Welding tool of anti-collision beam and mounting plate

A welding tooling and mounting plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor dimensional repeatability, low efficiency, unable to meet the requirements of size and flatness, and achieve reliable clamping. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

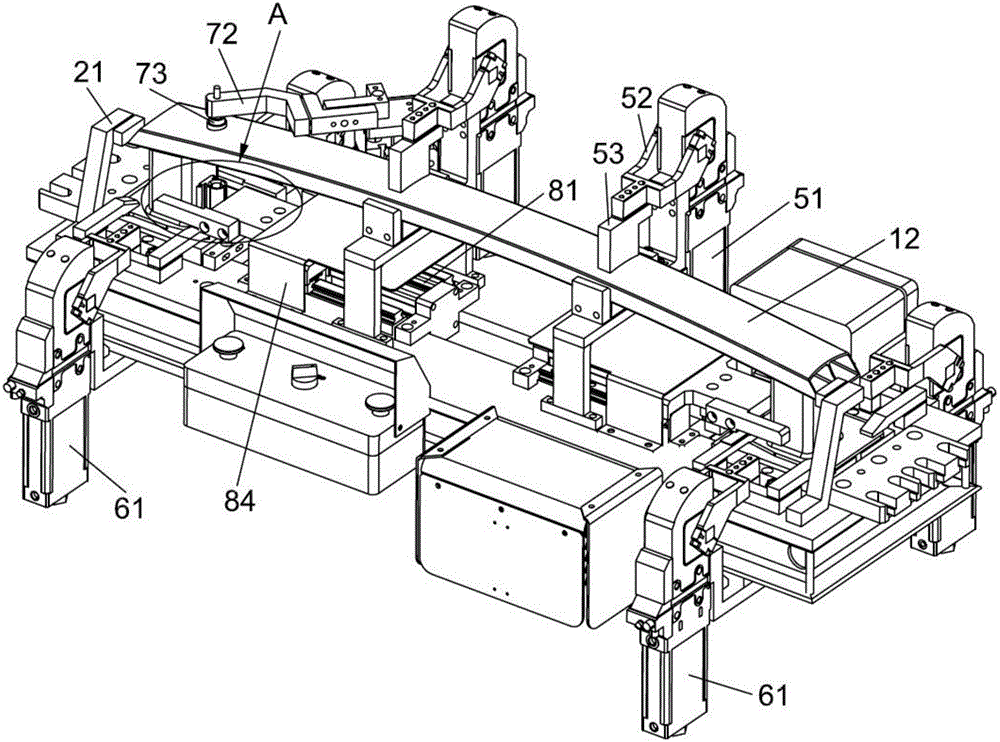

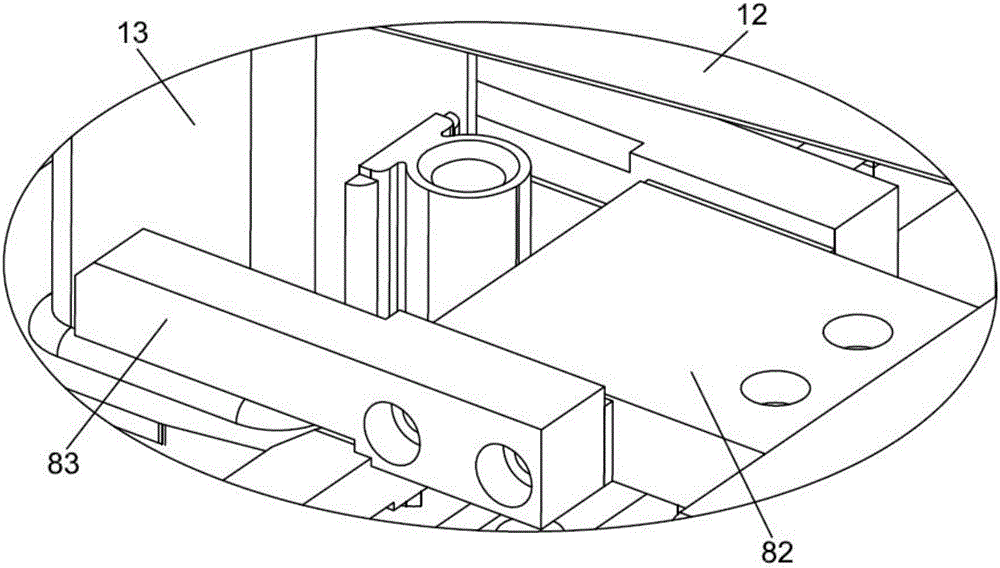

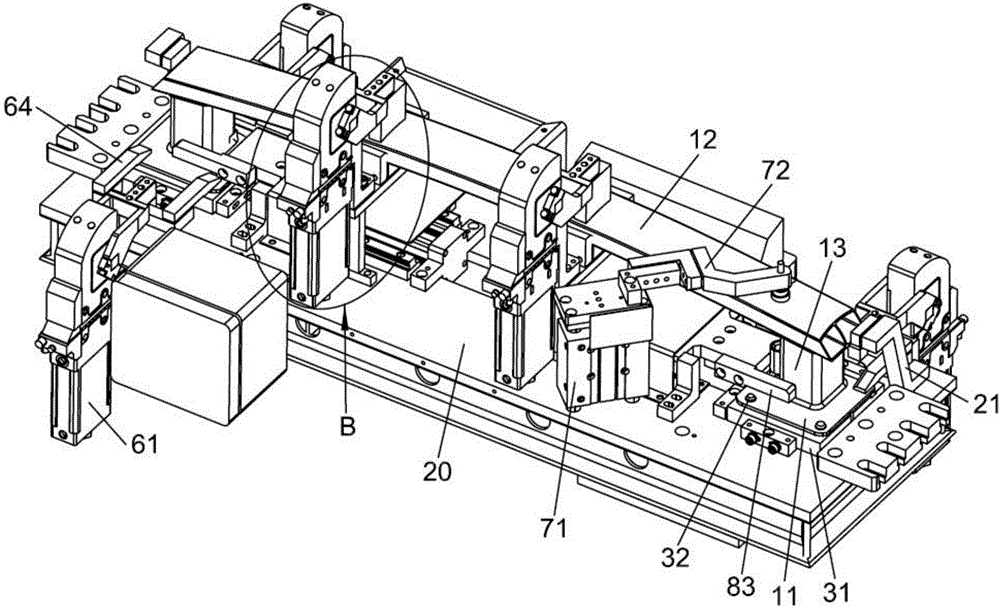

[0023] refer to Figure 1 to Figure 7 , the present invention provides a welding tool for an anti-collision beam and a mounting plate, including a mounting plate body 11 and a welded anti-collision beam 12 and an energy-absorbing box 13, the mounting plate body 11 is provided with a positioning hole 15, including a mounting platform 20 , the installation platform 20 is provided with a support platform 31, a support assembly, a first pressing assembly and a pair of end positioning blocks 21, the end positioning blocks 21 are fixedly connected with the installation platform 20, and the end of the anti-collision beam 12 is against the end Positioning block 21 surface; Support platform 31 is provided with positioning column 32, and mounting plate body 11 is arranged on support platform 31 upper surfaces, and positioning column 32 is arranged in the positioning hole 15, and supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com