Cloth cutting machine

A cutting machine and fabric technology, applied in sewing machine components, textiles and papermaking, garment piece transporters, etc., can solve problems such as affecting work efficiency, unstable work, and many mechanical failures, and achieve improved work efficiency, stable and reliable operation. The effect of reducing business costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

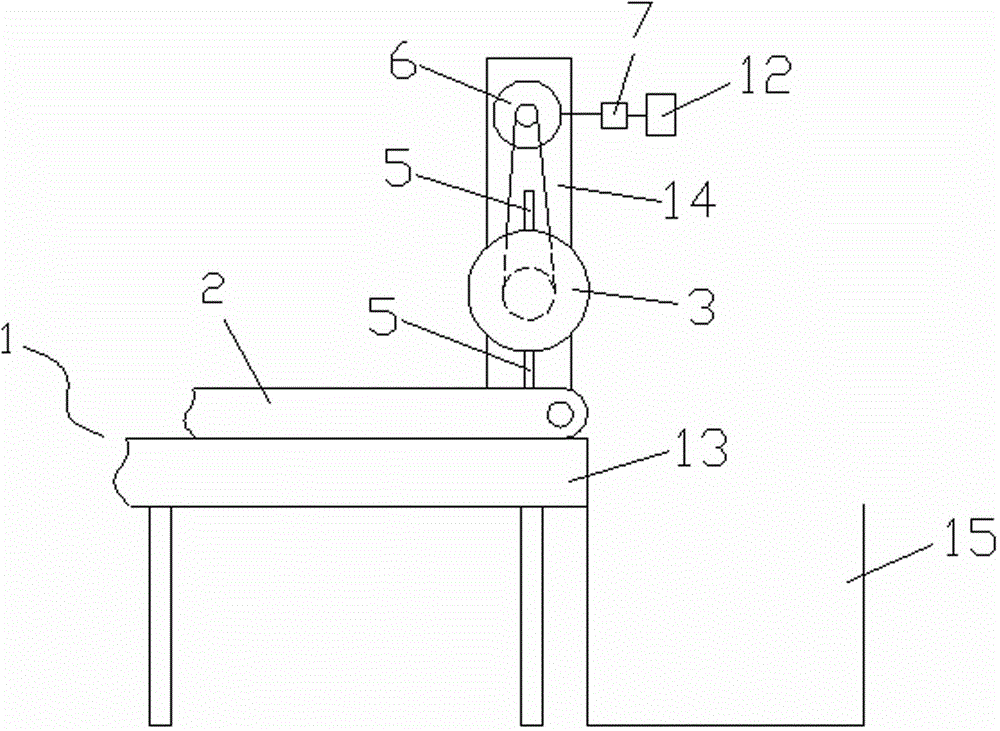

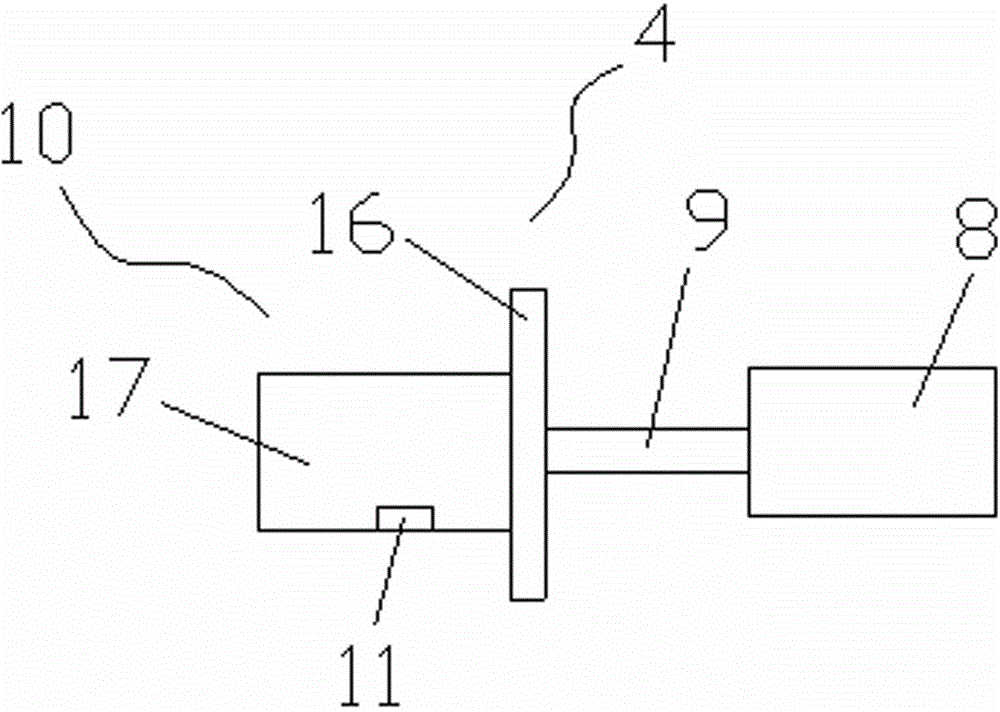

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0017] Such as figure 1 , figure 2 As shown, a cloth cutting machine includes a frame 1 and a transmission mechanism 2 installed on the frame 1. The preferred transmission mechanism 2 of the present invention is a belt transmission mechanism, which is simple and convenient. The frame 1 is also provided with a cutter head 3 , limit device 4, cutter head 3 is positioned at the top of transmission mechanism 2, at least two cutting knives 5 are evenly fixed on the peripheral surface of cutter head 3, and the middle part of cutter head 3 is connected with a motor 6, in order to adjust the rotation of cutter head 3 speed, to realize the cutting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com