Water seal slag scraping device for coke-containing powder of coal gas for coke quenching industry

A slag scraping device and coke powder technology, applied in the field of coke quenching, can solve problems such as unsuitable gas, and achieve the effect of facilitating collection, reducing waste of labor and water sources, and facilitating transportation or reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

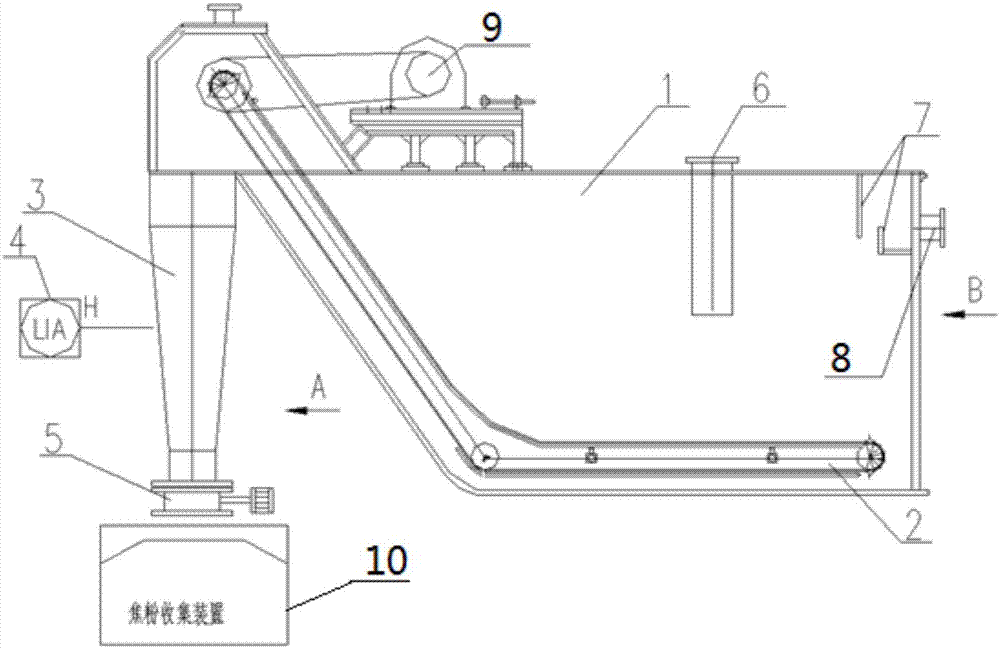

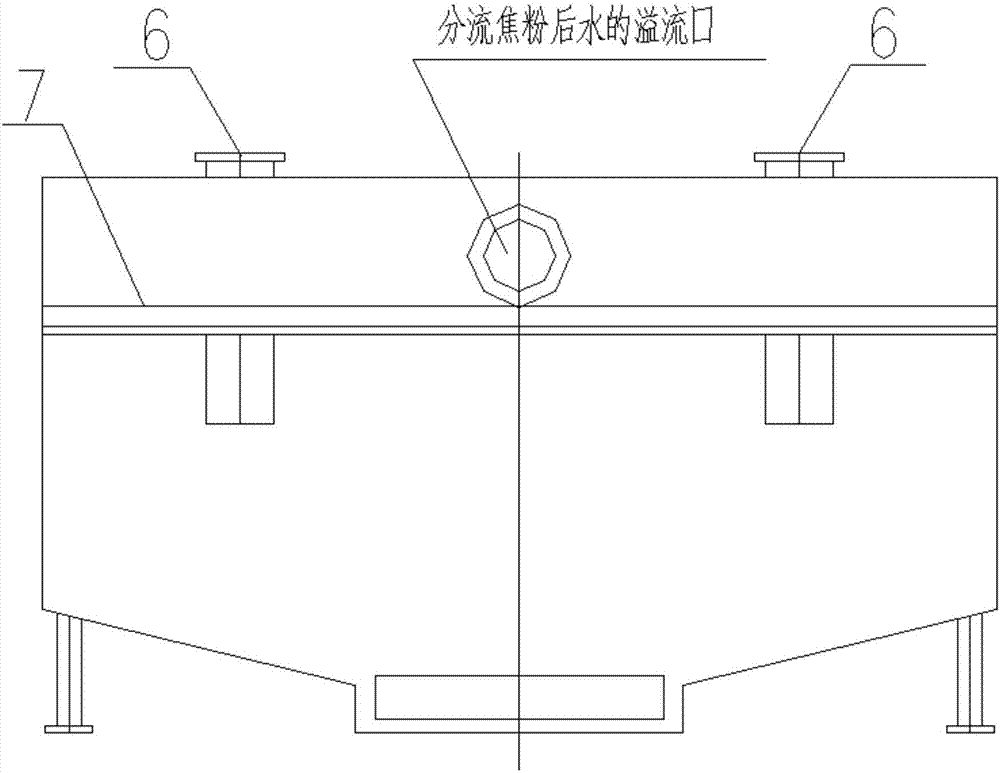

[0042] This embodiment discloses a slag scraping device applied to the coke quenching industry, such as Figure 1-3 As shown, the water-sealed slag scraping device for coal gas containing coke powder used in the coke quenching industry provided by the present invention includes a slag scraping tank 1 for holding coke powder water and providing coke powder settlement space;

