Efficient cutting device

A cutting device, high-efficiency technology, applied in the direction of shearing device, nibbling cutting device, driving device, etc., can solve the problem of low cutting efficiency, achieve the effect of improving cutting efficiency and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

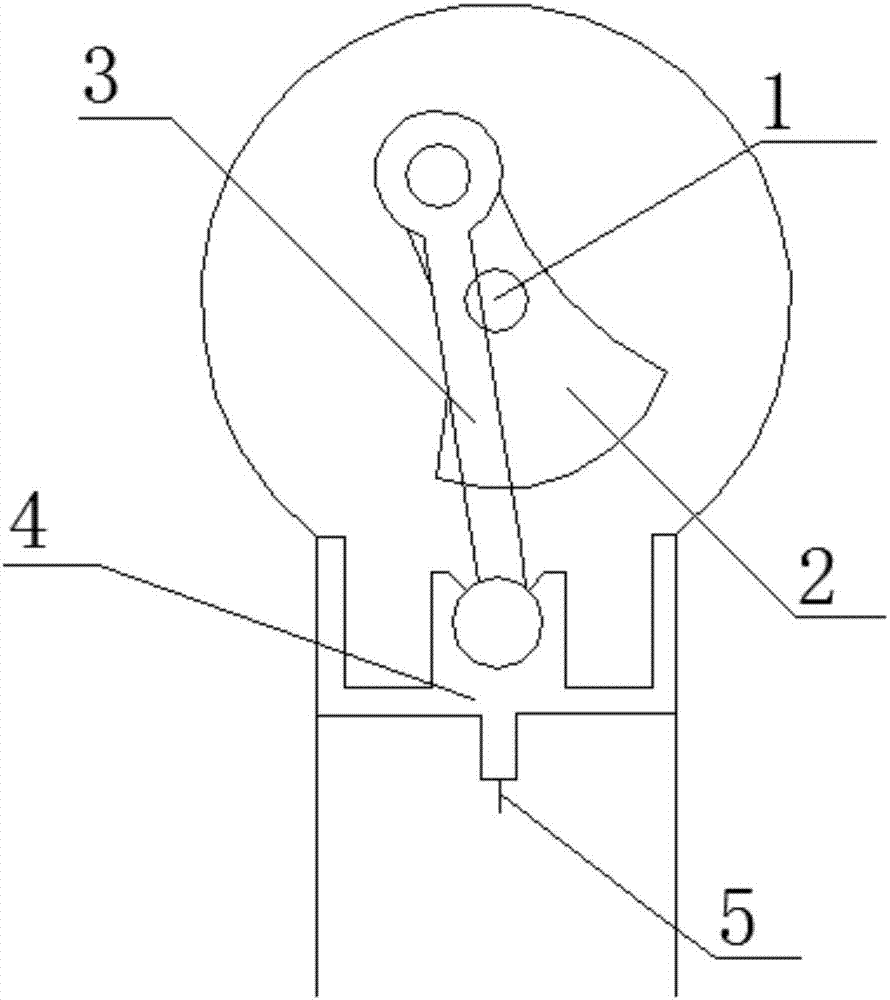

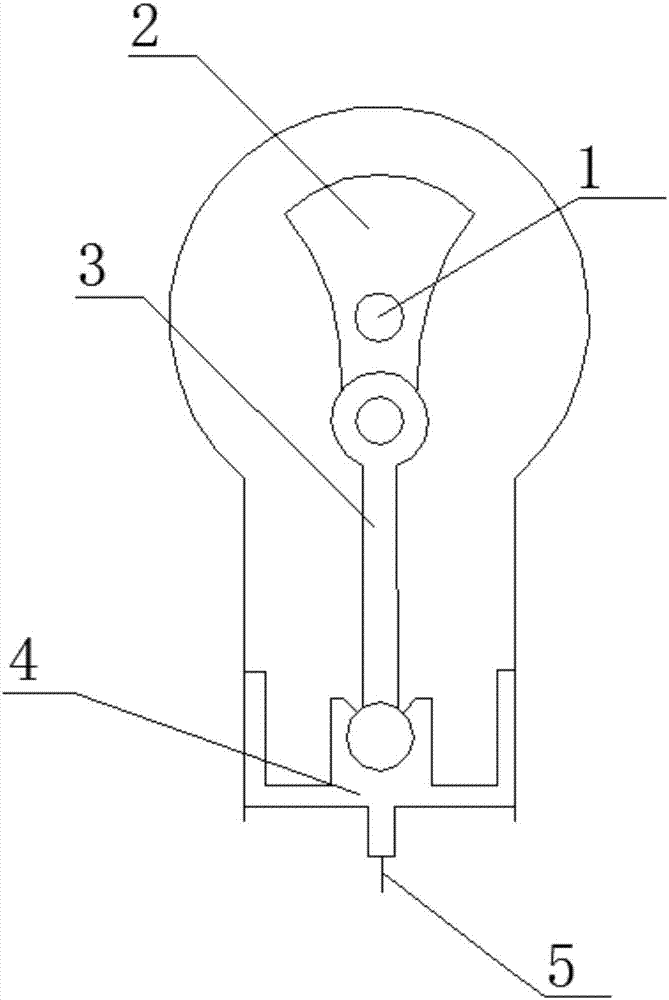

[0021] A high-efficiency cutting device, comprising a body, in which a transmission shaft 1 is arranged, the transmission shaft 1 is connected with a crank 2, one end of the crank 2 is hinged with a connecting rod 3, and the other end of the connecting rod 3 is hinged with a knife rest 4, A cutting knife 5 is arranged on the knife rest 4, and the knife rest 4 can move vertically. Power is output through the transmission shaft 1 to drive the crank 2 to rotate, and then the crank 2 rotates to drive the connecting rod 3 to move, so that the knife holder 4 falls rapidly, and the cutting knife 5 performs cutting work, thereby improving the cutting efficiency.

Embodiment 2

[0023] On the basis of Example 1, the blade thickness of the cutting knife 5 is 3mm-5mm.

Embodiment 3

[0025] Based on the above embodiments, the cutting blade 5 is provided with a WC-10Co4Cr coating. Through this setting, it is possible to prevent the cutting blade 5 from corroding and affecting the cutting efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blade thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com