Process method for manufacturing steel shot by using bead wire of waste tire

A technology of waste tires and process methods, which is applied in the direction of manufacturing tools, metal processing equipment, abrasive material feeding devices, etc., and can solve the problems of unstable surface cleaning quality of metal workpieces, environmental pollution by manual processing methods, and different lengths of cut sections. , to prevent dust from polluting the environment, not easy to break, and improve the quality of steel shot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

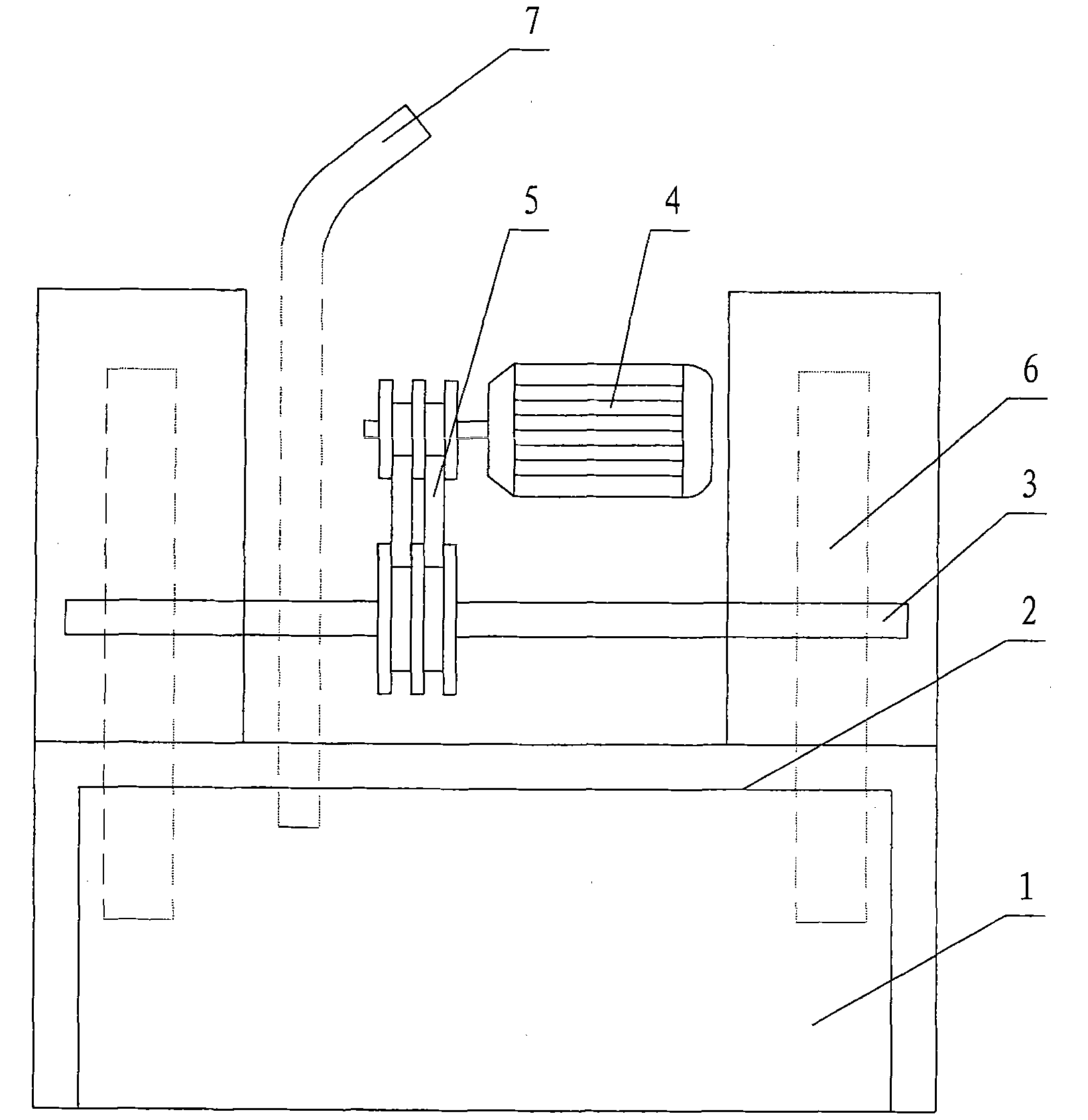

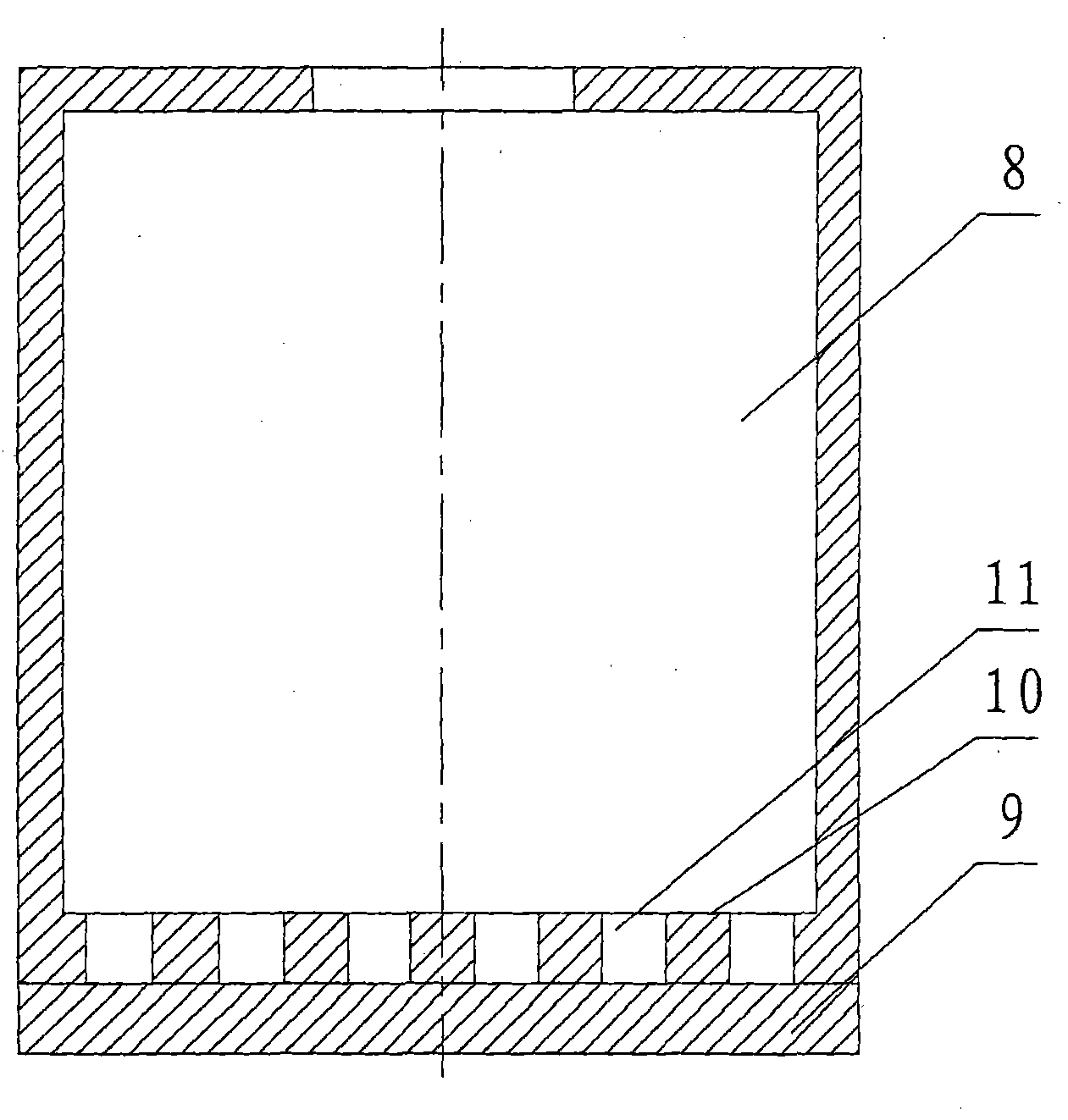

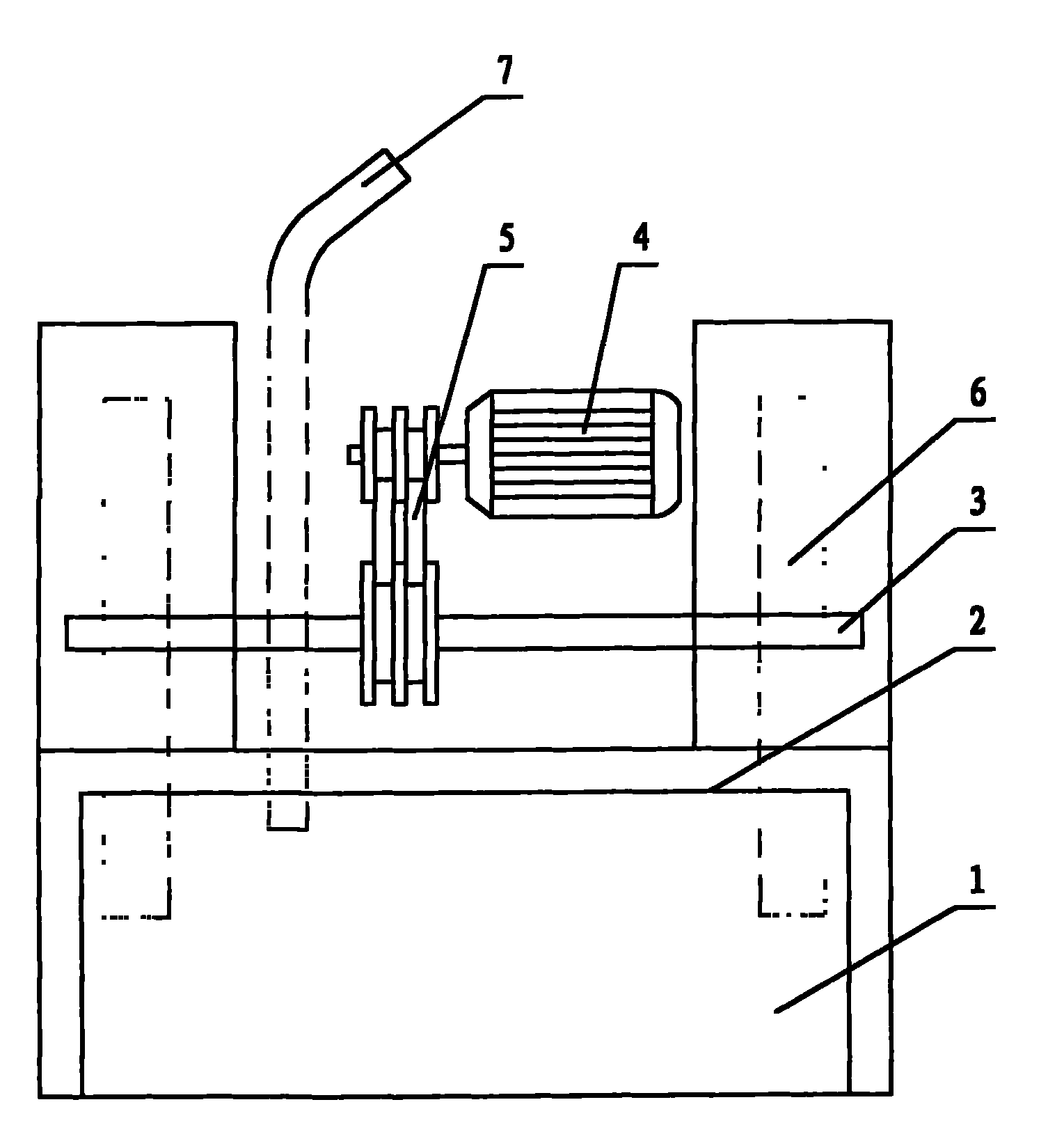

[0022] A process method for making steel shots using waste tire bead wires, according to the following steps: ①Splitting: For tires with a diameter of less than 1000mm, glue every 6-7 bead wires into a row, and then Layers of layers are added together to form a ring composed of multiple steel belts. Unfold it longitudinally to form a steel belt; for tires with a diameter of more than 1000mm, unfold the bead wire longitudinally into a single steel wire; ② Cutting section: Feed the steel strip or steel wire into a special cutting machine to cut the steel wire with uniform length and length; ③Gluing: Use a screw extruder to remove the rubber attached to the cut section , After winnowing, a pure steel wire cut section is obtained; ④ Rounding: Two-level polishing is used when rounding: One-level polishing: Put the clean steel wire section into the rounding machine at a speed of 65-75 m / s The speed is repeatedly thrown for 20-30 minutes to remove the flash and burr of the cut section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com