Fixed-length rapid cutting device for data line production and processing

A fast cutting and data line technology, applied in the direction of line/collector parts, electrical components, connections, etc., can solve the problems of small application range, not significantly improved cutting efficiency, increased labor intensity of employees, etc., to achieve convenience collection of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

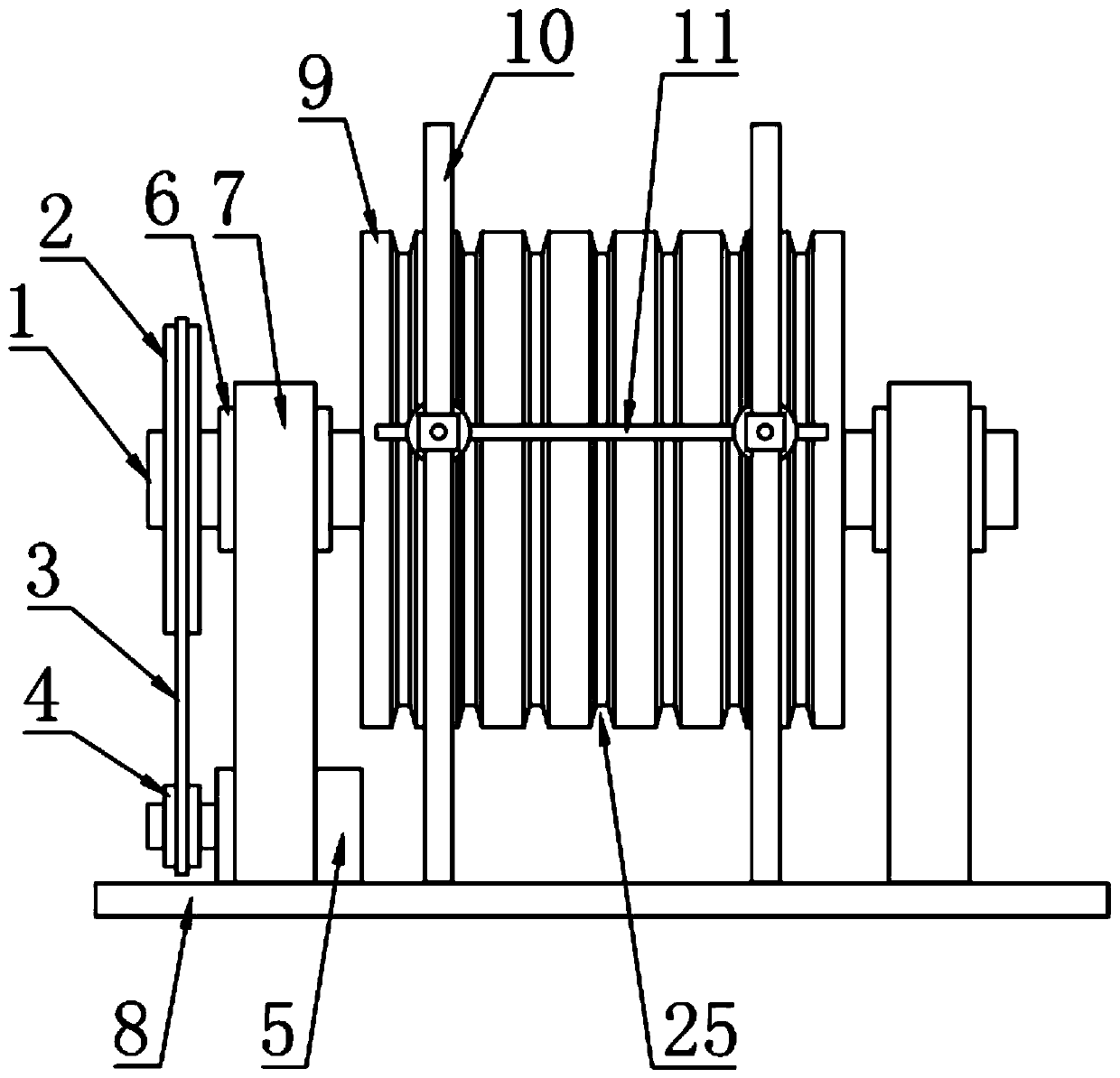

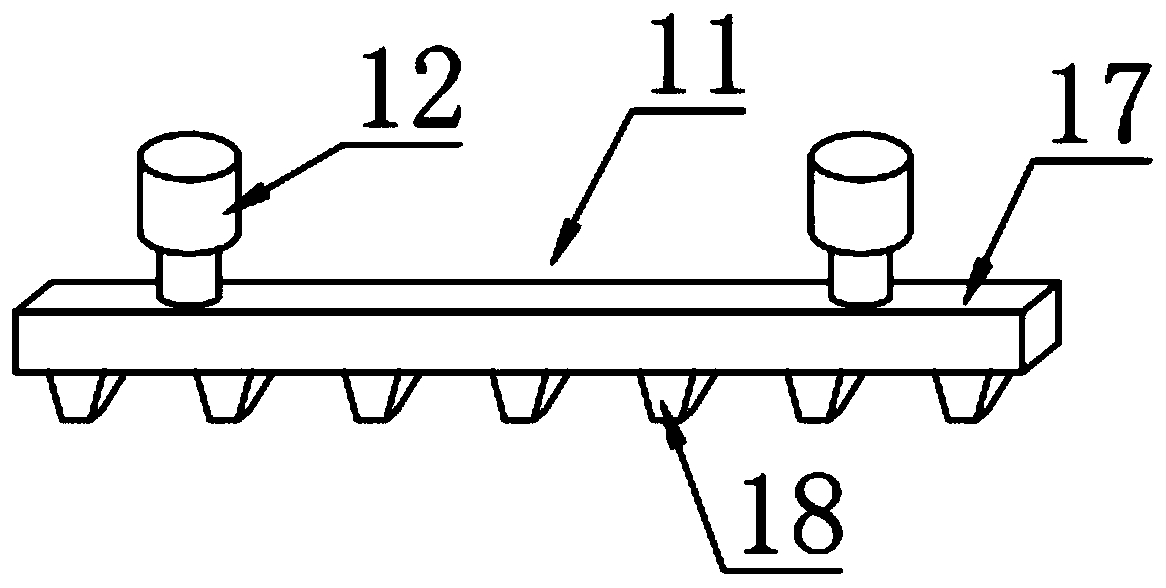

[0023] see Figure 1-5 , in an embodiment of the present invention, a fixed-length rapid cutting device for data line production and processing, including a driving mechanism, a support frame 7, a support shaft 1 and a base 8, and two support frames 7 are fixedly arranged on the base 8, two A support shaft 1 is installed and fixed on the support shaft 1 between the two support frames 7 through the rotation of the bearing 6 on the first support frame 7, and the bobbin 9 is provided with at least one annular winding groove. 25. The support shaft 1 is driven to rotate by a driving mechanism, and at least one cutting support rod 10 is installed on the outside of the bobbin 9, and the two ends of the cutting support rod 10 are fixed on the base 8, and the cutting support rod 10 At least one cutting assembly capable of adjusting and moving along the cutting support rod 10 is installed on it.

[0024] Further, the drive mechanism includes a driven pulley 2, a transmission belt 3, a ...