[0043] A slag scraper 2 is installed at the bottom of the slag scraper 1 to scrape out coke powder in the slag scraper;

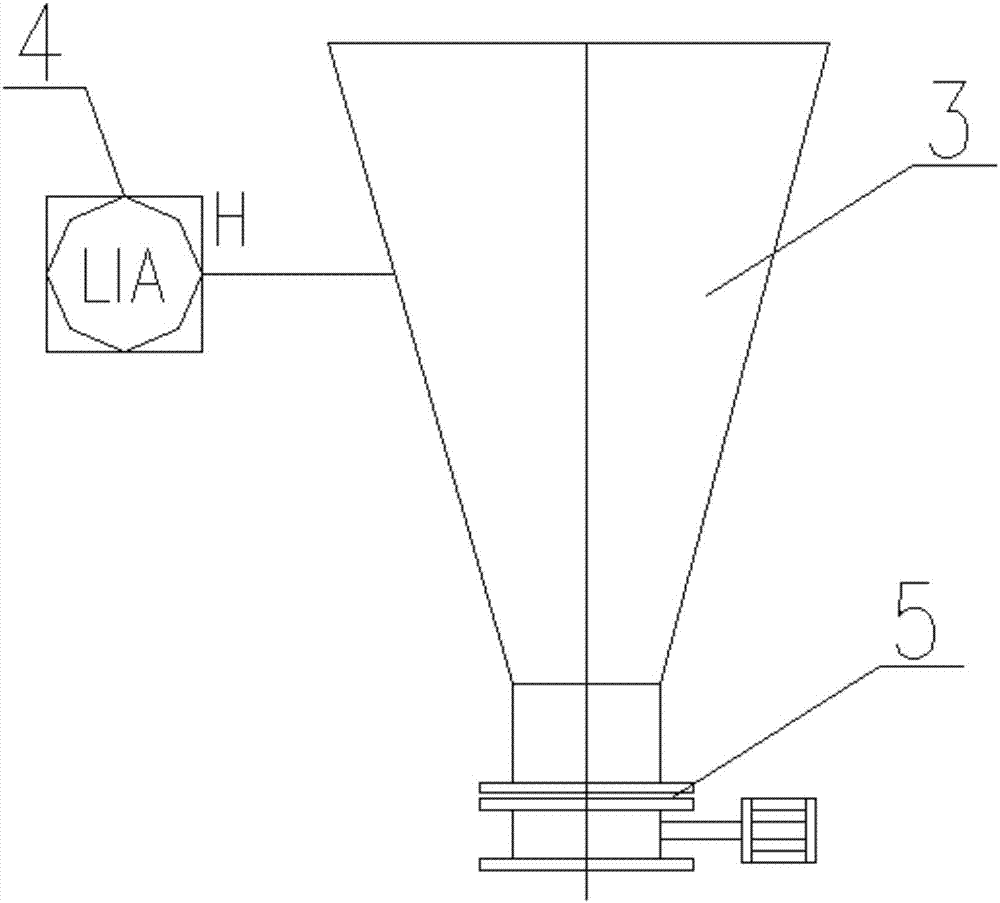

[0044] The ash storage bin 3 is used to store the coke powder scraped by the slag scraper;

[0045] The slag scraper 2 is also provided with a chain conveyor, and the coke powder scraped by the slag scraper 2 is transported to the top of the ash storage bin 3 through the chain conveyor.

[0046] The water seal slag scraping device is in the shape of a high-heeled shoe that seals the shoe opening, including

[0047] The slag scraping tank 1 is located in the front middle of the high-he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com