Rotary-forging forming and feeding device for internal thread pipe

A technology of feeding device and internal thread, used in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., to achieve the effect of high-precision rotary forging, good forming quality, and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

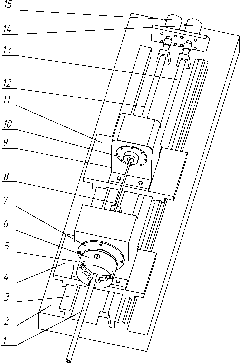

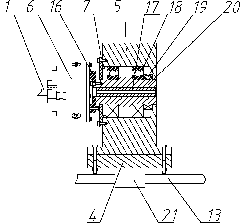

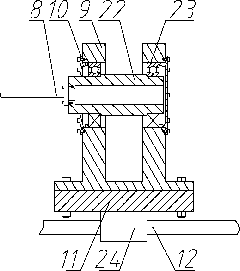

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] refer to figure 1 , a feeding device for internally threaded pipe swaging, including a feeding mechanism and a mandrel action mechanism, the lower rail surface of the feeding table 4 in the feeding mechanism cooperates with the upper rail surface of the guide rail 3, and the mandrel feeding table in the mandrel action mechanism The lower guide rail surface of 11 cooperates with the upper guide rail surface of guide rail 3, and guide rail 3 is installed on the bed 2, and the first servo motor and reducer 14, the second servo motor and reducer 15 are respectively fixed on the bed 2 with screws. The tail is connected to the first ball screw 13 and the second ball screw 12 respectively through a coupling;

[0023] refer to figure 1 with figure 2 , the feeding mechanism includes a three-jaw chuck 6, the workpiece 1 is fixed by the claws on the three-jaw chuck 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com