Easy-to-adjust refrigerator backplane blanking device

A back plate and punching technology, applied in the application field of punching equipment, can solve the problems of limited model and narrow punching range, etc., and achieve the effect of adjustable cutting length and expanding working range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

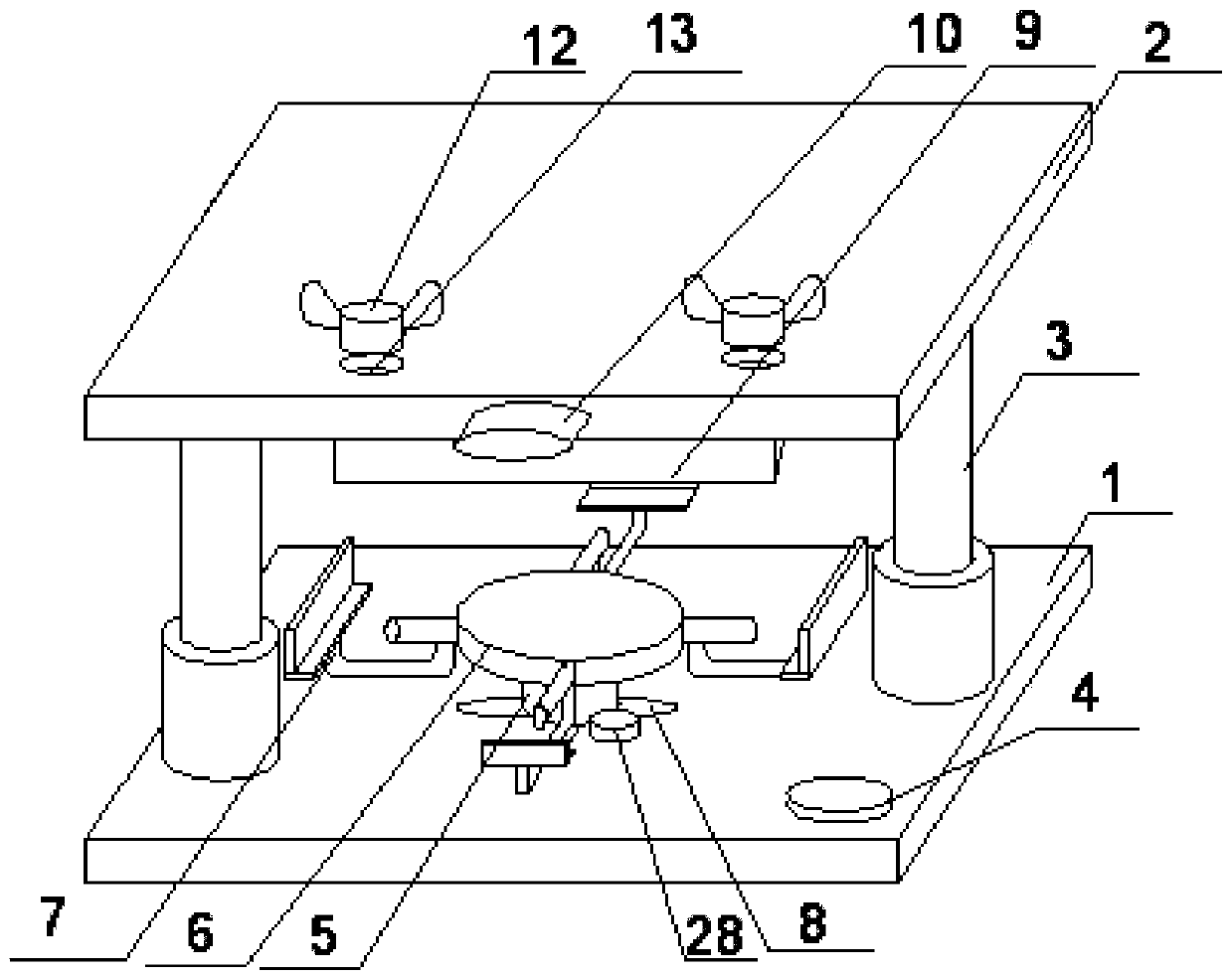

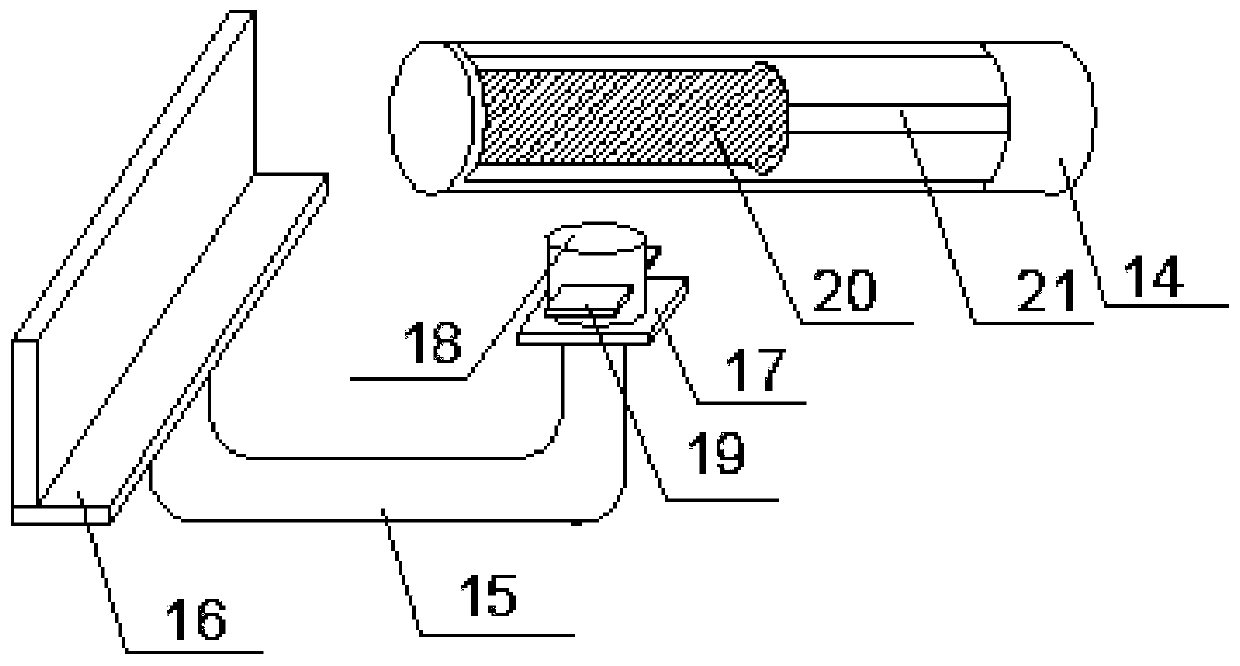

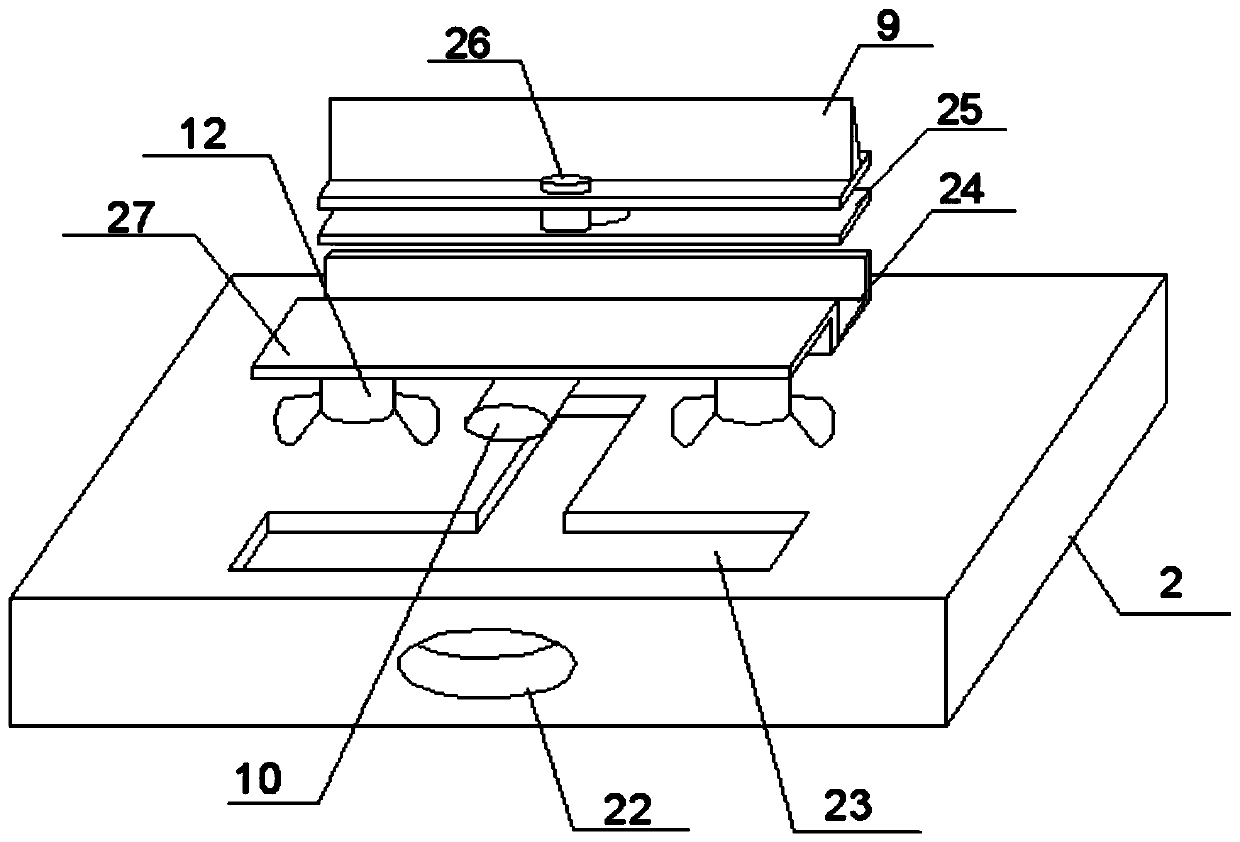

[0031] Place the workpiece to be punched on the fixed plate 6, and the extrusion plate 16 squeezes and fixes the punched workpiece. According to the type of blanking, adjust the position of the blade 9, that is, loosen the fastening nut 12, and turn the adjustment pin 10 , the blade slot 24 moves in the blade moving slot 23 and drives the blade 9 to move back and forth. After being adjusted to a suitable position, tighten the fastening nut 12 to fix the blade slot 24 to achieve the purpose of fixing the blade 9.

[0032] Turn on the hydraulic switch 4, the hydraulic cylinder 3 works and drives the stamping plate 2 to carry out the stamping operation.

[0033] Step on the extrusion column 28 downwards, the gas in the U-shaped cylinder 31 pushes the rotating shaft 5 upwards, the limit rod 29 breaks away from the limit groove 8, rotates the fixed plate 6, and adjusts the position of the blanking workpiece; loosen the extrusion column 28 Due to the pressure, the rotating shaft 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com