Waste compression device

A compression device and waste material technology, applied in the direction of presses, metal processing, manufacturing tools, etc., can solve the problems of large internal gaps, frequent replacement of collection bags, unfavorable transfer and storage, etc., and achieve the effect of facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

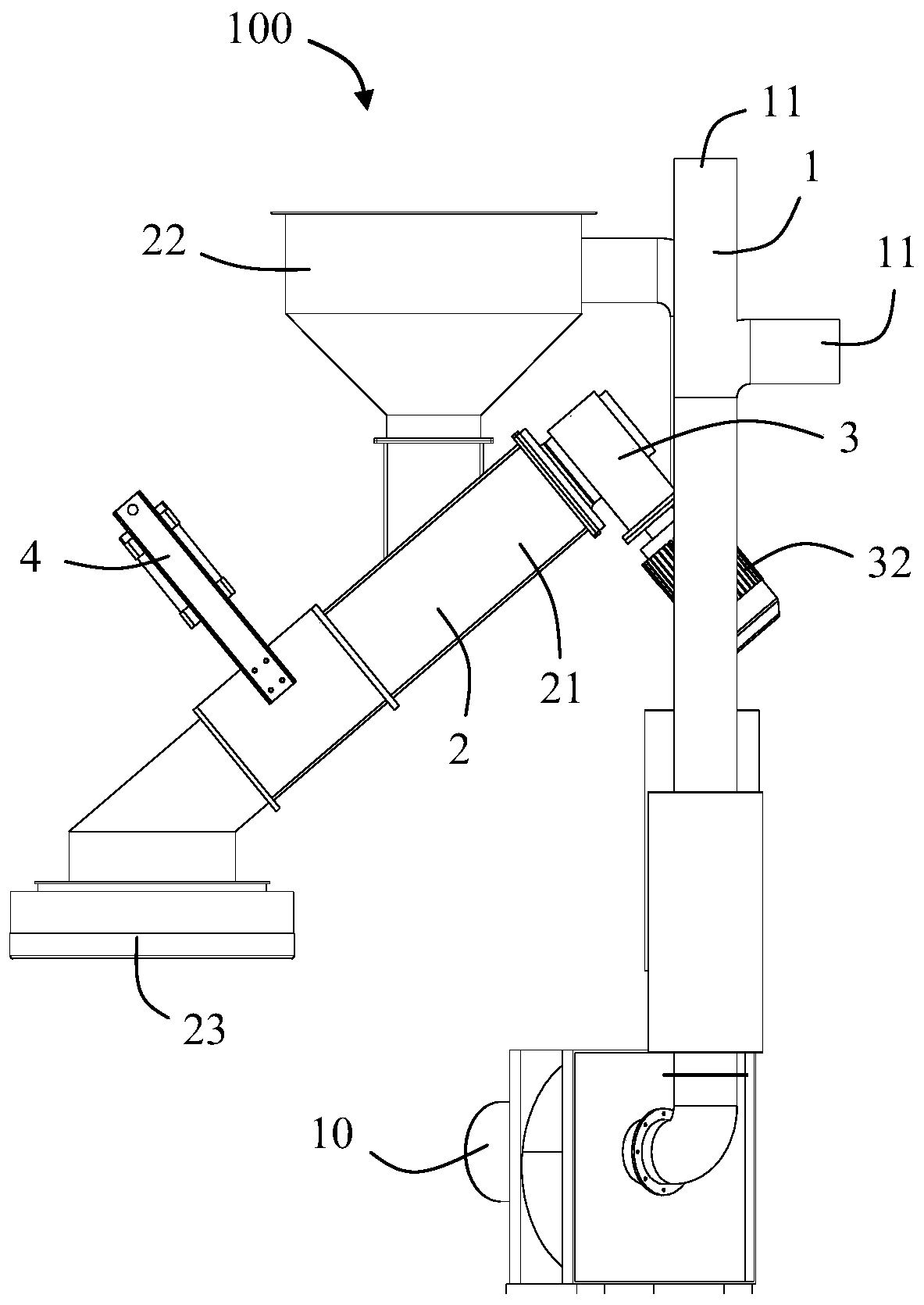

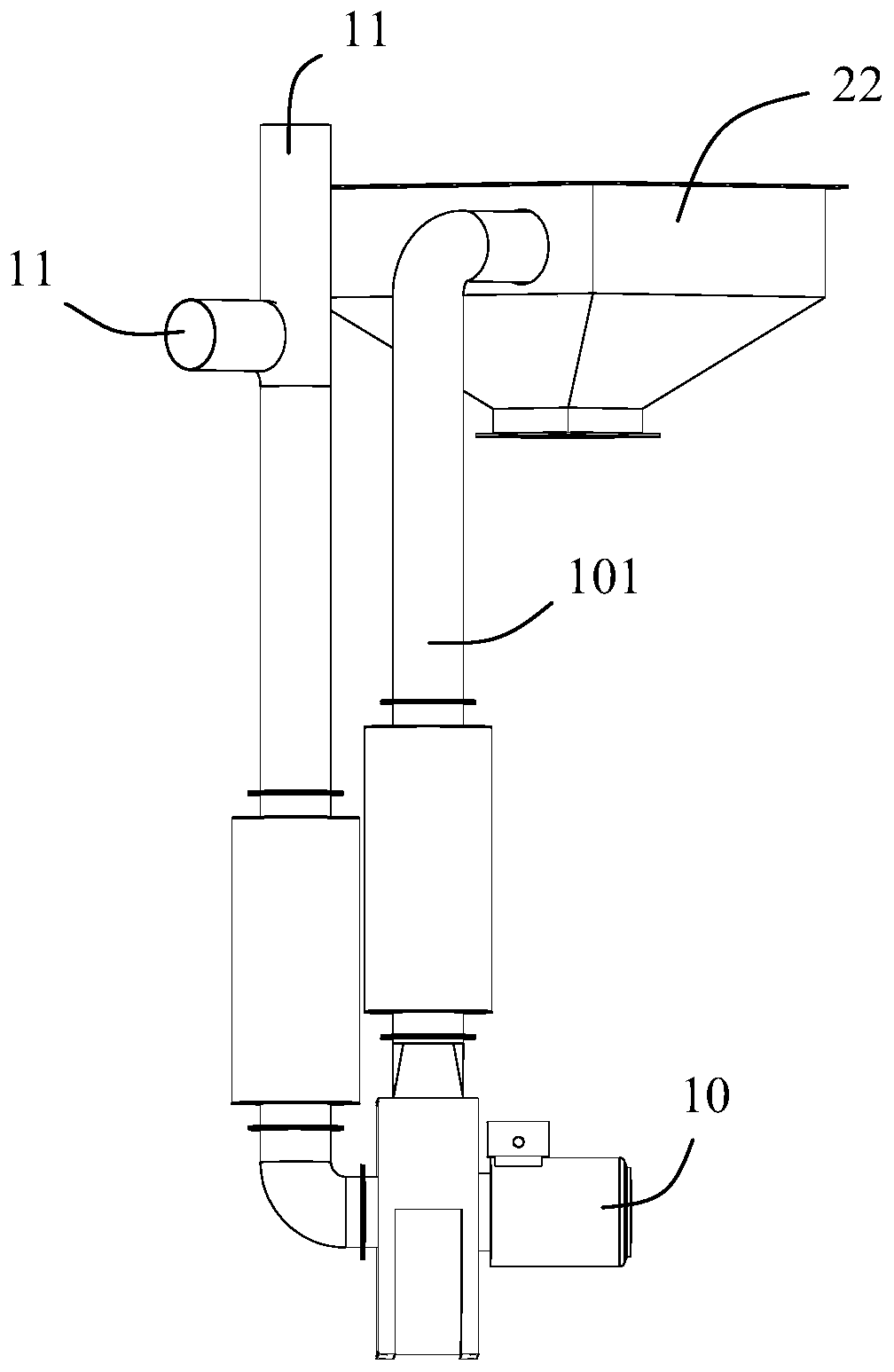

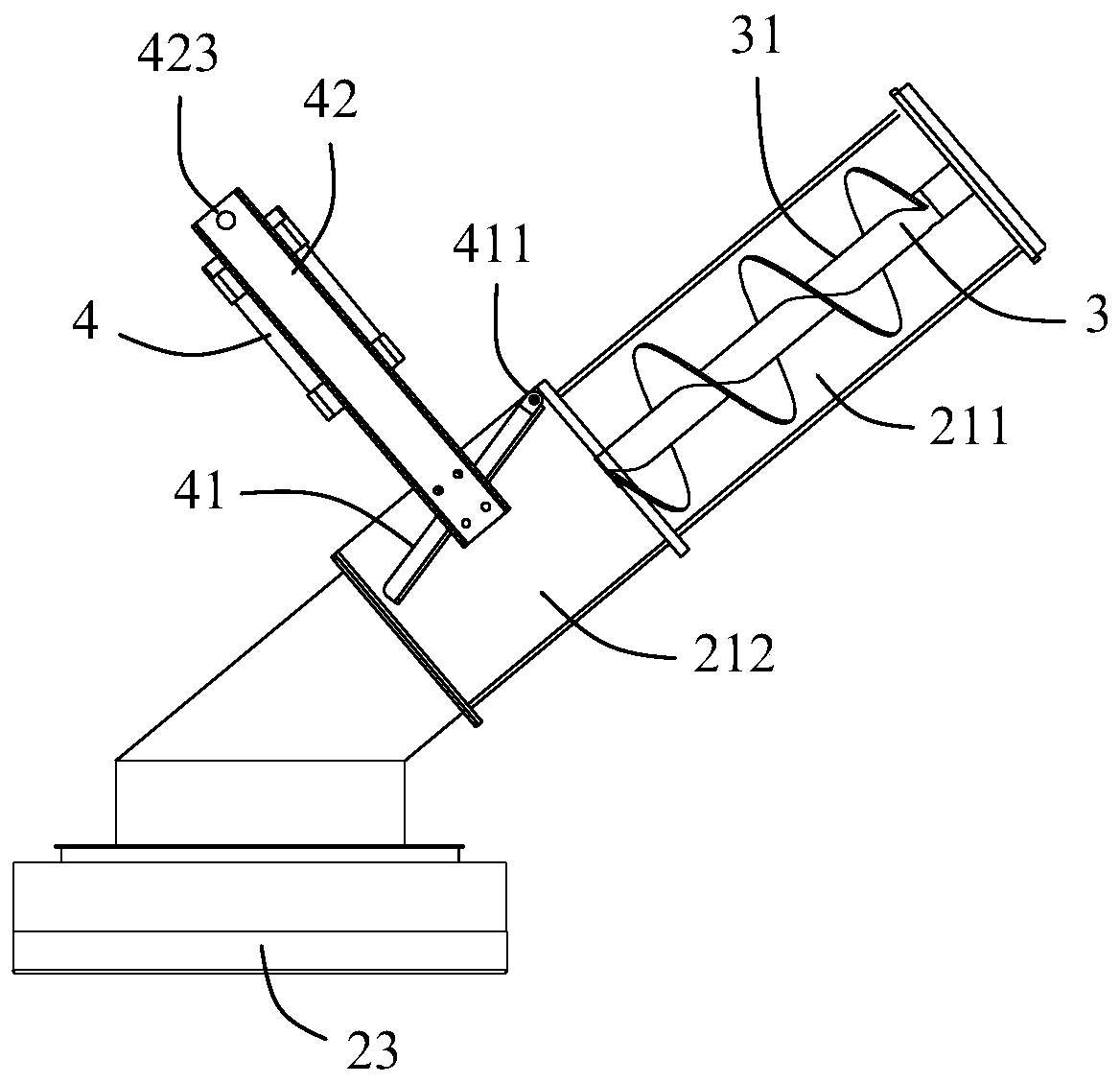

[0021] Please refer to Figure 1 to Figure 5 As shown, the present invention discloses a waste material compression device 100 , which includes a waste material collection part 1 and a waste material compression part 2 , wherein the waste material collection part 1 includes a waste material collection driving device and a waste material inlet 11 . The waste collection driving device is used to provide a power source to make waste enter the waste material inlet 11 . In the illustrated embodiment of the present invention, the waste collection driving device is a blower 10, and the blower 10 is connected to the waste feed port 11 through a pipeline for sucking waste to be collected.

[0022] The waste compression part 2 includes a discharge pipeline 21 connected to the waste material inlet 11 and a first compression mechanism 3 and a second compression mechanism for compressing the waste in the discharge pipeline 21 twice. 4. In one embodiment of the present invention, the blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com