Detonating tube collection buffering device

The technology of a buffer device and a detonator is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, which can solve the problems of reduced production efficiency, loose collection of detonators, and unstable quality of detonators. Achieve the effect of ensuring production quality, improving production efficiency and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

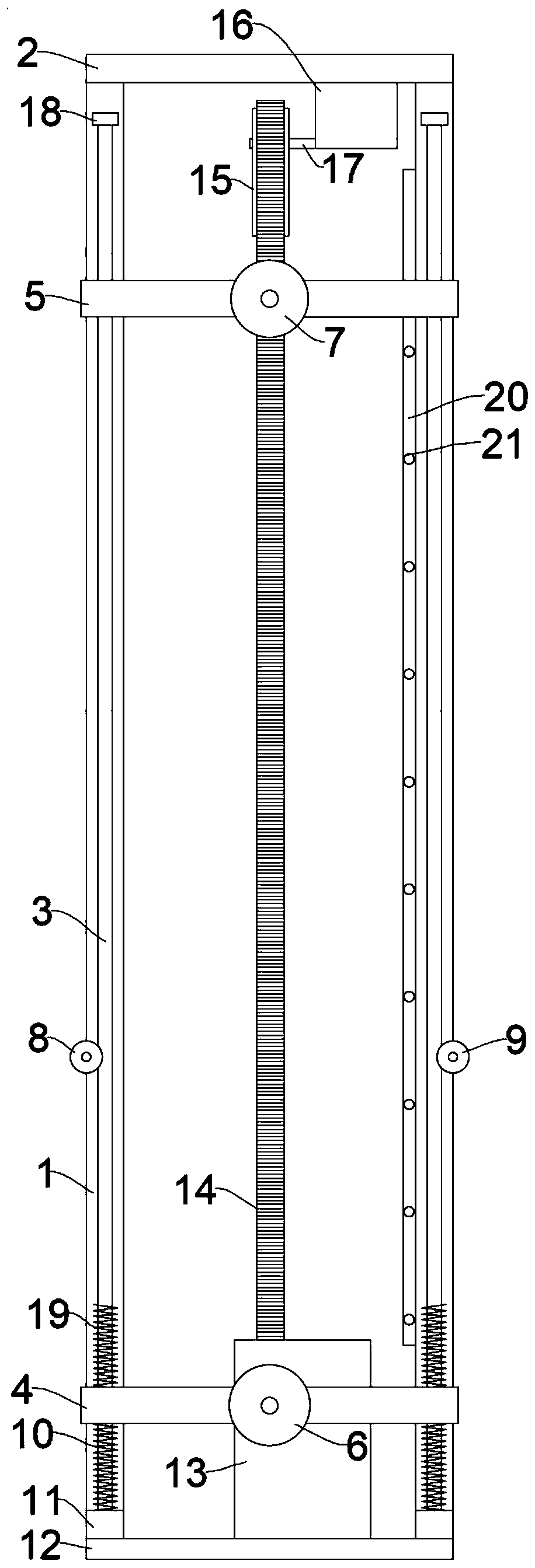

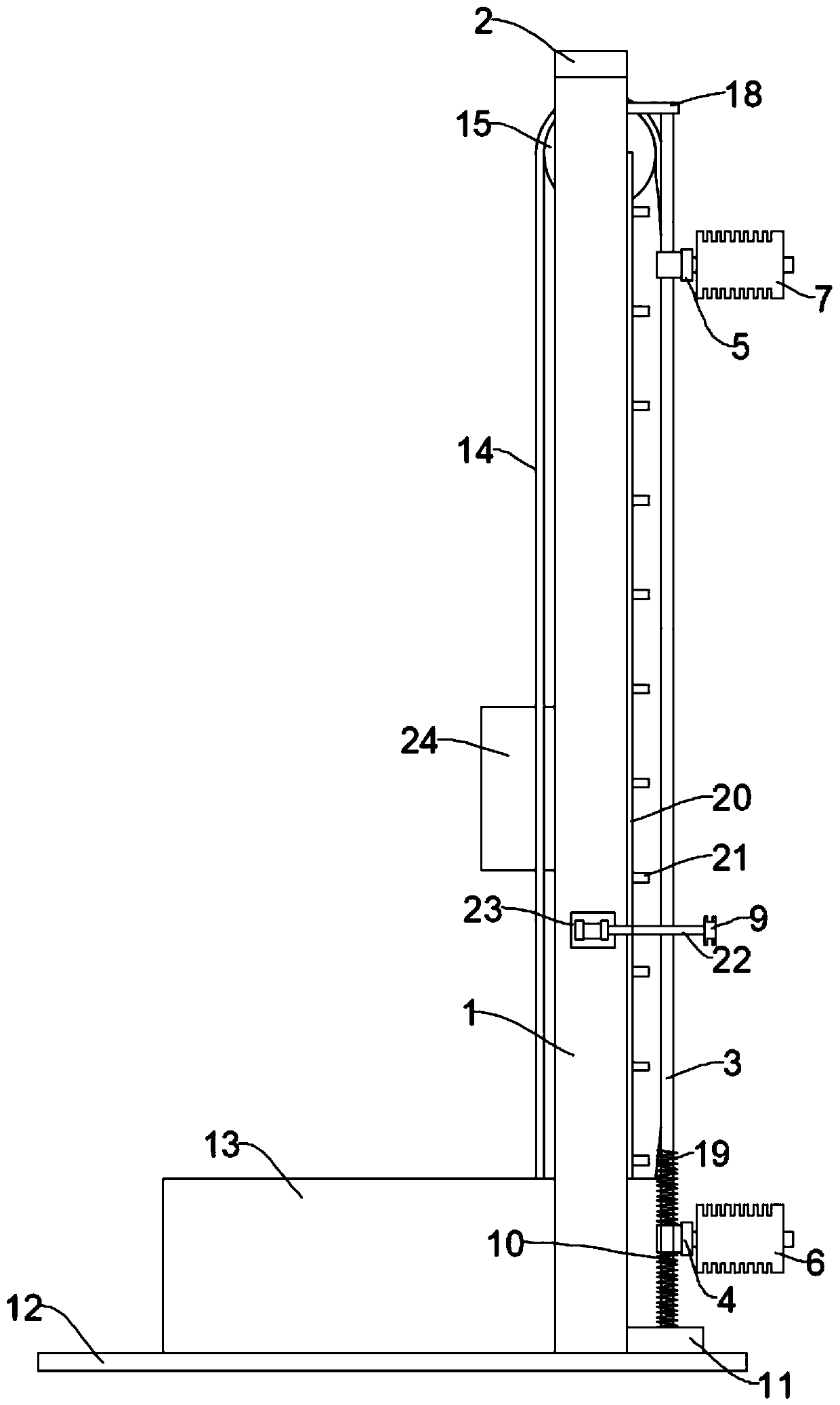

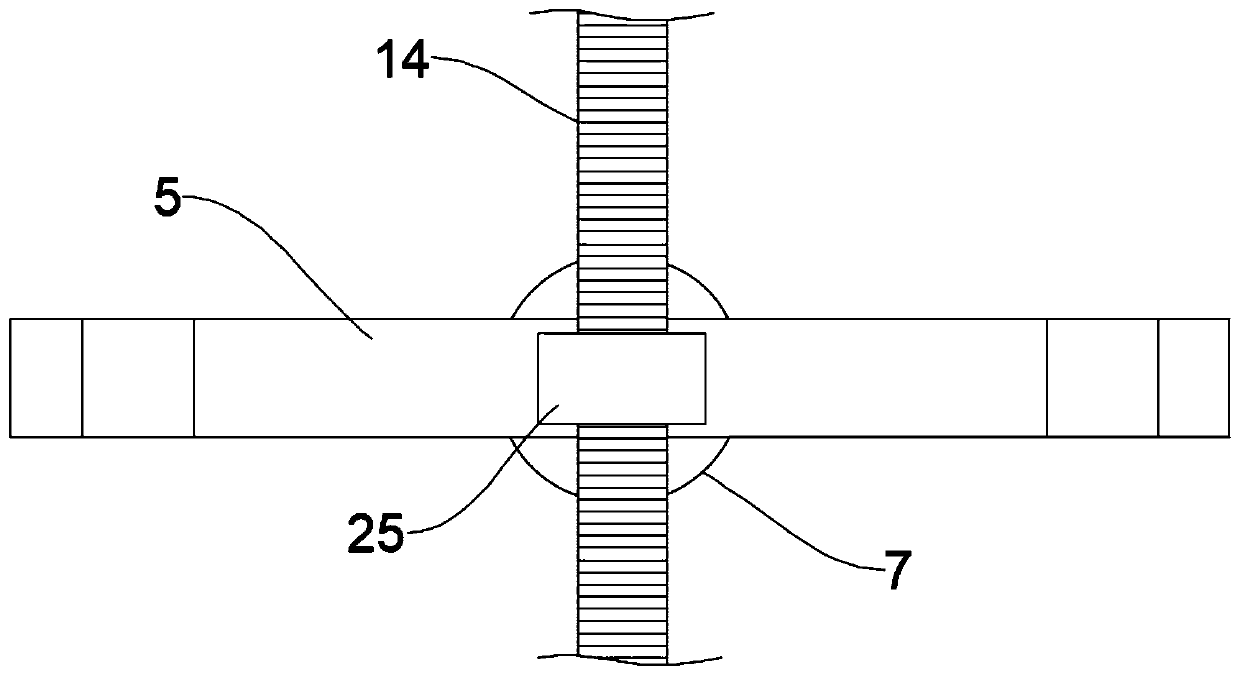

[0035] Such as Figure 1-Figure 4 As shown, the present embodiment provides a nonel receiving buffer device, comprising: a frame body, two vertically arranged slide bars 3, a first slide 4, a second slide 5 and a driving device.

[0036]The frame body is arranged vertically, and the frame body includes two opposite fixed columns 1, a top seat 2 and a base 12, the lower ends of the two fixed columns 1 are fixedly connected with the upper surface of the base 12 respectively, and the upper ends of the two fixed columns 1 are respectively It is fixedly connected with the lower surface of the top base 2, wherein the base 12 is a flat plate, and the base 12 is provided with a plurality of fixing bolts for easy installation on the ground. The top base 2 is a rectangular long column, and the two ends of the rectangular long column are respectively connected with two The top of the fixed column 1 is fixedly connected. Two slide bars 3 are relatively arranged on one side of the two fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com