Embodiment 2

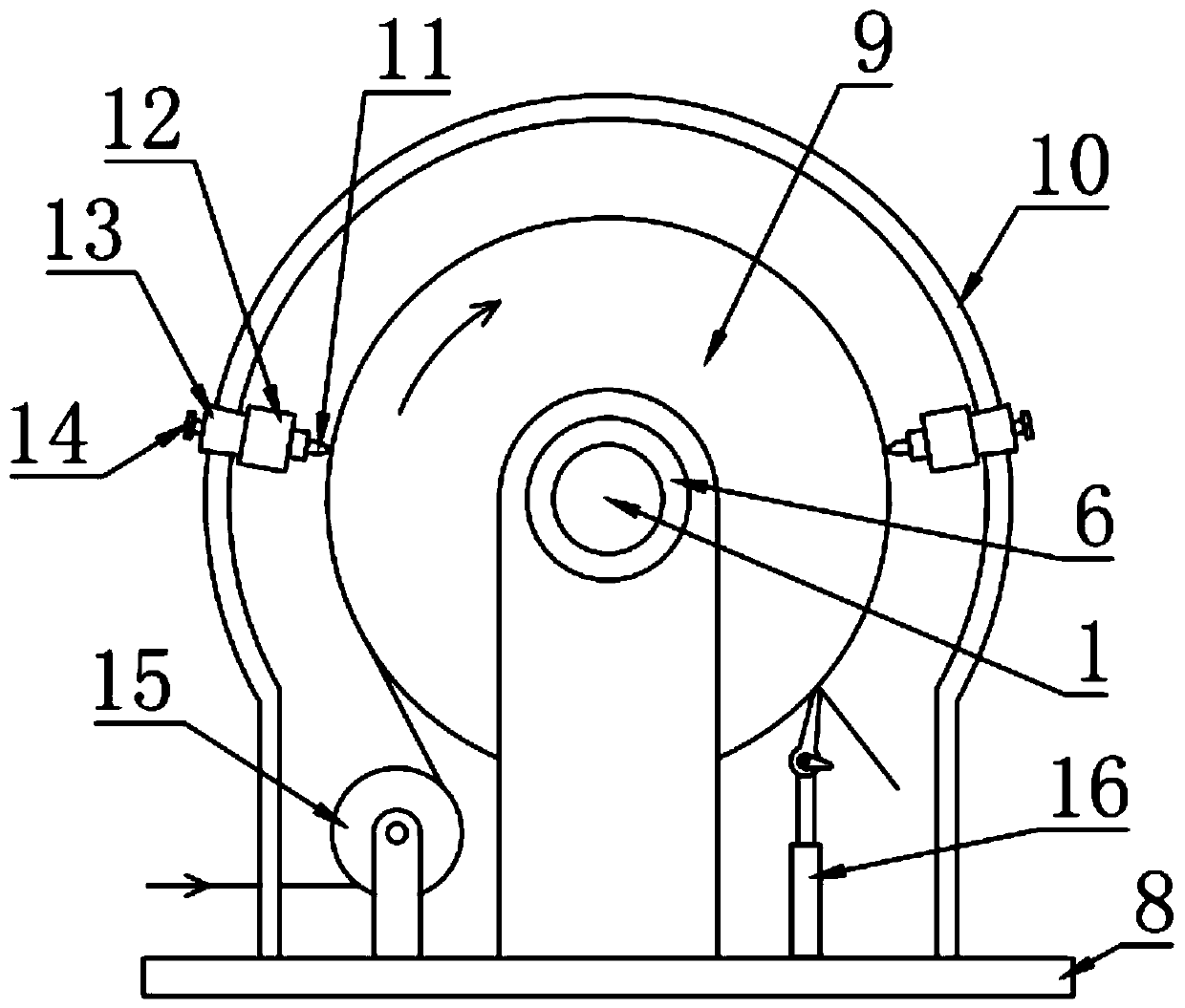

[0029] see figure 2 and 5 , the difference between this embodiment and embodiment 1 is:

[0030] In this embodiment, one side of the bobbin 9 is installed on the base 8 with an incoming wire guide wheel 15 for guiding the data wire 20, and the incoming wire guide wheel 15 can adopt an existing structure; The other side of the cylinder 9 is installed with an outlet shoveling assembly 16 for shoveling out the data wire 20 locked in the annular winding groove 25 .

[0031] Further, the outgoing line shoveling assembly 16 includes a shoveling head 21, a hinge shaft 22, a second adjustment knob 23 and a second telescopic cylinder 24, the second telescopic cylinder 24 is fixedly arranged on the base 8, and the second telescopic cylinder 24 The upper end of the upper end is hinged by a hinge shaft 22 and is provided with a shoveling head 21 matched with the annular winding groove 25, and the upper end of the shoveling head 21 is rounded (to prevent the data line 20 from being dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com