Transmission device capable of cutting fibrous raw material

A technology of transmission device and cutting fiber, which is applied in metal processing and other directions, can solve the problems of inability to adjust the transmission angle, single function of the transmission device, and no way to eliminate it, and achieve the effect of uniform sliding, uniform transmission and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

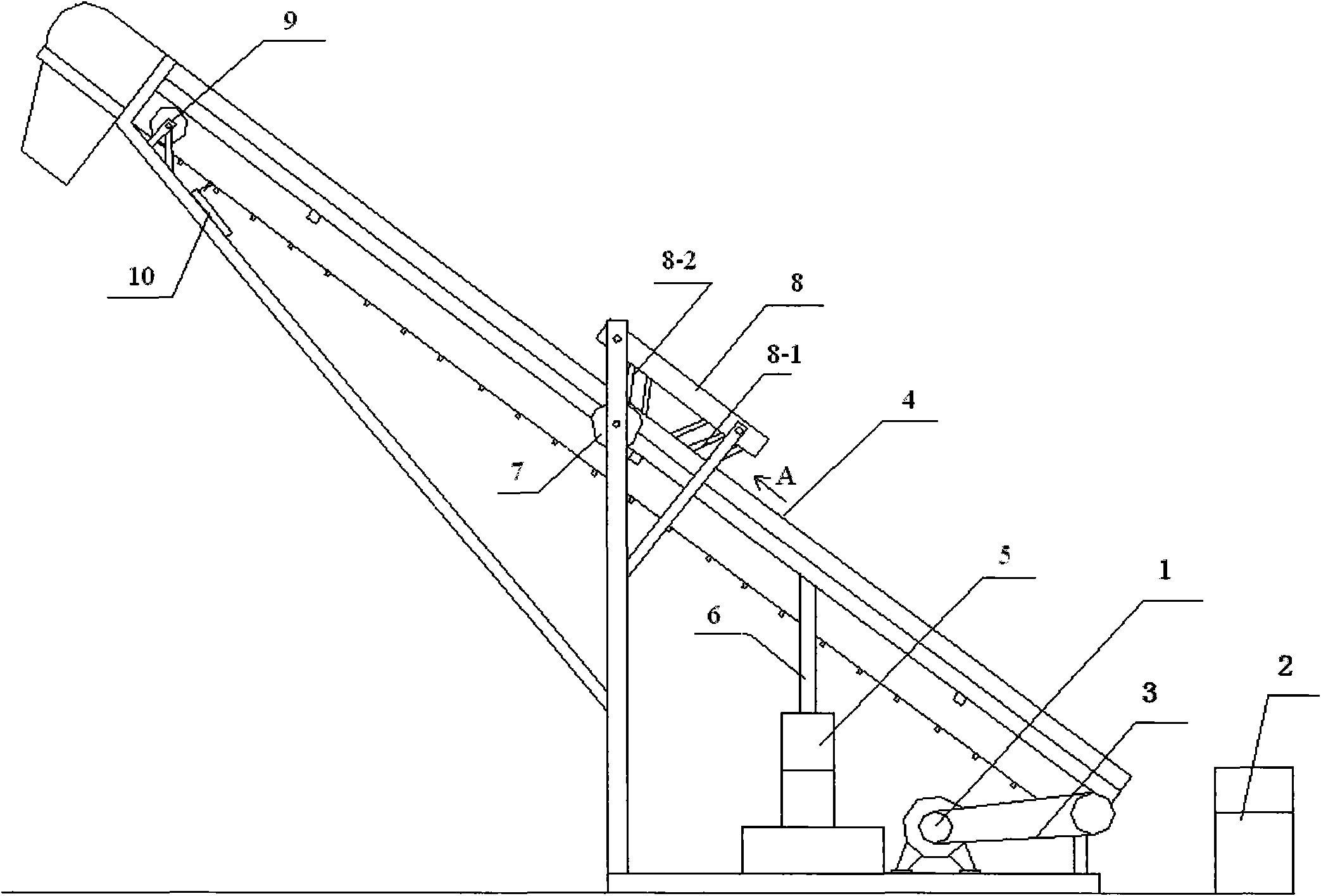

[0014] see figure 1 , figure 2 and image 3 , the present invention comprises motor 1, control device 2, pulley 3, crawler belt 4, and control device 2 is single-chip microcomputer, and control device 2 drives motor 1, and motor 1 drives pulley 3, and crawler belt 4 is coated on pulley 3, and crawler belt 4 is arranged below one end. There is a hydraulic device 5, the hydraulic device 5 is connected with the control device 2, the ejector rod 6 of the hydraulic device 5 is connected with the crawler belt 4, and the inclination angle of the crawler belt 4 can be adjusted, and the angle α between the crawler belt 4 and the horizontal plane ranges from 0 to 60 degrees. When the track is inclined, the items on the track slide down layer by layer and gradually separate, making the distribution of items on the track more even.

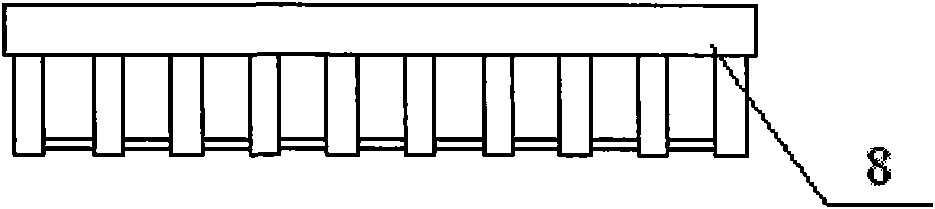

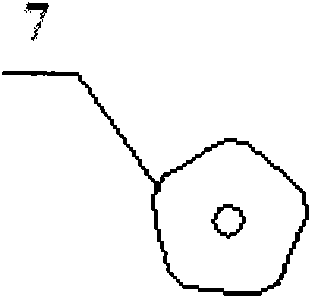

[0015] A wave wheel 7 is provided below the middle section of the crawler belt 4, and a comb knife 8 is provided at a position above the crawler belt 4 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com