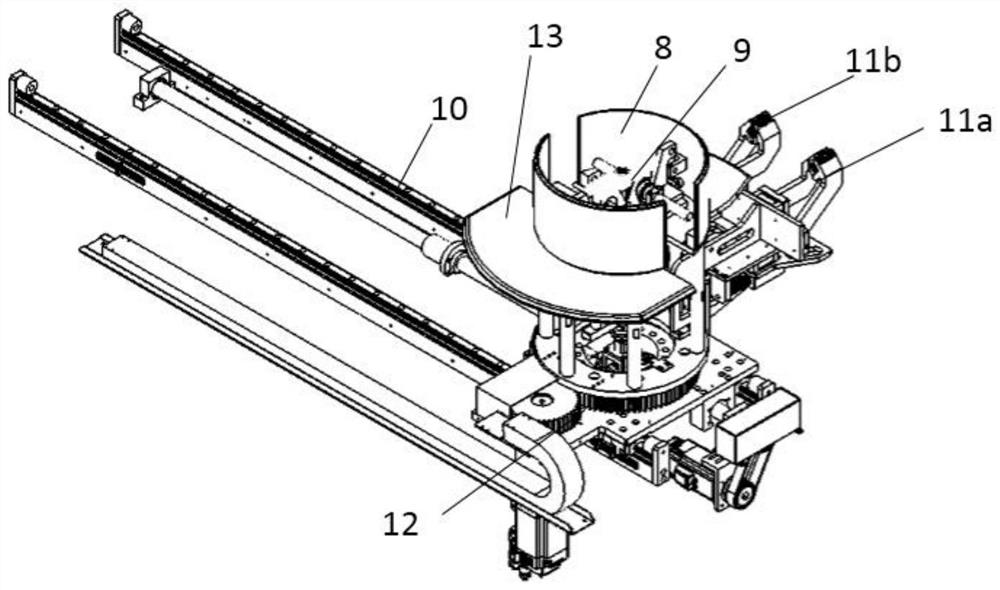

[0020] Such as Figure 1 to 5 As shown, a large core thread harness of the present invention is defined, including machine, robot, wirework mechanism, winding packaging, and upper rotating mechanism, wiring mechanism, winding packaging, and upper rotating mechanism. Installed on the machine; the wires include a rack, an adapter mechanism 1, a roller 2, a first slide module 3, a second slider module 4, a brake 5, a glue roller 6, a guide roller 7 And the sensor, the rack is mounted on the machine, and the adapter mechanism 1 is mounted on the rack, the first slide module 3 is mounted on the rack, the second slider module 4 is installed in the first slide module 3, the roller 2 is mounted on the rack, and the brake 5 is mounted on the second slider module 4, the sensor is fixed by the brake 5, and the inclusion roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com